Preparation method of composite solid electrolyte based on metal organic framework/ionic liquid

A metal-organic framework, solid-state electrolyte technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of poor performance of composite solid-state electrolytes, unable to meet the needs of high-performance solid-state lithium batteries, etc. Effects of interfacial contact, growth inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Dissolve 3.93 g of copper nitrate trihydrate and 2.15 g of trimesic acid in 500 mL of methanol, stir evenly, and after standing at room temperature for 24 hours, centrifuge, wash and dry to obtain HKUST-1 material; After body grinding, place in a vacuum oven at 150 o C further activated to remove the moisture in the channel, and then the activated HKUST-1 material was placed in an argon-filled glove box for storage.

[0028] (2) Weigh 1.00 g LiTFSI dissolved in 5.45 g [EMIM + ][TFSI - ], stirred for 12 hours to obtain a lithium-containing ionic liquid, denoted as Li-IL, and stored in an argon-filled glove box.

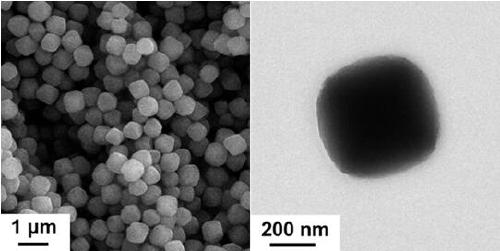

[0029] (3) In an argon-filled glove box, drop 1.80 g Li-IL onto 0.80 g activated HKUST-1 powder drop by drop, and grind continuously so that Li-IL is completely perfused into the pores of HKUST-1 within the road, and on 120 o C was further vacuum-dried for 24 hours to obtain Li-IL@HKUST-1, as figure 1 As shown, the prepared Li-IL@HKUST-1 presents a regu...

Embodiment 2

[0033] (1) Dissolve 3.93 g of copper nitrate trihydrate and 2.15 g of trimesic acid in 500 mL of methanol, stir evenly, and after standing at room temperature for 24 hours, centrifuge, wash and dry to obtain HKUST-1 material; After body grinding, place in a vacuum oven at 150 o C further activated to remove the moisture in the channel, and then the activated HKUST-1 material was placed in an argon-filled glove box for storage.

[0034] (2) Weigh 1.00 g LiTFSI dissolved in 5.45 g [EMIM + ][TFSI - ], stirred for 12 hours to obtain a lithium-containing ionic liquid, denoted as Li-IL, and stored in an argon-filled glove box.

[0035] (3) In an argon-filled glove box, drop 1.80 g Li-IL onto 0.80 g activated HKUST-1 powder drop by drop, and grind continuously so that Li-IL is completely perfused into the pores of HKUST-1 within the road, and on 120 o C was further vacuum-dried for 24 hours to obtain Li-IL@HKUST-1, as figure 1 As shown, the prepared Li-IL@HKUST-1 presents a regu...

Embodiment 3

[0039] (1) Dissolve 3.93 g of copper nitrate trihydrate and 2.15 g of trimesic acid in 500 mL of methanol, stir evenly, and after standing at room temperature for 24 hours, centrifuge, wash and dry to obtain HKUST-1 material; After body grinding, place in a vacuum oven at 150 o C further activated to remove the moisture in the channel, and then the activated HKUST-1 material was placed in an argon-filled glove box for storage.

[0040] (2) Weigh 1.00 g LiTFSI dissolved in 5.45 g [EMIM + ][TFSI - ], stirred for 12 hours to obtain a lithium-containing ionic liquid, denoted as Li-IL, and stored in an argon-filled glove box.

[0041] (3) In an argon-filled glove box, drop 1.80 g Li-IL onto 0.80 g activated HKUST-1 powder drop by drop, and grind continuously so that Li-IL is completely perfused into the pores of HKUST-1 within the road, and on 120 o C was further vacuum-dried for 24 hours to obtain Li-IL@HKUST-1, as figure 1 As shown, the prepared Li-IL@HKUST-1 presents a regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com