An integrated bionic liquid-absorbing core for loop heat pipe, preparation method and application

A loop heat pipe, integrated technology, used in lighting and heating equipment, additive manufacturing, indirect heat exchangers, etc., can solve the problems of contradictory capillary suction performance and permeability, and poor anti-gravity operation performance of loop heat pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

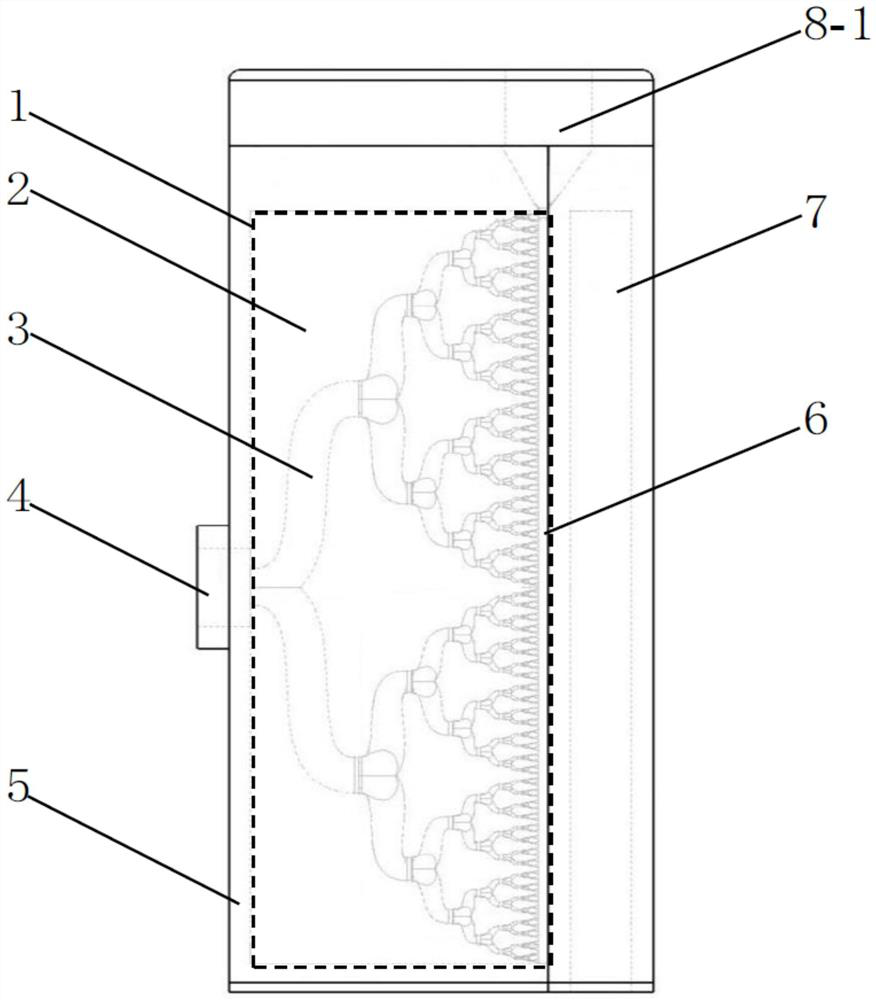

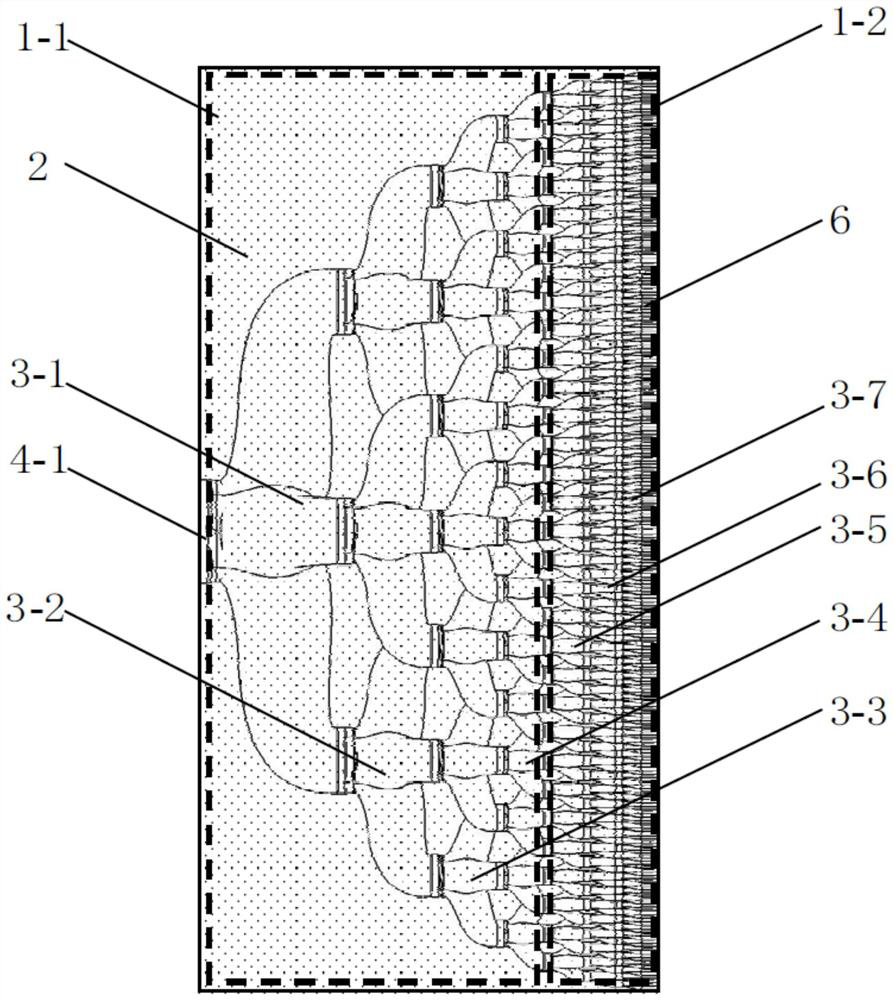

[0029] Such as figure 2 , an integrated bionic liquid-absorbing wick 1 for a loop heat pipe according to this embodiment, comprising a porous structure substrate 2, a liquid compensation chamber 1-1 and a capillary suction channel 1-2;

[0030] The liquid compensation chamber 1-1 and the capillary suction channel 1-2 are arranged in the base body 2, the liquid compensation chamber 1-1 is provided with a liquid inlet 4-1, and is connected to the capillary suction channel 1 at the downstream port of the liquid compensation chamber. -2 connected, the downstream port of the capillary suction channel 1-2 is a steam outlet;

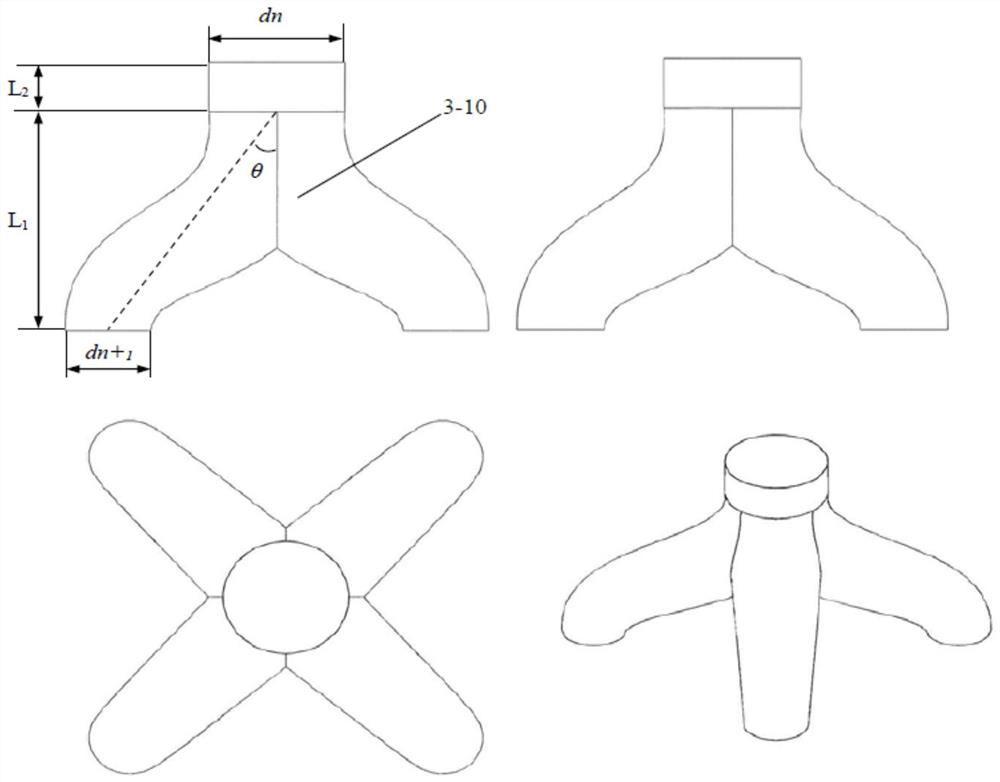

[0031] In this embodiment, the liquid compensation chamber 1-1 and the capillary suction channel 1-2 are arranged in multiple stages, with the channel where the liquid inlet 4-1 is located as the first-stage channel 3-1, forming a tree branched along the liquid flow direction. A network-like multi-level bionic channel 3, the first to fourth-level channels (3-...

Embodiment 2

[0036] This embodiment provides a method for preparing an integrated bionic liquid-absorbing core 1, and the porous structure matrix 2 is manufactured by combining powder sintering technology and 3D printing technology. First, design the parameters of the multi-level bionic channel 3 according to the requirements, use alumina powder as the raw material, and use selective laser sintering 3D printing technology to manufacture the solid structure of the multi-level bionic channel 3, and use this as the core to put it into the powder sintering mold In the process, red copper powder is filled, the powder sintering mold is put into a sintering furnace together with the core of the multi-level bionic channel 3 for sintering, and finally the multi-level bionic channel 3 is dissolved with a strong alkali solution of sodium hydroxide to obtain a multi-level bionic channel 3 The porous structure of the matrix 2.

Embodiment 3

[0038] This embodiment provides a method for preparing an integrated bionic liquid-absorbing core 1 , using selective laser sintering 3D printing technology to manufacture the porous structure matrix 2 of the liquid-absorbing core 1 . Design the overall model of the integrated liquid-absorbing core 1 with multi-level bionic channels 3, and import the model into the 3D printer, select copper powder as the raw material, and adjust the laser power, scanning time and scanning time by selecting the process parameters of 3D printing. The path melts the surface of the powder, the part of the powder and the surface of the powder are connected to form a sintering neck, and micro pores are formed between multiple powders. Through this method, a porous structure matrix 2 with a pore structure can be formed, and the multi-level biomimetic channel 3 inside it can be obtained by automatically forming a scanning pattern by a 3D printer according to the model structure. This embodiment is dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com