Lanthanide series metal-organic framework material with excellent second harmonic performance and preparation method thereof

A second harmonic and lanthanide metal technology, applied in the field of lanthanide metal-organic framework materials and their preparation, can solve problems such as lack of theory and achieve excellent second harmonic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

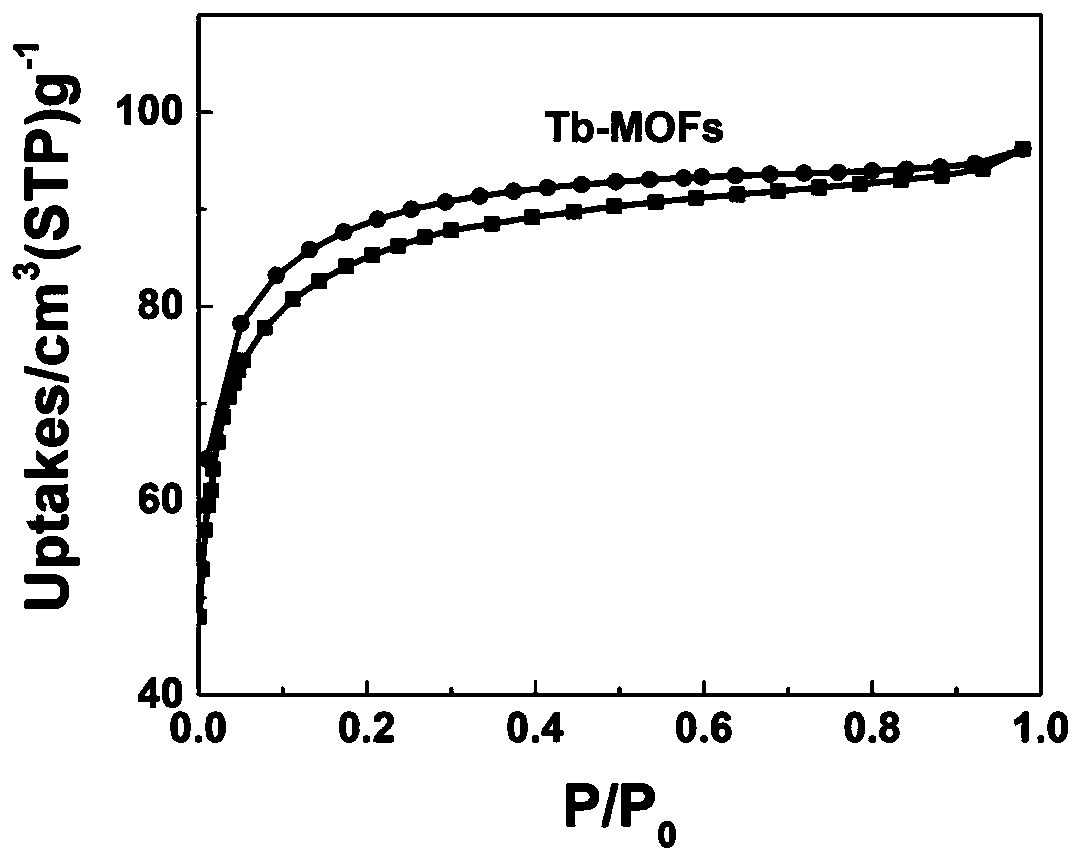

[0029] Utilizing terbium nitrate and hexyl[4-(carboxyphenyl)carbonyl]-3-oxane, a metal-organic framework material was synthesized by a solvothermal method. The specific synthetic route is as follows:

[0030] Dissolve 0.1 mmol of terbium nitrate and 0.1 mmol of hexyl[4-(carboxyphenyl)carbonyl]-3-oxane in 7 mL of DMF and 1 mL of H 2 O mixed solvent, then add 1mL HNO 3 aqueous solution (1M). The solution was packaged in a 20mL polytetrafluoroethylene reactor, and placed in an oven at 160°C for 72 hours. After cooling to room temperature and washing with DMF three times, a colorless needle-like metal-organic framework material Tb was obtained. 2 L(DMF) 2 ·(H 2 O) 5 (DMF) 3 .

Embodiment 2

[0032] Utilizing lanthanum nitrate and hexyl[4-(carboxyphenyl)carbonyl]-3-oxane, a metal-organic framework material was synthesized by a solvothermal method. The specific synthetic route is as follows:

[0033] Dissolve 0.1 mmol of lanthanum nitrate and 0.1 mmol of hexyl[4-(carboxyphenyl)carbonyl]-3-oxane in 7 mL of DMF and 1 mL of H 2 O mixed solvent, then add 1mL HNO 3 aqueous solution (1M). The solution was packaged in a 20mL polytetrafluoroethylene reactor, and placed in an oven at 160°C for 72 hours. After cooling to room temperature and washing 3 times with DMF, a colorless needle-like metal-organic framework La 2 L·(H 2 O) 5 (DMF) 5 .

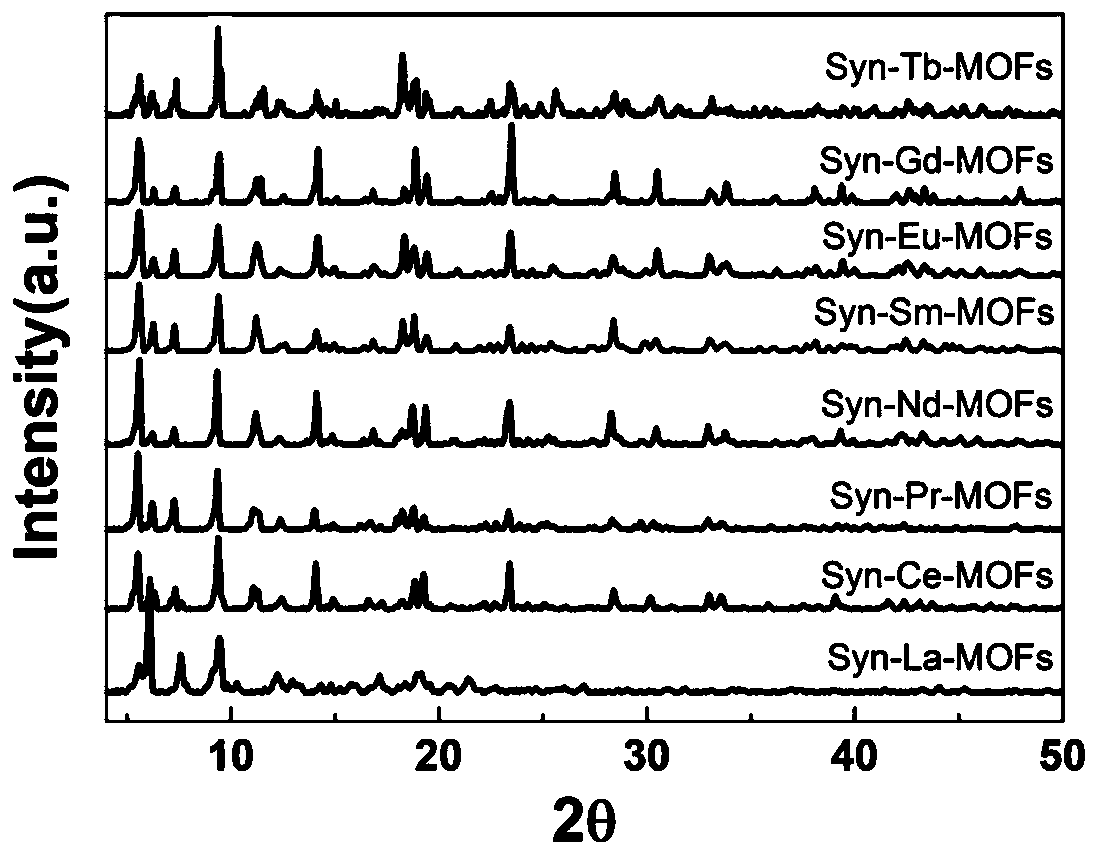

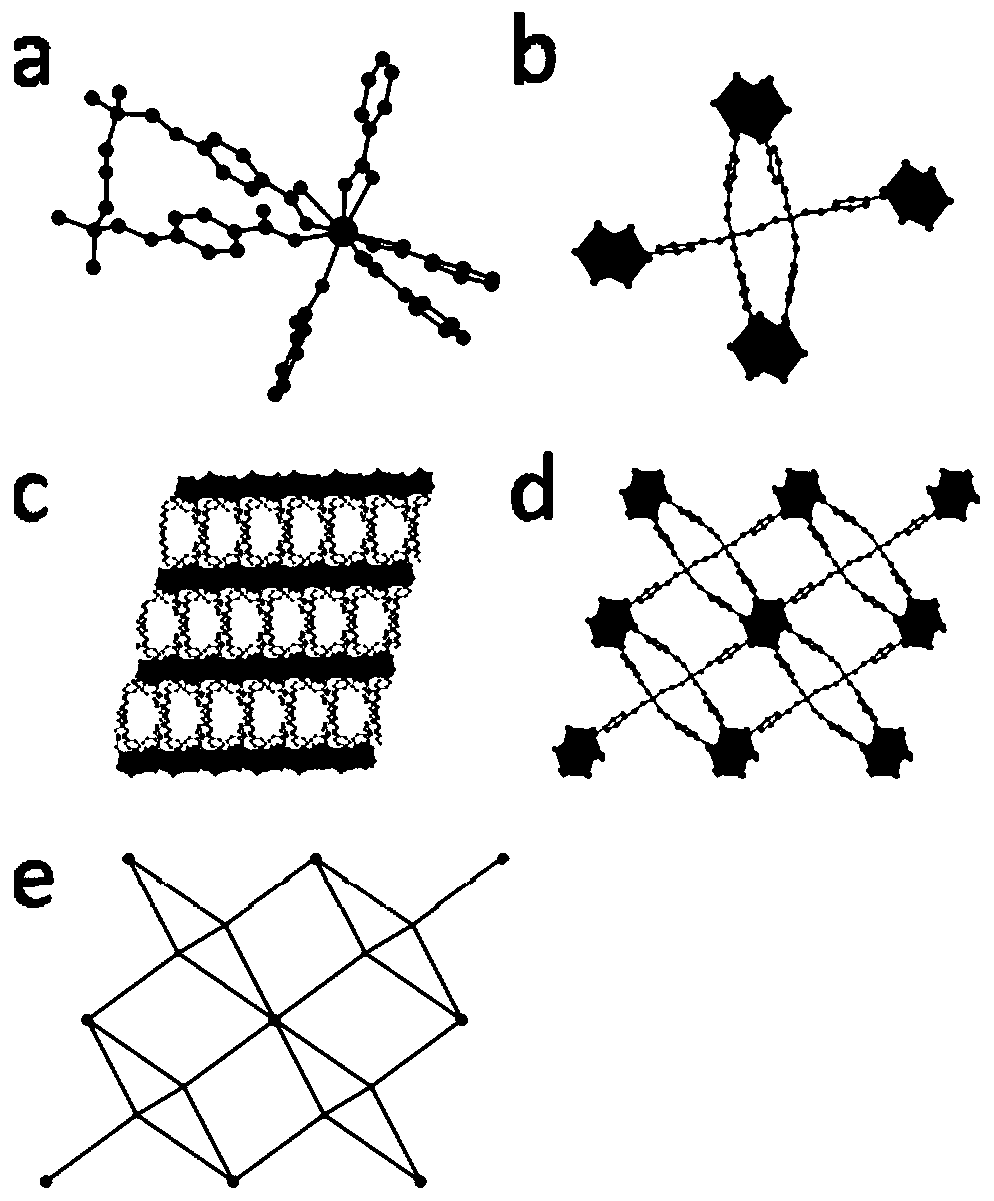

[0034] Using the preparation method of the present invention, the corresponding MOFs materials were synthesized for eight kinds of lanthanide metals. It can be clearly seen from powder X-ray diffraction (PXRD) that La-Tb-MOFs are isomorphic. ( figure 1 ). To verify the differences in crystal structure, single crystal resolution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com