Preparation method of sodium ion battery positive electrode material titanium sodium manganate

A technology for sodium ion batteries and cathode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as material performance not showing significant improvement, preparation process not being fully optimized, and structural instability. Good performance, simple and efficient synthesis process, and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of sodium titanmanganate, a positive electrode material for a sodium ion battery, comprising the following steps:

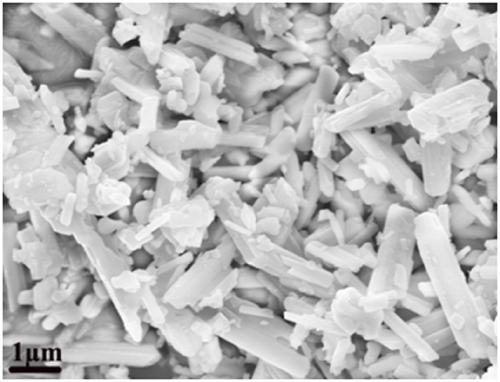

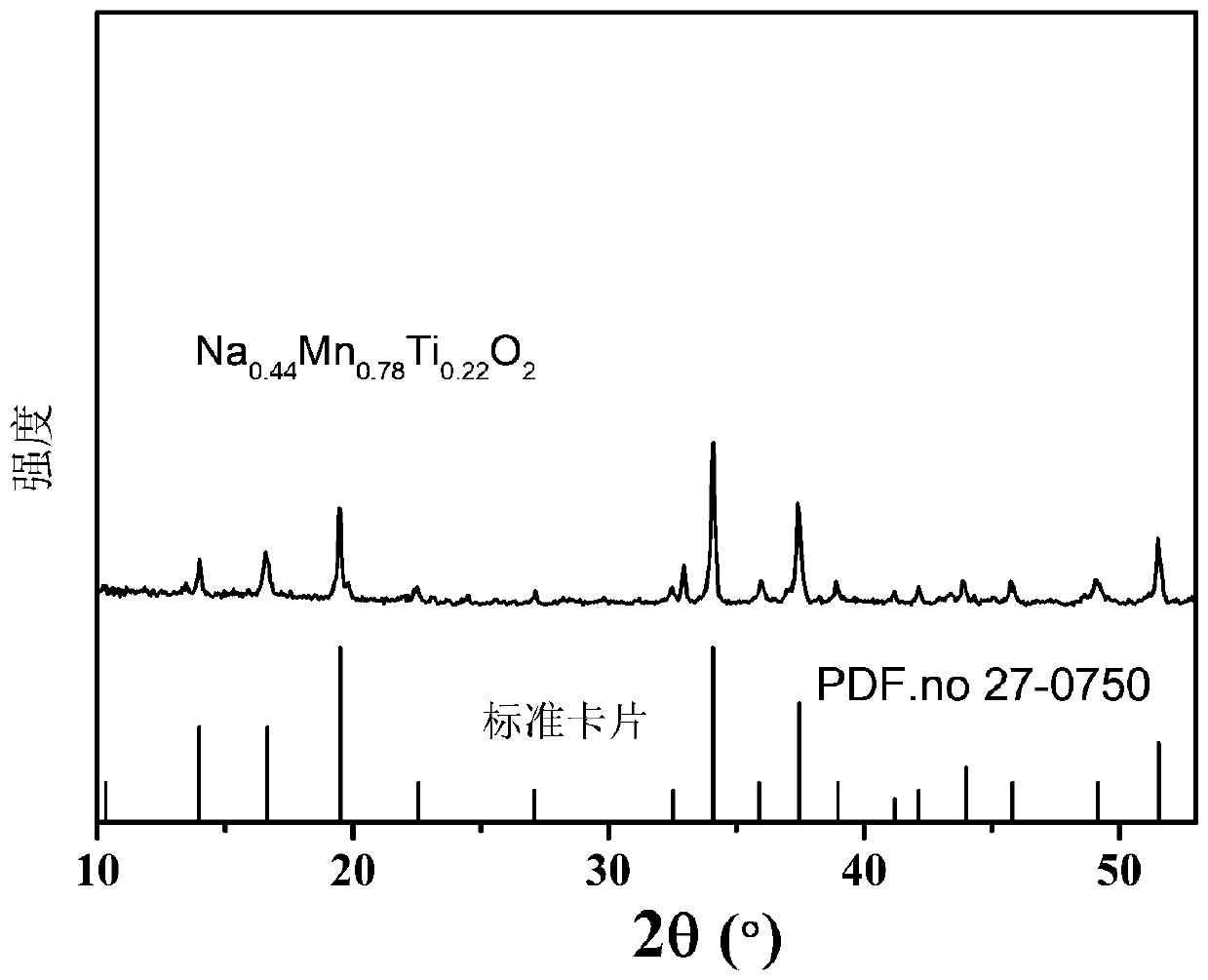

[0036] Add sodium carbonate, manganese acetate, and n-butyl titanate to the pre-prepared oxalic acid solution at a molar ratio of 0.44:0.22:0.78 and mix uniformly to obtain product one; stir the product one at 60°C for 1 hour, then set Evaporate in an air drying oven at 80°C for 12h to make it dry, then grind in a mortar for 30min to obtain product 2, place the product 2 in a muffle furnace and sinter at 900°C for 3 hours in an air atmosphere, then cool to room temperature to get Na 0.44 Ti 0.22 mn 0.78 o 2 ,Such as figure 1 Shown is the SEM surface topography of the material, as image 3 Shown is the XRD spectrum of the material. .

Embodiment 2

[0038] A preparation method of sodium titanmanganate, a positive electrode material for a sodium ion battery, comprising the following steps:

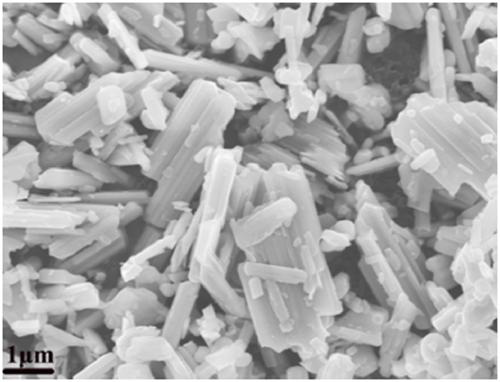

[0039] Add sodium carbonate, manganese acetate, and n-butyl titanate to the pre-prepared oxalic acid solution at a molar ratio of 0.44:0.10:0.90 and mix uniformly to obtain product one; stir the product one at 60°C for 1 hour, then set Evaporate in an air drying oven at 80°C for 12h to make it dry, then grind in a mortar for 30min to obtain product 2, place the product 2 in a muffle furnace and sinter at 900°C for 3 hours in an air atmosphere, then cool to room temperature to get Na 0.44 Ti 0.11 mn 0.89 o 2 ,Such as figure 2 Shown is the SEM surface topography of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com