Method and device for preparing heptafluoroisobutyronitrile

A technology for heptafluoroisobutyronitrile and methyl heptafluoroisobutyrate, which is applied in the field of devices for synthesizing heptafluoroisobutyronitrile, can solve the problems of difficult operation, complicated equipment, long process and the like, achieves simplified operation process, reduced The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

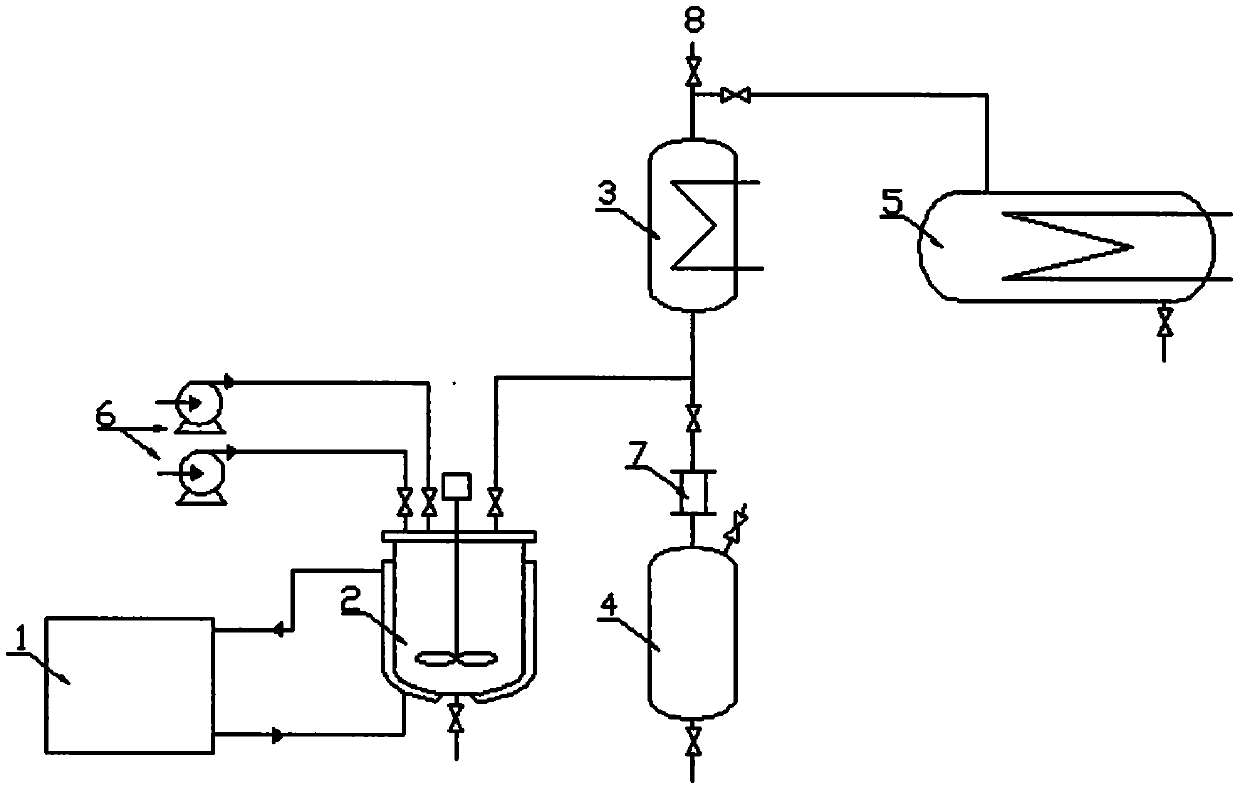

[0017] Such as figure 1 Shown, a kind of synthesis device of heptafluoroisobutyronitrile comprises high and low temperature cycle machine 1, reaction kettle 2, condenser 3, solvent recovery tank 4, freezing collection tank 5, liquid delivery pump 6, sight glass 7, vacuum system 8. The high and low temperature cycle machine is connected to the jacket of the reaction kettle, the liquid delivery pump 6 is connected to the top of the reaction kettle, the outlet on the top of the reaction kettle is respectively connected to the condenser 3 and the solvent recovery tank 4 through a tee, and the tee and the solvent recovery tank 4 are installed There is a tube-type sight glass 7; the outlet of the condenser 3 is connected to the frozen collection tank 5 and the vacuum system 8 through another tee. There is a vent on the top to connect with the atmosphere to balance the pressure in the solvent collection tank during operation. The device also includes an electric circuit, and the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com