Roller type continuous cold roll forming method for U-shaped steel sheet pile

A cold-formed and steel sheet pile technology, applied in the field of sheet pile forming and processing, can solve the problems of sheet springback angle, high equipment cost and precision requirements, rough surface at the bend, etc., to avoid rigid contact and save roller frames. The effect of reducing the number of passes and reducing the wear of the roll die

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

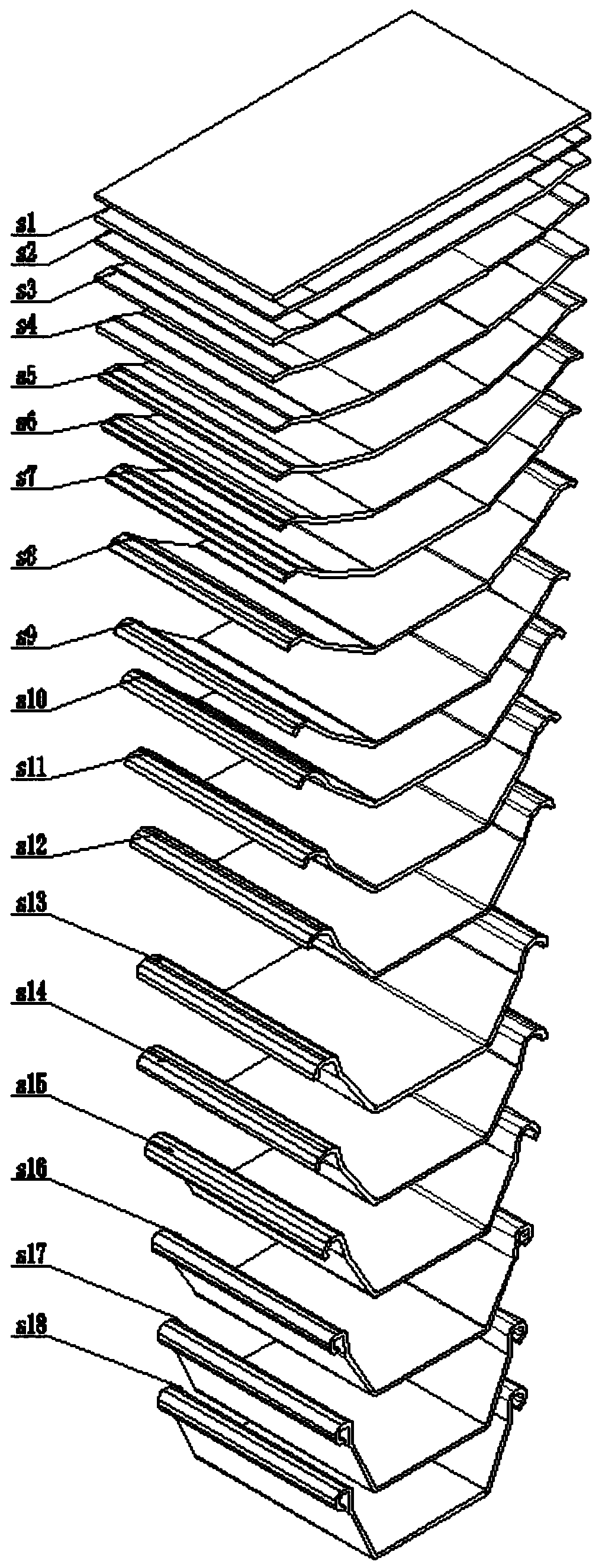

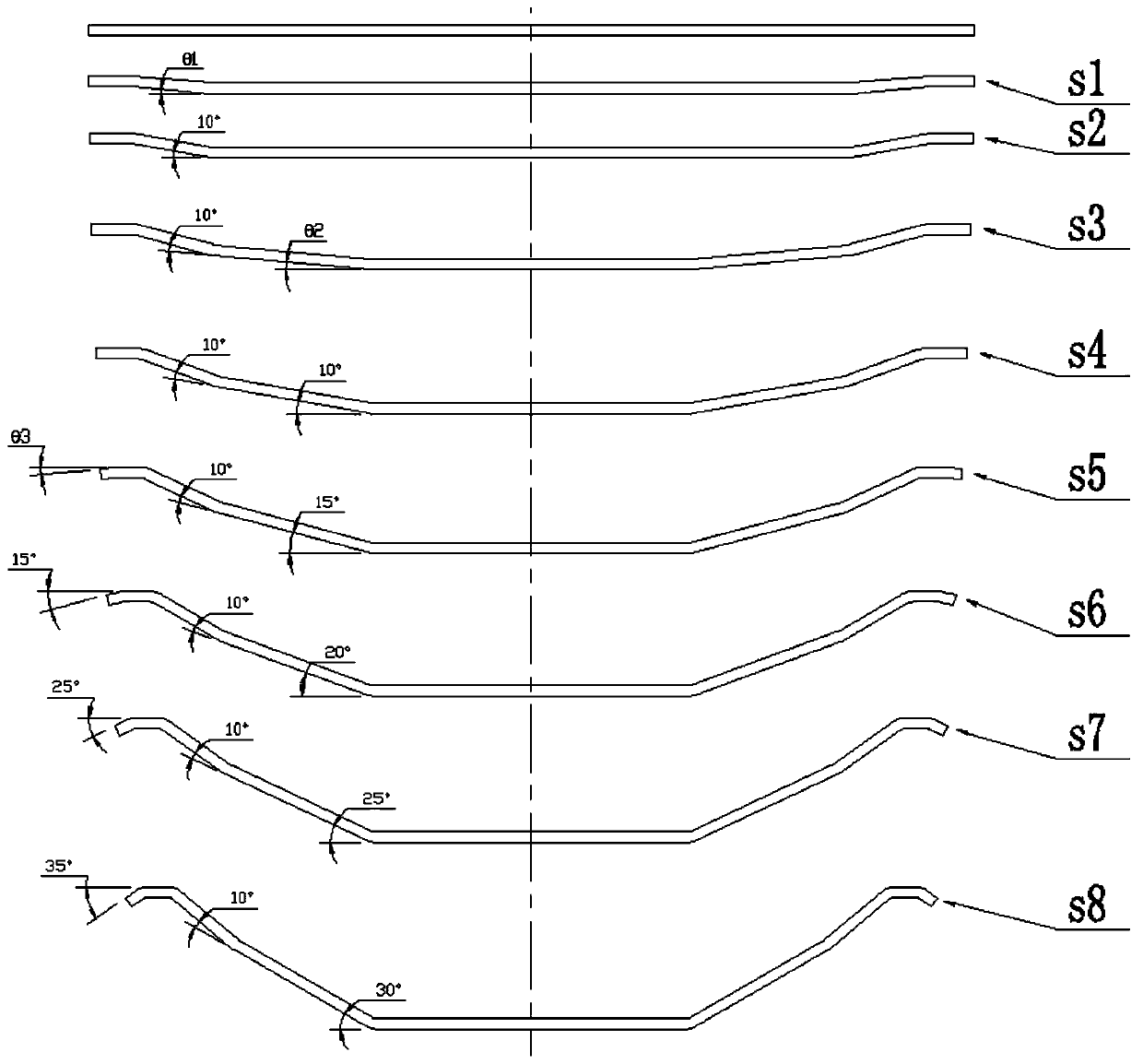

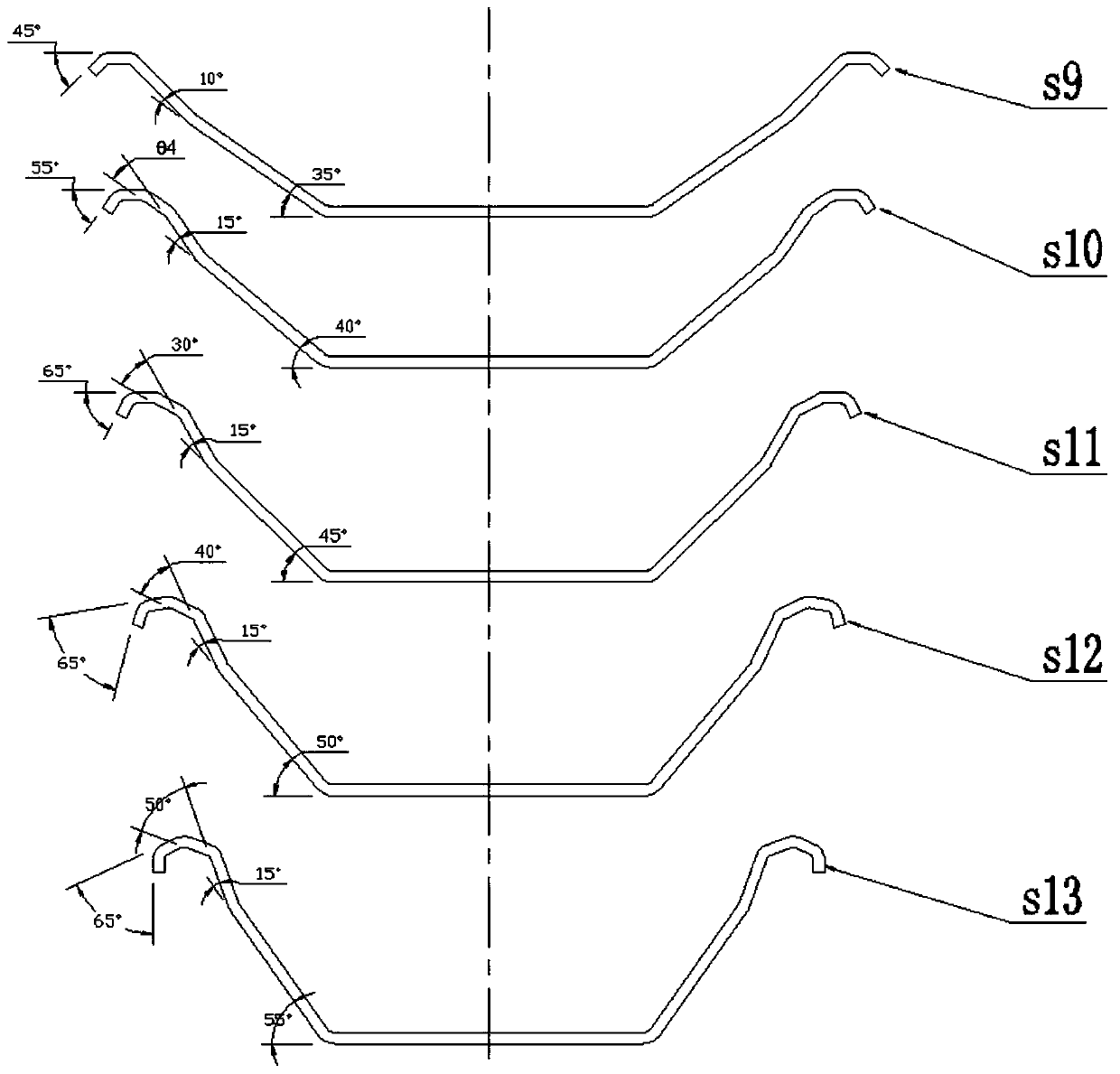

[0038] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0039] A roll-type continuous cold-bending forming method for U-shaped steel sheet piles, wherein the forming method is as follows:

[0040] S1: Straighten the strip just after passing through the decoiler, place the flattened strip on the roller cold bending forming machine, and enter the first symmetrical upper and lower paired roller mold, so that the two sides of the steel strip are bent symmetrically to the horizontal line The shape of θ1, θ1 is less than or equal to 5°;

[0041] S2: The strip just advances smoothly into the second pair of symmetrical roller molds, so that the strip passes through the first symmetrical bend on both sides of step S1, and forms a shape with an incremental angle of 5° with the horizontal line;

[0042] S3: The strip just moves forward and smoothly enters the third pair of symmetrical roller molds, so that...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap