Basement bottom plate pre-laying anti-sticking TPO waterproof coiled material construction method

A technology for basement floor and waterproofing membrane, which is applied in infrastructure engineering, protection devices, gaskets, etc., can solve the problems of poor acid, alkali and salt resistance to high and low temperature, blind spots in waterproof construction, and poor weather resistance, etc. Excellent, reduce waterproof construction cost and construction period, ensure waterproof quality and service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

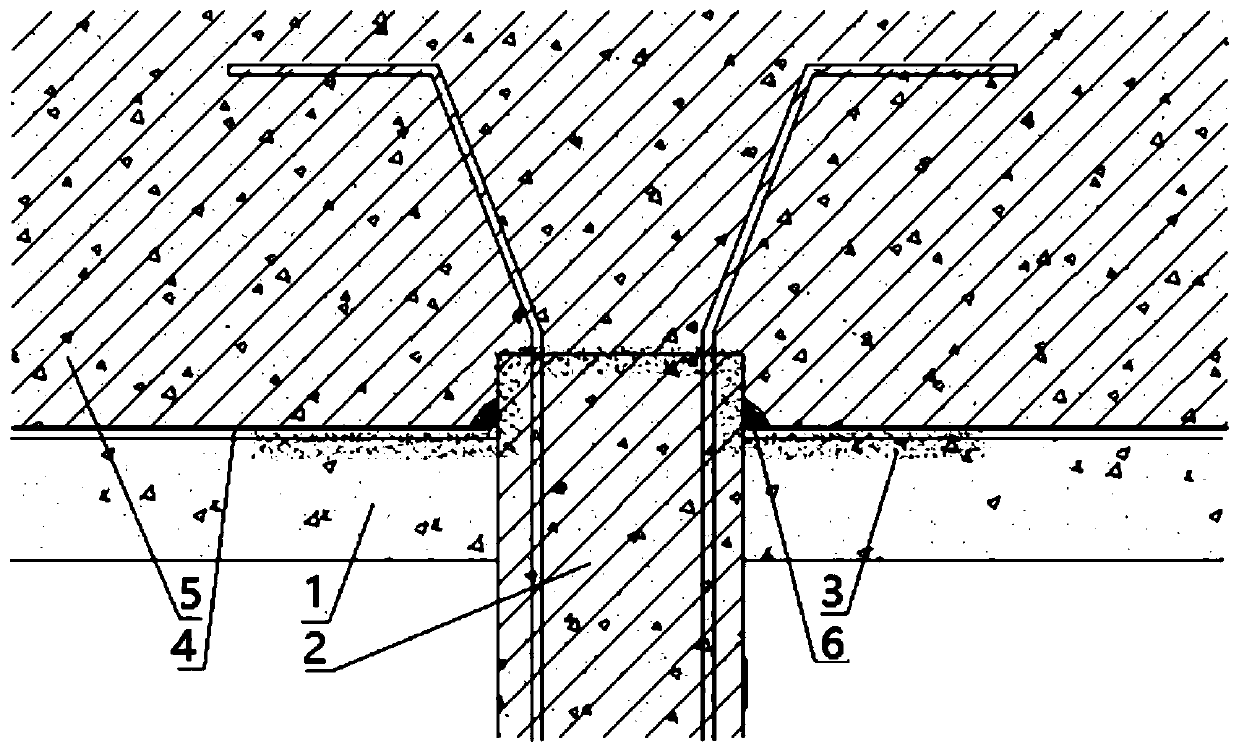

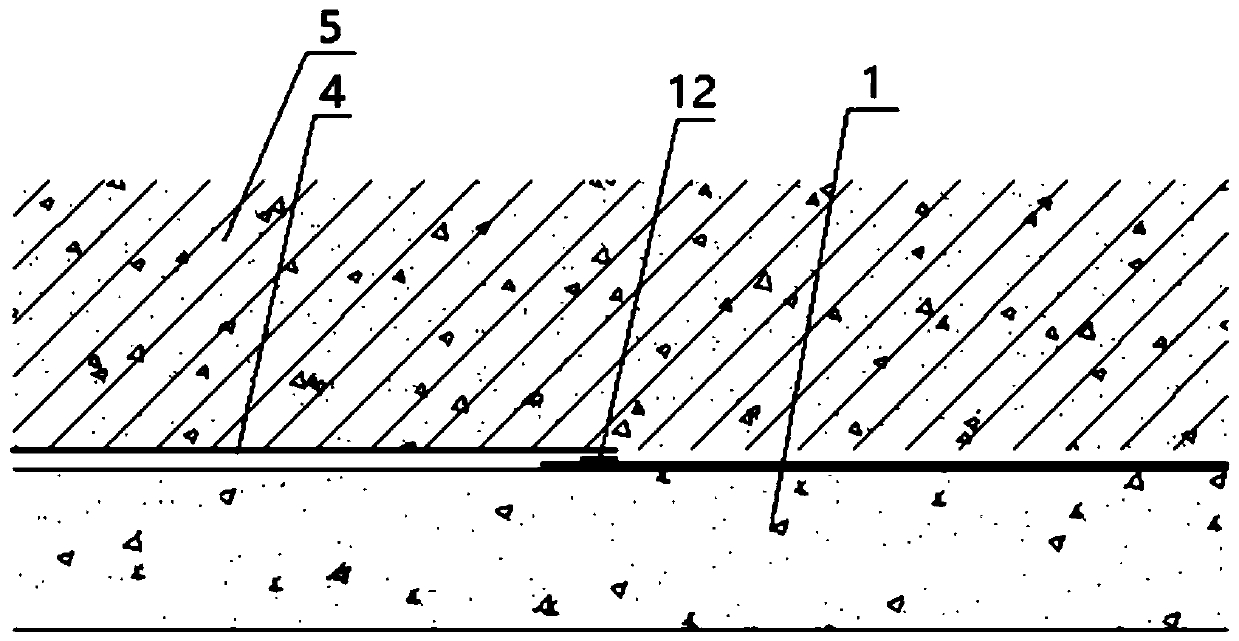

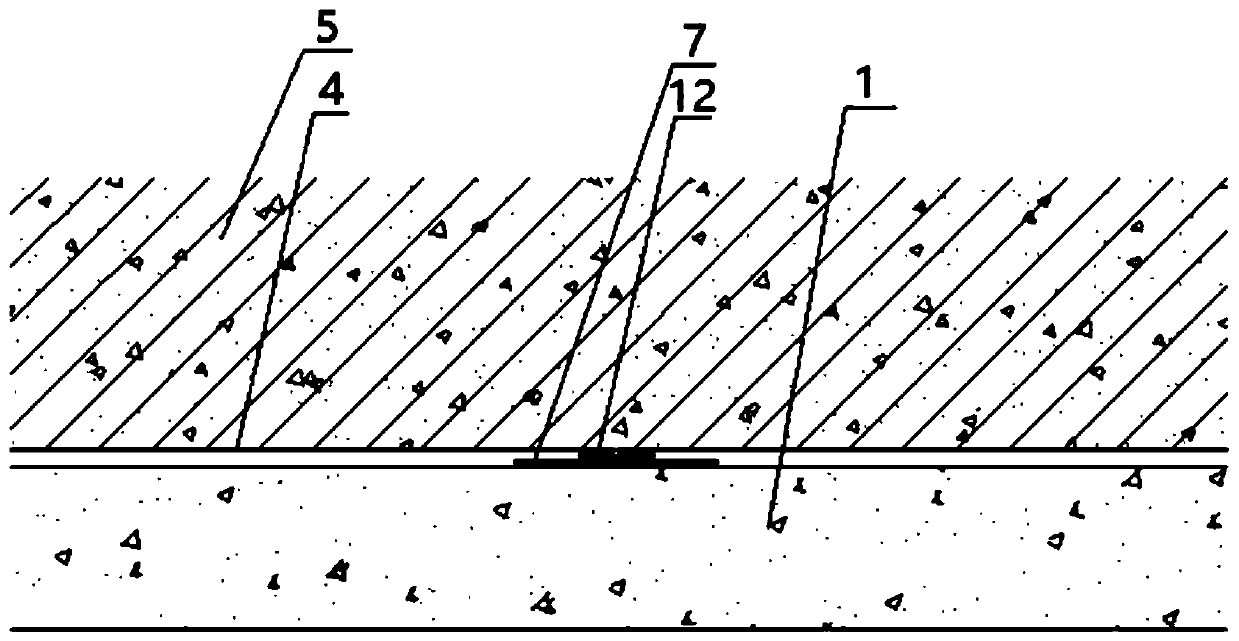

[0086] Such as Figure 1 to Figure 5 As shown, the present invention provides a kind of construction method of anti-adhesive TPO waterproof coiled material pre-laying basement floor, comprising:

[0087] Step 1, base layer 1 treatment: treat the inner corner of the base layer and the outer corner of the base layer into an arc shape or a slope angle;

[0088] Step 2, processing of pile head 2: cleaning pile head 2, brushing waterproof paint layer 3 on pile head 2 and around pile head 2;

[0089] Step 3, snapping the line: laying out the line on the base layer 1 to pop up the planning line laid by the TPO waterproof membrane 4;

[0090] Step 4. Pre-laying the membrane: pre-lay the TPO waterproof membrane 4 on the base layer 1 according to the planned line;

[0091] Step 5. Welding the seams of the coiled material: welding the seams of the TPO waterproof membrane 4 using hot air welding equipment.

[0092] In this embodiment, in step 1, the slope angle ranges from 40° to 50°. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com