Method for preparing positive electrode of aluminum battery through magnetron sputtering

A technology of magnetron sputtering and aluminum batteries, applied in battery electrodes, sputtering coating, secondary batteries, etc., can solve the problems of unsatisfactory chemical properties and complicated preparation process, and achieve good electrochemical performance and simple preparation method , the effect of controlling the electrode loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1. Cut the high-purity molybdenum sheet into 1cm×1cm slices, and then ultrasonically clean them in deionized water, acetone and absolute ethanol for 20 minutes, then take it out and blow dry with high-purity nitrogen, and place it in Process in a vacuum drying oven. Finally, stick it on the magnetron sputtering sample tray, install the tellurium target, and prepare for sputtering.

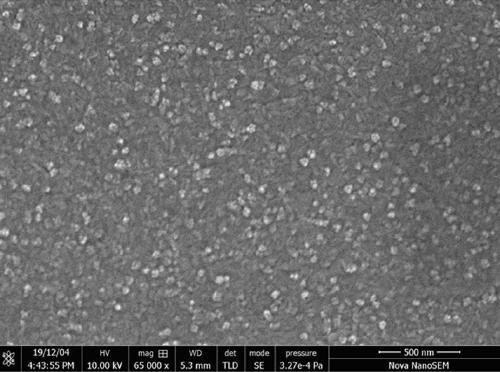

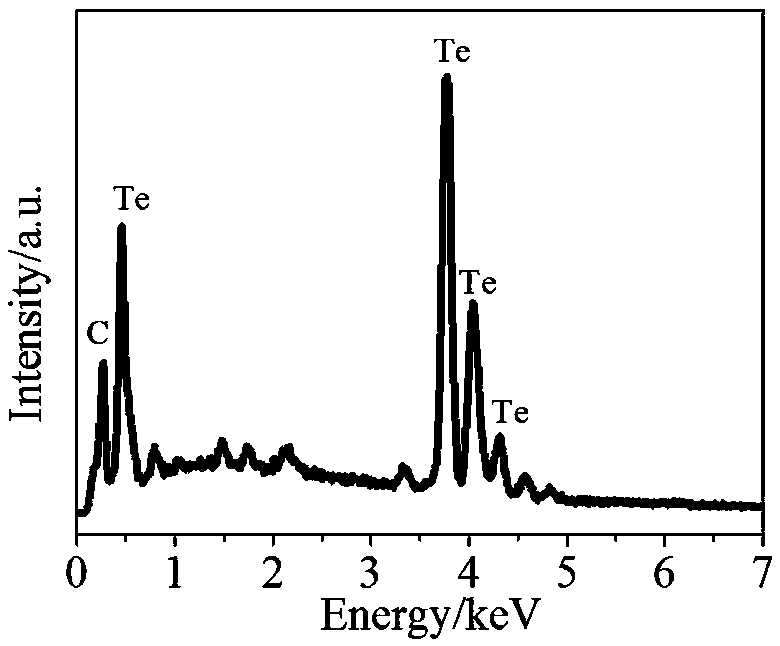

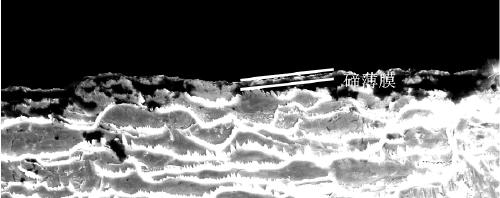

[0024] Step 2. Turn on the magnetron sputtering equipment, vacuum the cavity of the magnetron sputtering equipment, turn on the molecular pump when the resistance unit indicates 5Pa, open the restrictor valve when the composite unit indicates 0.003Pa, and turn on the gas mass flow When the composite unit reads 0.4Pa, open the target baffle. When the DC magnetron sputtering power supply is turned on, turn the current adjustment knob to make the voltage read 100V, the current read 5A, and the power 500W. The sputtering film time is 20min, and the film thickness is 500nm. Finally, the tellur...

Embodiment 2

[0027] Step 1. Cut the high-purity molybdenum sheet into 1cm×2cm slices, and then ultrasonically clean them in deionized water, acetone and absolute ethanol for 20 minutes, then take it out and blow dry with high-purity nitrogen, and place it in Process in a vacuum drying oven. Finally, stick it on the magnetron sputtering sample tray, install the tellurium target, and prepare for sputtering.

[0028] Step 2: Turn on the magnetron sputtering equipment, vacuum the cavity of the magnetron sputtering equipment, turn on the molecular pump when the resistance unit indicates 3Pa, and turn on the restrictor valve when the composite unit indicates 0.001Pa to open the gas quality For the flowmeter, open the target baffle when the composite unit reads 0.2Pa, and when the DC magnetron sputtering power supply is turned on, turn the current adjustment knob to make the voltage read 100V, the current read 8A, and the power 800W. The film sputtering time is 30min, and the film thickness is 1000...

Embodiment 3

[0031] Step 1. Cut the high-purity molybdenum sheet into 2cm×2cm slices, and then ultrasonically clean them in deionized water, acetone and absolute ethanol for 20 minutes, then take it out and blow dry with high-purity nitrogen, and place it in Process in a vacuum drying oven. Finally, stick it on the magnetron sputtering sample tray, install the tellurium target, and prepare for sputtering.

[0032] Step 2: Turn on the magnetron sputtering equipment, vacuum the cavity of the magnetron sputtering equipment, turn on the molecular pump when the resistance unit indicates 3Pa, and turn on the restrictor valve when the composite unit indicates 0.001Pa to open the gas quality For the flow meter, open the target baffle when the composite unit reads 0.2Pa, and when the DC magnetron sputtering power supply is turned on, turn the current adjusting knob to make the voltage read 100V, the current read 10A, and the power 1000W. The film sputtering time is 30 min, and the film thickness is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com