Formula and preparation method of pungent-smell-free acrylonitrile-butadiene-styrene foamed plastic

A pungent odor and foaming plastic technology, applied in the field of plastic formulations, can solve problems such as exothermic action of AC foaming agent exacerbating odor, physical and mental health and working status of injection molding operators, and affecting product quality feedback, etc., to achieve strong competition force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The acrylonitrile-butadiene-styrene foamed plastic formula without irritating smell is composed of the following components by weight percentage:

[0055] Acrylonitrile-butadiene-styrene 95%;

[0056] AC foaming agent 3%;

[0057] Diffusion agent EB-FF 1%;

[0058] Antioxidant 1010 0.3%;

[0059] Antioxidant 168 0.2%; and,

[0060] Purified biological enzyme enzyme (pumpkin vine biological enzyme enzyme) 0.5%; the enzyme product made from pumpkin vine as raw material is commercially available, such as the 601 type enzyme produced by Shanghai Qianbao Fine Chemical Co., Ltd.;

[0061] The sum of the above ingredients is 100%.

[0062] Preparation:

[0063] Step S1, weigh according to the above-mentioned foamed plastic formula, and put acrylonitrile-butadiene-styrene, diffusing agent EB-FF, antioxidant 1010, antioxidant 168 and purified biological enzymes in a mixer for mixing (AC blowing agent is not added here), forming a mixture;

[0064] Step S2, mixing the mixt...

Embodiment 2

[0071] The acrylonitrile-butadiene-styrene foamed plastic formula without irritating smell is composed of the following components by weight percentage:

[0072] Acrylonitrile-butadiene-styrene 96%;

[0073] AC foaming agent 2%;

[0074] Diffusion agent EB-FF 1%;

[0075] Antioxidant 1010 0.25%;

[0076]Antioxidant 168 0.25%; and,

[0077] Purified bio-enzyme (pumpkin vine bio-enzyme) 0.5%;

[0078] The sum of the above ingredients is 100%.

[0079] The preparation method is the same as in Example 1.

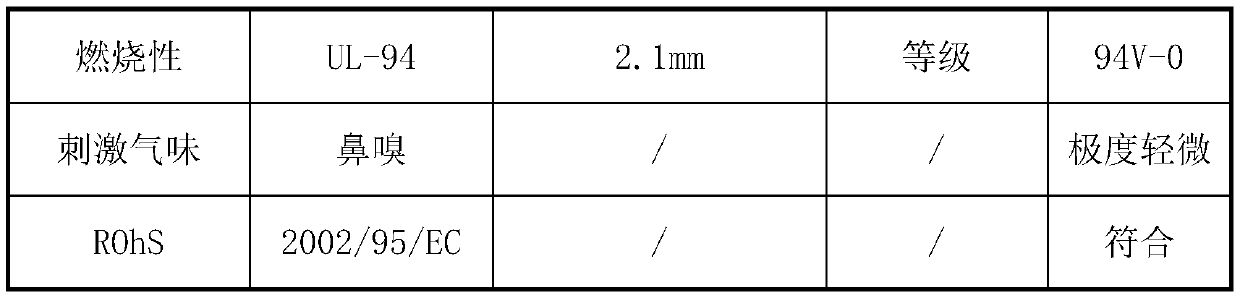

[0080] Performance characteristics: irritating odor, extremely slight.

Embodiment 3

[0082] The acrylonitrile-butadiene-styrene foamed plastic formula without irritating smell is composed of the following components by weight percentage:

[0083] Acrylonitrile-butadiene-styrene 90.5%;

[0084] AC foaming agent 5%;

[0085] Diffusion agent EB-FF 3%;

[0086] Antioxidant 1010 0.5%;

[0087] Antioxidant 168 0.5%; and,

[0088] Purified bio-enzyme (pumpkin vine bio-enzyme) 0.5%;

[0089] The sum of the above ingredients is 100%.

[0090] The preparation method is the same as in Example 1.

[0091] Performance characteristics: irritating odor, slight.

[0092] Thus, embodiment 1 is better than embodiment 2, and embodiment 2 is better than embodiment 3 again. The reason is that the weight percent sum of antioxidant 1010 and antioxidant 168 in embodiments 1 and 2 is equal to the weight percent of purified biological enzyme ferment, and the antioxidant 1010 and antioxidant 168 of embodiment 3 The sum of the weight percentages is far greater than the weight per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com