Dual cooling system suitable for large-displacement electro-hydraulic servo actuator

An electro-hydraulic servo and dual cooling technology, which is applied in the testing of machines/structural components, instruments, vibration testing, etc., can solve the problems of complex cooling chamber composition, large structural space, and insufficient heat dissipation, etc., to achieve good work environment, less corrosion, and improved cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

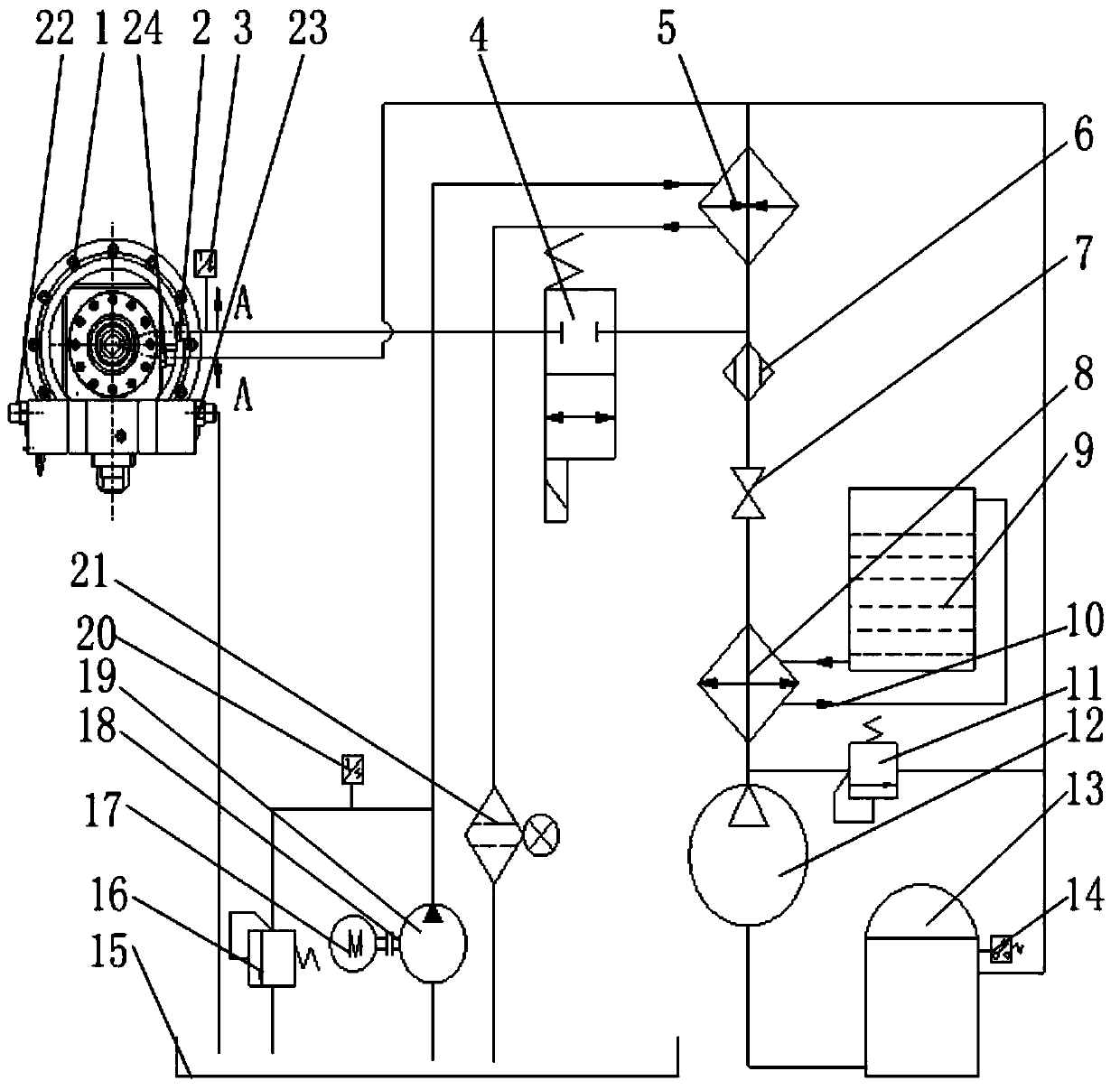

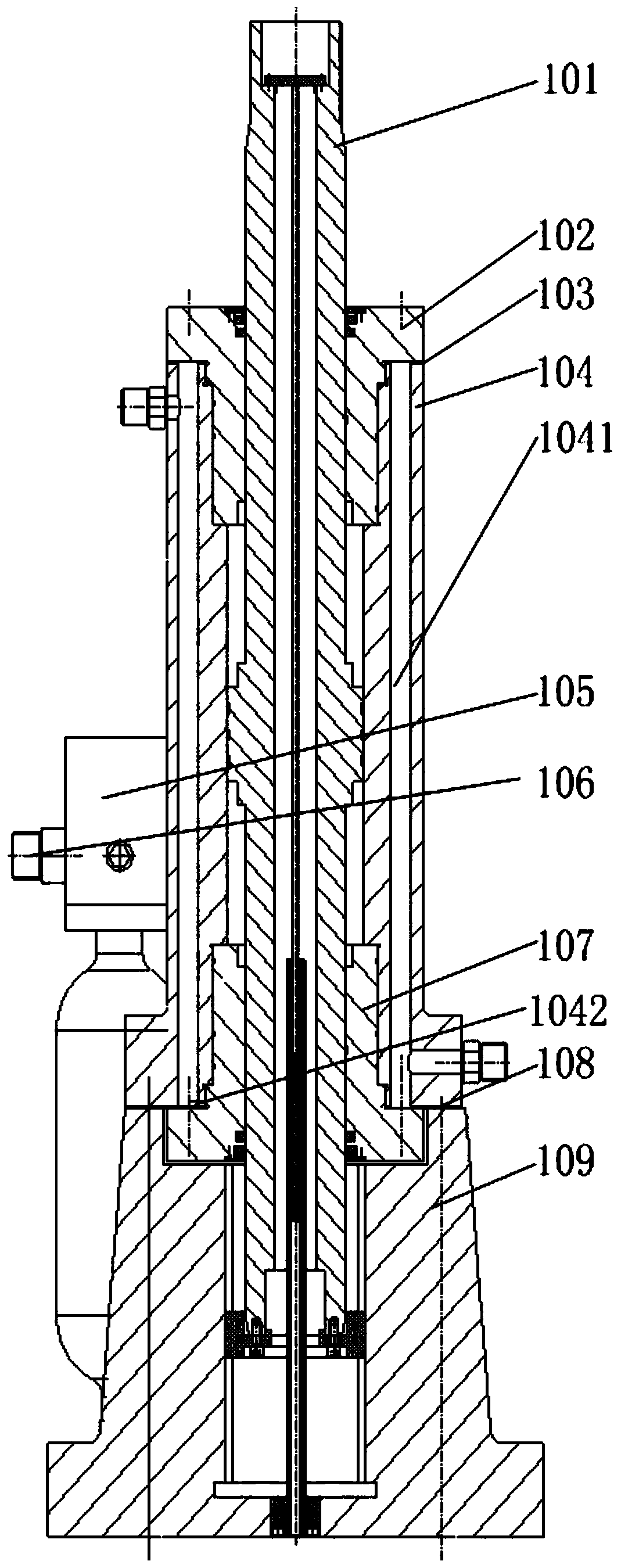

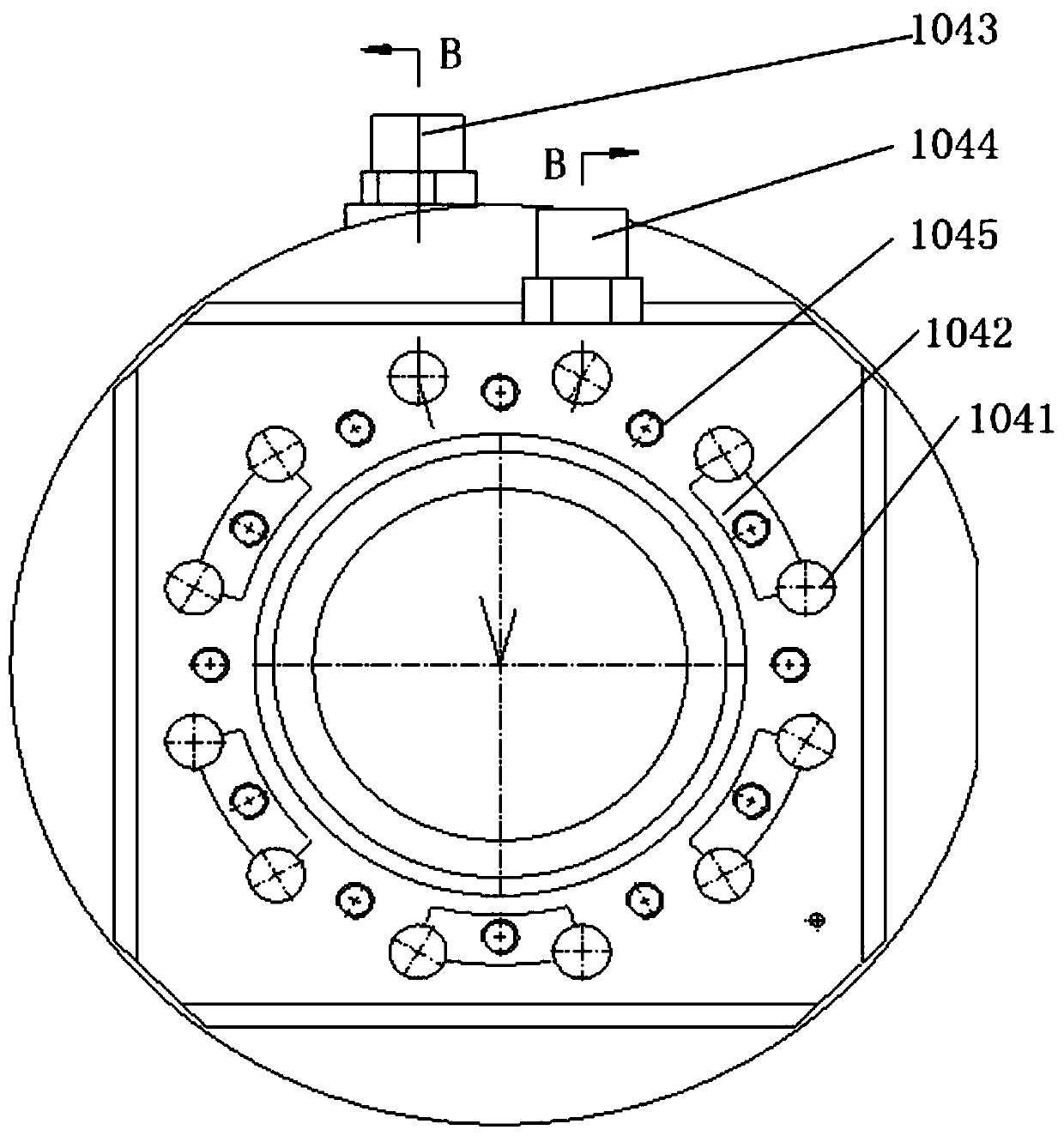

[0035] Such as figure 1As shown, the present invention discloses a dual cooling system suitable for large displacement electro-hydraulic servo actuators, the dual cooling system is used for electro-hydraulic servo actuator 1; the electro-hydraulic servo actuator 1 is connected with an oil inlet 22 and the oil return port 23, the oil return port 23 is directly connected with the oil tank 15 of the large flow pump station through the oil pipe; The oil return port of device 21 is connected. The cold oil pump 19 is connected to the motor 17 through the coupling 18, and the oil outlet of the cold oil pump 19 is respectively connected with the oil inlet of the oil cooling pressure limiting valve 16, the oil temperature and oil pressure integrated sensor 20 and the oil inlet of the evaporator 5 through the oil pipe. port connection. The refrigerant inlet of the evaporator 5 is connected to the outlet of the drier 6 and the inlet of the electromagnetic shut-off valve 4 , and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com