An efficient and recyclable solid-liquid separation method for industrial wastewater

A technology for solid-liquid separation and industrial wastewater, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as high operating costs, large wastewater volume, increased conductivity and salt content, etc., to improve efficiency, Effects that improve effectiveness and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate those skilled in the art understand, in conjunction with the accompanying drawings of the embodiments will now structure of the present invention will be further described in detail:

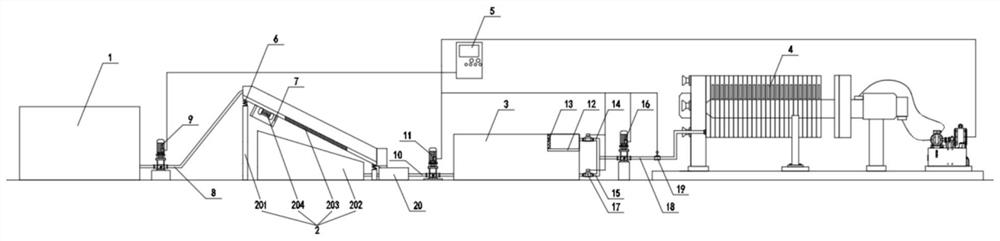

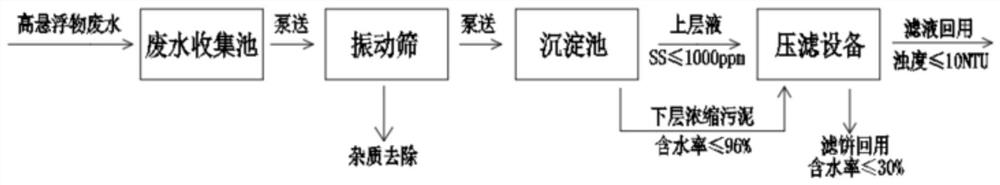

[0027] refer to figure 1 A recyclable industrial waste water highly efficient solid-liquid separation apparatus comprising a waste water collection tank arranged in the order of 1, 2 shaker, the sedimentation tank 3, pressure filtration device 4 and the controller 5 is electrically (electric in this embodiment the controller 5 programmable encoder PLC), said shaker comprising a chassis 2 and fastening means 201 to the sump 201 below the rack 202, the upper rack 201 through the buffer spring 6 is attached to the respective inclined deck 203, the the top deck 203 downwardly with respective fixed vibration motor 204, the motor 204 of the periphery of the vibration plate is covered with a cover 7, with many appropriate sieve mesh 203 below the cover plate 7; the the top dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com