Method for detecting the thickness of the upper layer of stratified solution

A liquid thickness and detection method technology, applied in the field of laser technology, can solve the problems of complex system and small measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0149] This example is specifically:

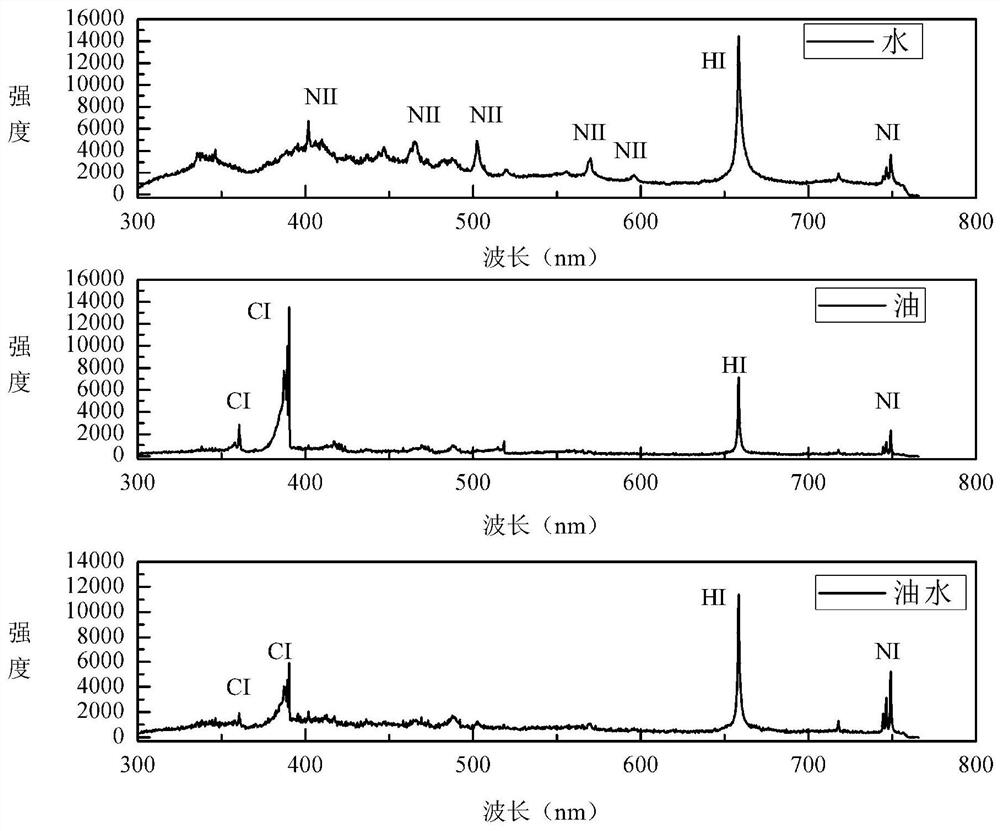

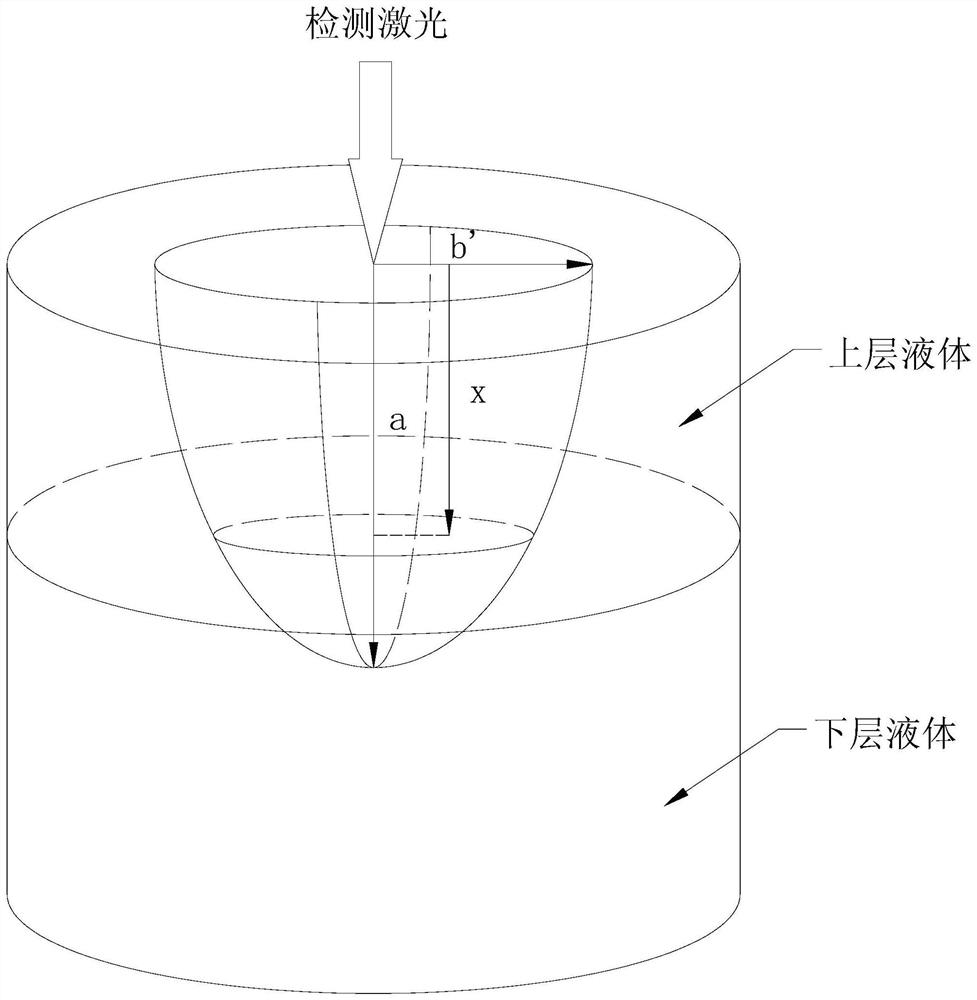

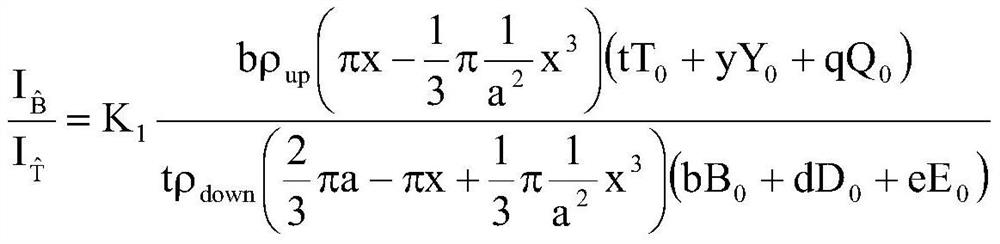

[0150] The 1064nm laser of Nd:YAG laser is used as the excitation light source, the pulse width is 10ns, the energy is about 80mJ, the spectral sampling frequency is 1HZ, and the sampling delay is 290μs. Plasma is excited and generated at the focal length position on the surface of the sample solution from top to bottom. The AvaSpec-ULS2048CL-EVO optical fiber spectrometer (AVANTES company) is used for signal detection in the experiment. The optical fiber probe collects spectral signals on the outer wall of the beaker. to computer, recorded by Avasoft software. In order to avoid the rise of the liquid level when adding oil droplets with a pipette, resulting in changes in the depth of focus, each time the liquid level changes, it is necessary to use a three-dimensional mobile platform to adjust the height of the sample, and use an energy meter (coherent LabMax energy meter) to measure the laser energy. Monitor, and place a fused silica gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com