Method for removing uranium in enriched ryegrass degradation raffinate by microorganisms under anaerobic condition

An anaerobic condition, ryegrass technology, applied in anaerobic digestion treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as release into the environment, ecological pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

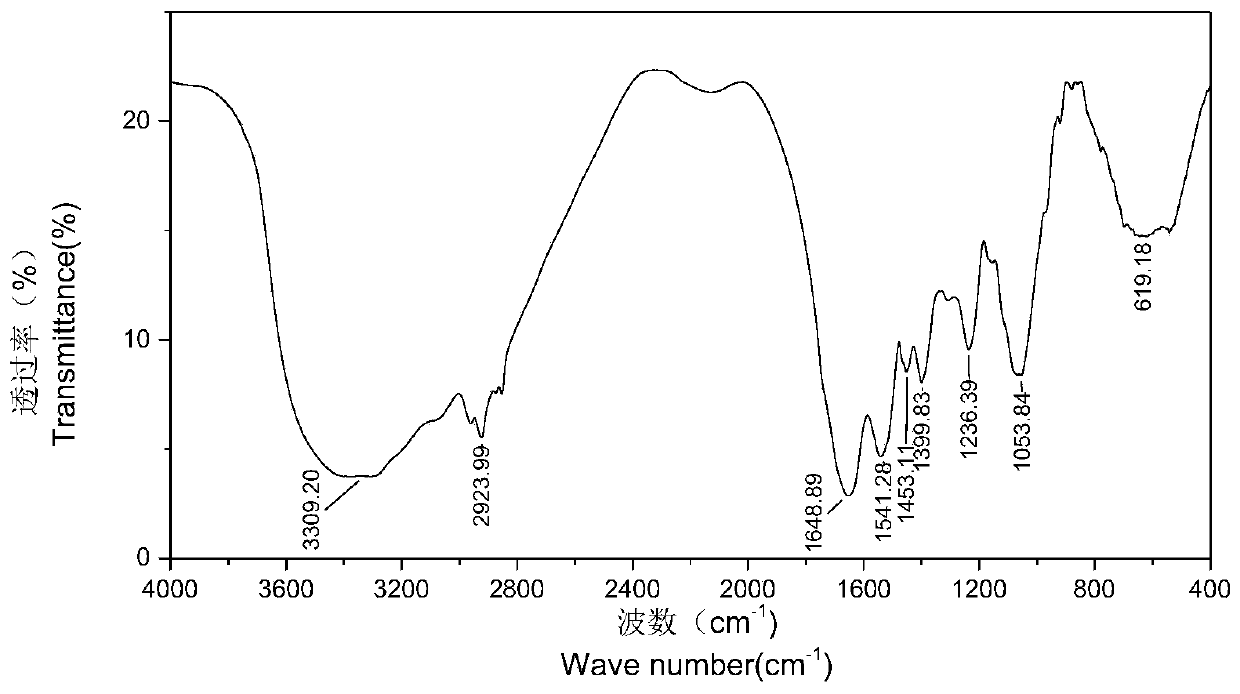

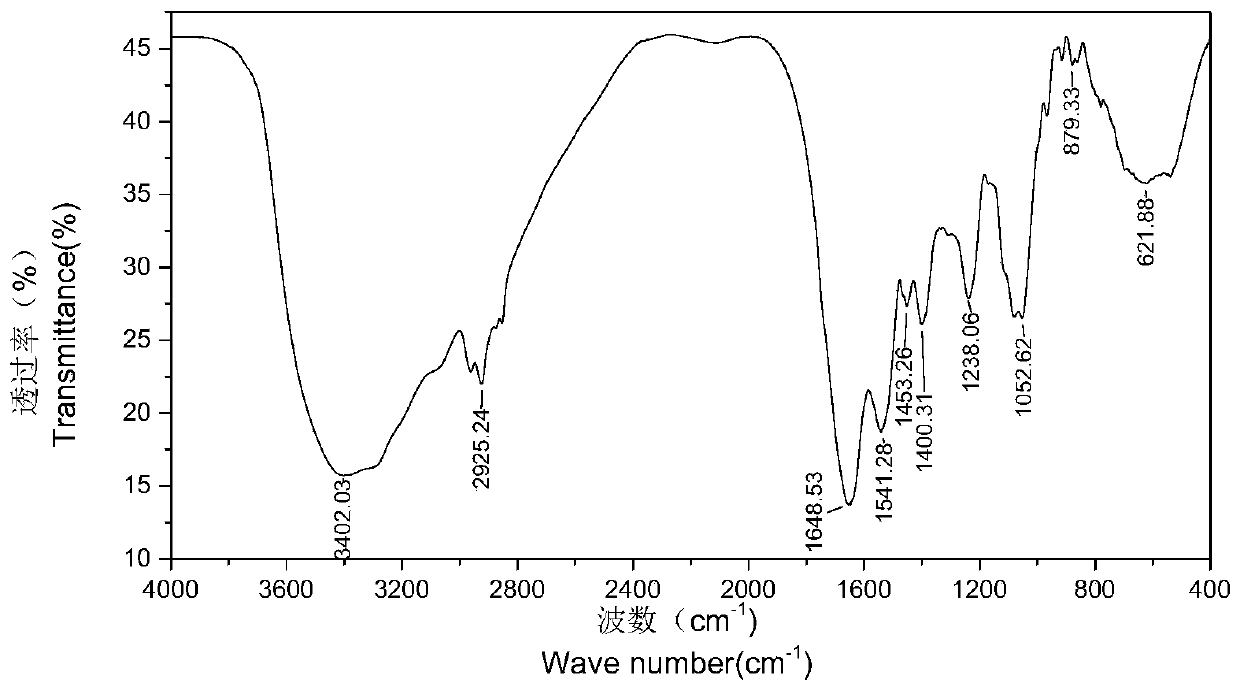

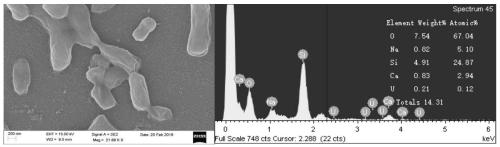

Image

Examples

Embodiment 1

[0027] A method for removing uranium in enriched ryegrass degradation residue by microorganisms under anaerobic conditions, comprising the following steps:

[0028] Step 1: Add 100 mL of enriched ryegrass degradation residue, sodium lactate, anthraquinone-2-sulfonate and inorganic salt medium into the culture container, then inoculate Shewanella putrefaciens, and pass pure nitrogen into the culture container for 5 minutes. And place the culture container in an anaerobic incubator, culture at 30°C for 48 hours, and then centrifuge at 5000rpm for 10 minutes; the anaerobic incubator is replaced with pure nitrogen three times before use; the sodium lactate is degraded in the enriched ryegrass The concentration in the raffinate is 20mmol·L -1 ; The concentration of the anthraquinone-2-sulfonate in enriched ryegrass degradation raffinate is 2mmol L -1 ; The addition of the inorganic salt medium is 1 time of the volume of the enriched ryegrass degradation raffinate; the inoculation ...

Embodiment 2

[0031] A method for removing uranium in enriched ryegrass degradation residue by microorganisms under anaerobic conditions, comprising the following steps:

[0032] Step 1: Add 100 mL of enriched ryegrass degradation residue, sodium lactate, anthraquinone-2-sulfonate and inorganic salt medium into the culture container, then inoculate Shewanella putrefaciens, and pass pure nitrogen into the culture container for 5 minutes. And place the culture container in an anaerobic incubator, culture at 30°C for 48 hours, and then centrifuge at 5000rpm for 10 minutes; the anaerobic incubator is replaced with pure nitrogen three times before use; the sodium lactate is degraded in the enriched ryegrass The concentration in the raffinate is 20mmol·L -1 ; The concentration of the anthraquinone-2-sulfonate in enriched ryegrass degradation raffinate is 2mmol L -1 ; The addition of the inorganic salt medium is 1 time of the volume of the enriched ryegrass degradation raffinate; the inoculation ...

Embodiment 3

[0035] A method for removing uranium in enriched ryegrass degradation residue by microorganisms under anaerobic conditions, comprising the following steps:

[0036] Step 1: Add 100 mL of enriched ryegrass degradation residue, sodium formate, anthraquinone-2-sulfonate and inorganic salt medium into the culture container, then inoculate Shewanella putrefaciens, and pass pure nitrogen into the culture container for 5 minutes. And place the culture container in an anaerobic incubator, culture at 30°C for 48h, and then centrifuge at 5000rpm for 10min; the anaerobic incubator is replaced with pure nitrogen three times before use; the sodium formate is degraded in the enriched ryegrass The concentration in the raffinate is 20mmol·L -1 ; The concentration of the anthraquinone-2-sulfonate in enriched ryegrass degradation raffinate is 3mmol L -1 ; The addition of the inorganic salt medium is 0.5 times the volume of the enriched ryegrass degradation raffinate; the inoculum size of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com