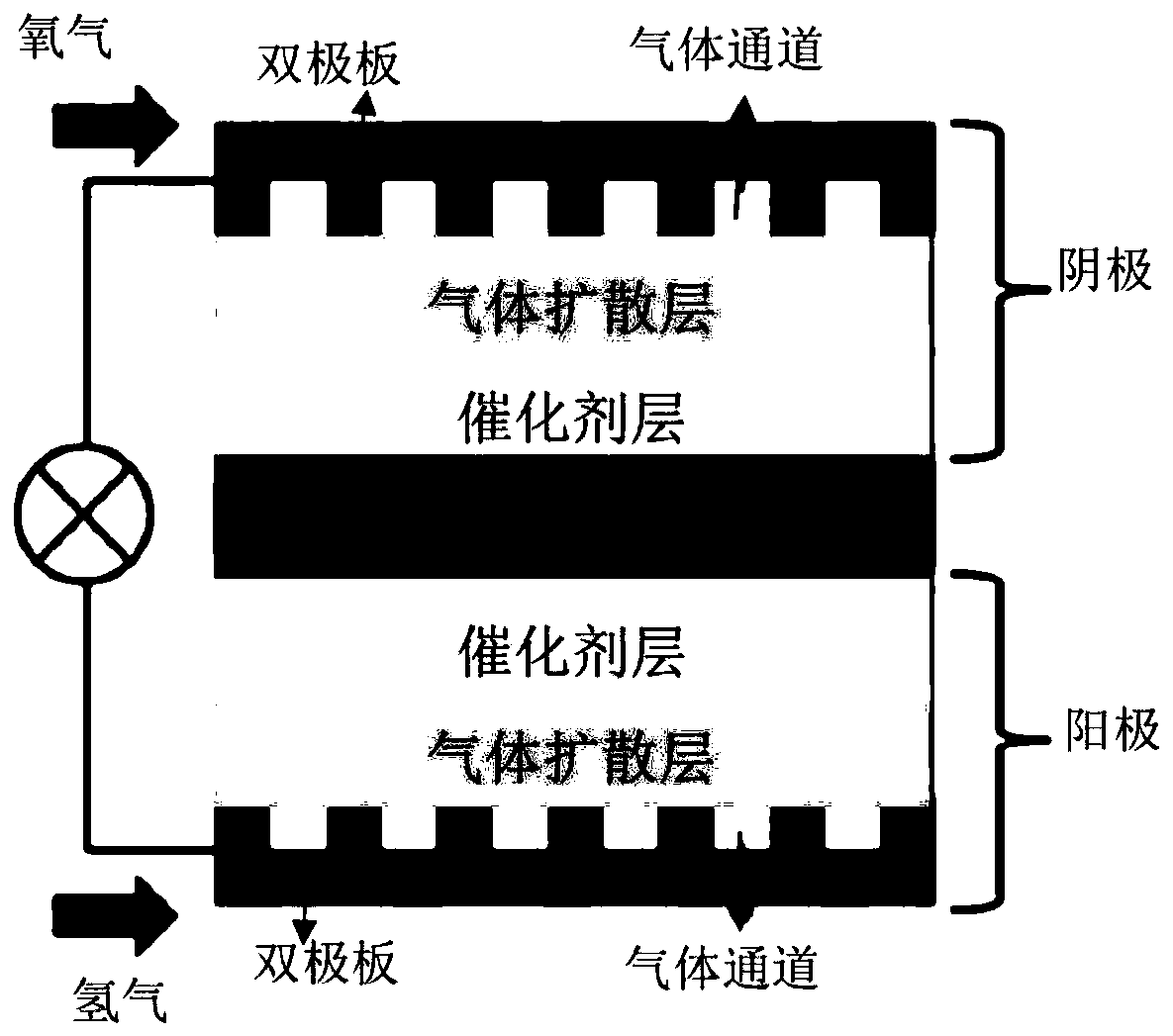

Gas diffusion layer of fuel cell and preparation method thereof and fuel cell

A gas diffusion layer and fuel cell technology, which is used in fuel cells, fuel cell additives, battery electrodes, etc., can solve the problems of poor hydrophobicity of the diffusion layer, etc., to improve the stability of current operation, easy operation, and improve output performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The carbon paper of Example 1 was purchased from Japan Toray’s model TGP-H-060, and the carbon paper of Example 2 was purchased from Japan’s Toray Model TGP-H-030.

[0058] PTFE solution was purchased from Chemours, USA, with a mass fraction of 60%.

[0059] Vulcan-xc72 was purchased from Cabot Cabot in the United States.

[0060] Ethylene glycol was purchased from Sinopharm Chemical Reagent Co., Ltd., analytically pure.

[0061] Tween 80 was purchased from sigma-Aldrich.

[0062] The Pt / C catalyst was purchased from Johnson Matthey, model HiSPEC 9100, 55.5-58.5% Pt.

[0063] The proton exchange membrane was purchased from Chemours, model NC700.

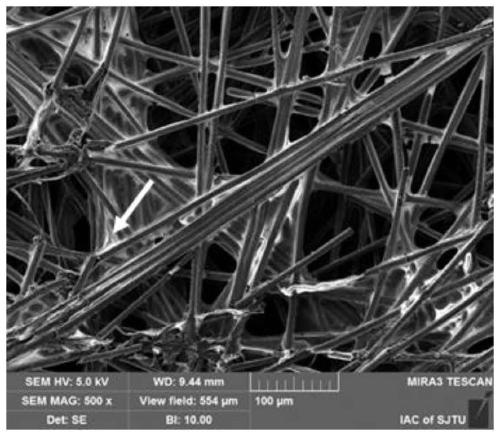

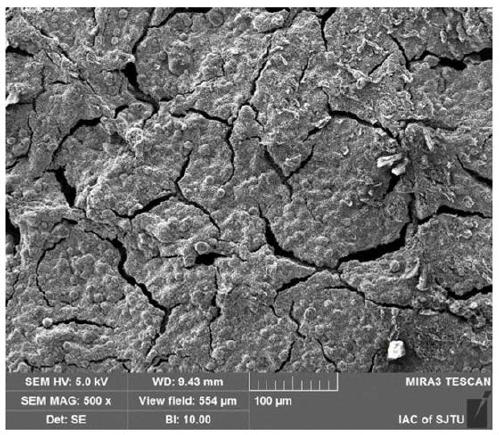

[0064] Effect The type of scanning electron microscope used in the embodiment is Sirion 200 from FEI Company of the United States; the test instrument for contact angle is DSA100 German optical contact angle measuring instrument.

[0065] Example 1

[0066] Preparation of the gas diffusion layer:

[0067] 1. Place carbon...

Embodiment 2

[0071] Except following conditions, other conditions are all identical with embodiment 1:

[0072] 1. The thickness of the carbon base material is 0.11mm, and the model of the carbon base material is TGP-H-030;

[0073] When coating, the temperature of the heating plate is 100°C;

[0074] The dosage of PTFE solution is 0.06mL / cm 2 carbon base material;

[0075] The concentration of PTFE solution is 8%;

[0076] The hydrophobic curing temperature is 280°C; the curing temperature is 90s;

[0077] After curing, the weight of PTFE in the hydrophobic carbon base material is 12.7%;

[0078] 2. In the slurry, the mass ratio of conductive carbon powder, dispersant, hydrophobic binder and emulsifier is 1:12:0.2:0.1;

[0079] The emulsifier is Triton x-100;

[0080] Conductive carbon powder is a mixture of graphite powder and conductive carbon black, the masses are 4g and 12g respectively; the conductive carbon black is EC600J;

[0081] The dispersant is a mixture of 192g of wate...

Embodiment 3

[0088] Except following conditions, other conditions are all identical with embodiment 1:

[0089] 1. The carbon base material is carbon cloth;

[0090] When coating, the temperature of the heating plate is 120°C;

[0091] The dosage of PTFE solution is 0.04mL / cm 2 carbon base material;

[0092] The concentration of PTFE solution is 33%;

[0093] The hydrophobic curing temperature is 365°C; the curing temperature is 60s;

[0094] After curing, the weight of PTFE in the hydrophobic carbon base material is 16%;

[0095] 2. In the slurry, the mass ratio of conductive carbon powder, dispersant, hydrophobic binder and emulsifier is 1:20:4:2;

[0096] The emulsifier is Triton x-100;

[0097] Conductive carbon powder is a mixture of conductive carbon black and carbon nanotubes, with a mass of 16g and 2g respectively;

[0098] The dispersant is a mixture of 360g water and isopropanol, and the mass ratio of water to isopropanol is 2:4;

[0099] The stirring speed is 200rpm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com