Packaging structure for regulating release rate of chlorine dioxide

A chlorine dioxide release rate technology, which is applied in packaging, transportation and packaging, and rot-proof containers, can solve the problems of potential safety hazards and unstable release rates of active ingredients in use, and achieve balanced release rates and low production costs. control and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

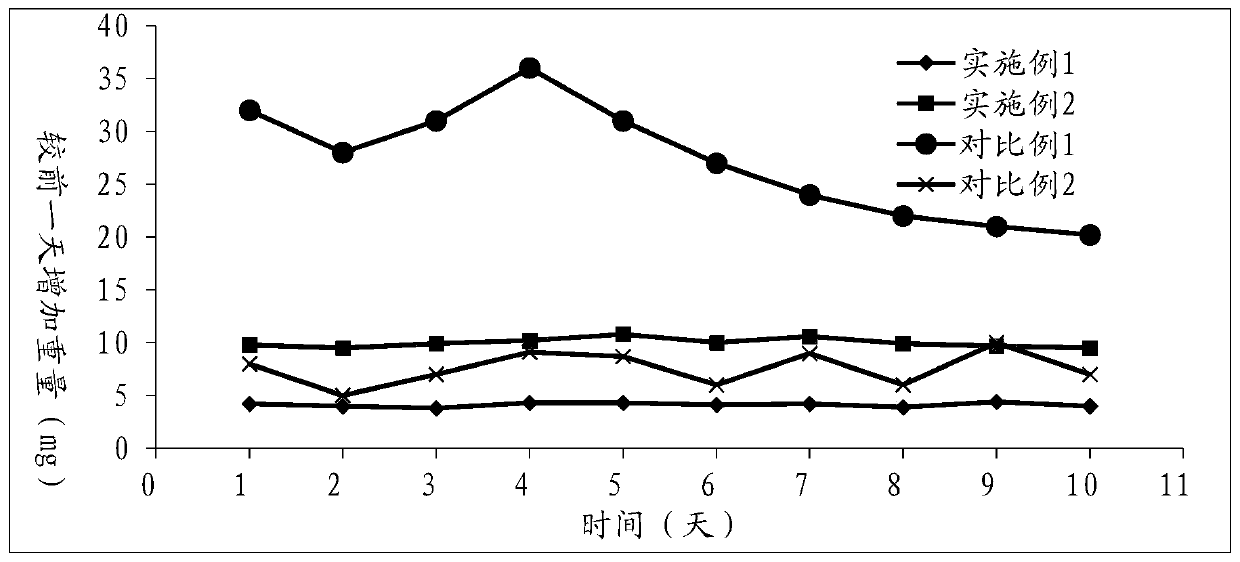

Embodiment 1

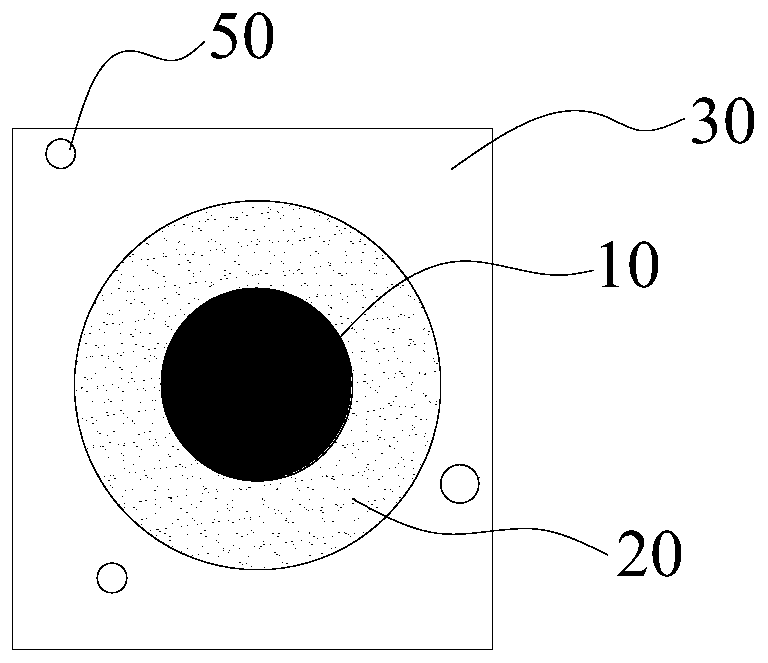

[0067] A packaging structure for regulating the release rate of chlorine dioxide, including an activation slow-release layer, a protective control-release layer and a termination barrier layer.

[0068] The activated slow-release layer adopts a composite breathable film, the structural material is: paper / polyethylene fiber / polyethylene, and the weight is 80g / m 2 , water vapor transmission rate (according to YY / T 0471.2-2014, temperature 37 ℃ ± 1 ℃, relative humidity 2 ·24h), white, opaque. The bag size is 50mm×80mm.

[0069] The protective and controlled release layer adopts a composite aluminum film. The material of the composite aluminum film includes biaxially stretched polypropylene 18 / aluminum 7 / transparent PE140, and the weight before opening is 120g / m 2 , water vapor transmission rate (according to GB / T 1037-1988, temperature 38 ℃ ± 0.6 ℃, relative humidity 90% ± 2%) ≤ 10g / (m 2 ·24h), opaque. Dimensions after bagging: 70mm×110mm, there are 15 round holes with a diame...

Embodiment 2

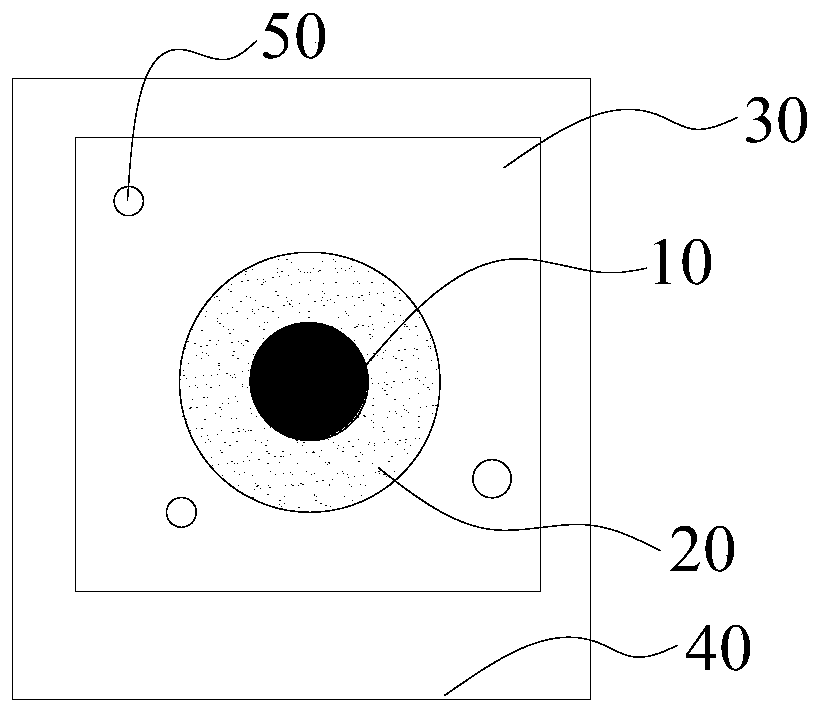

[0072] A packaging structure for regulating the release rate of chlorine dioxide, including an activation slow-release layer, a protective control-release layer and a termination barrier layer.

[0073] The activated slow-release layer adopts a composite breathable film, the structural material is: polypropylene non-woven fabric / polyethylene, the weight is 100g / ㎡, the water vapor transmission rate (according to YY / T 0471.2-2014, the temperature is 37°C±1°C, relative Humidity 2 ·24h), white, opaque. The bag size is 50mm×80mm.

[0074] The protective and controlled release layer adopts composite aluminum film, and the structural material is biaxially stretched polypropylene 18 / aluminum 7 / transparent PE140, and the weight before opening is 120g / m 2 , water vapor transmission rate (according to GB / T 1037-1988, temperature 38 ℃ ± 0.6 ℃, relative humidity 90% ± 2%) ≤ 10g / (m 2 ·24h), opaque. Dimensions after forming the bag: 70mm×110mm, there are 18 round holes with a diameter of ...

Embodiment 3

[0077] A packaging structure for regulating the release rate of chlorine dioxide, including an activation slow-release layer, a protective control-release layer and a termination barrier layer.

[0078] The activated slow-release layer adopts a composite breathable film, the structural material is: polyester / polyethylene, the weight is 50g / m 2 , water vapor transmission rate (according to YY / T 0471.2-2014, temperature 37 ℃ ± 1 ℃, relative humidity 2 ·24h), white, opaque. The bag size is 50mm×80mm.

[0079] The protective and controlled release layer adopts a film-coated cardboard bag, and the weight before opening is 300g / m 2 ,opaque. Dimensions after forming the bag: 70mm×110mm, 18 round holes with a diameter of 3mm on the bag, and the opening area is 226mm 2 .

[0080] The sealing termination layer is made of composite aluminum film, and the structural material is biaxially stretched polypropylene 18 / aluminum 7 / transparent PE140, and the weight is 120g / m 2 , water vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com