Sintered neodymium iron boron containing SmFeN or SmFeC and preparation method thereof

A neodymium iron boron, sm2fe17-xmx technology, applied in the field of sintered neodymium iron boron and its preparation, can solve the problems of complex process and high cost, and achieve the effects of simple operation, low cost and high resistance to high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

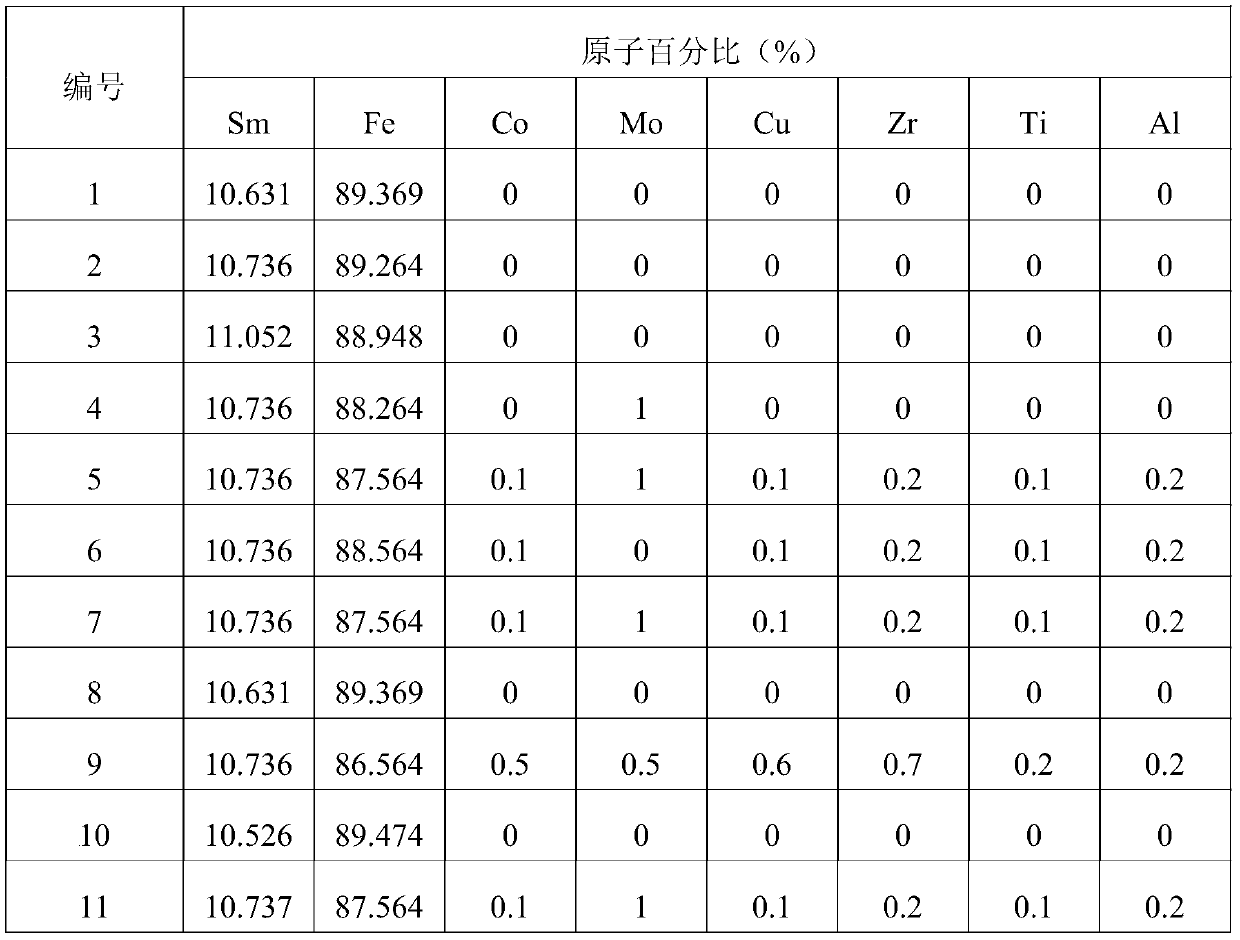

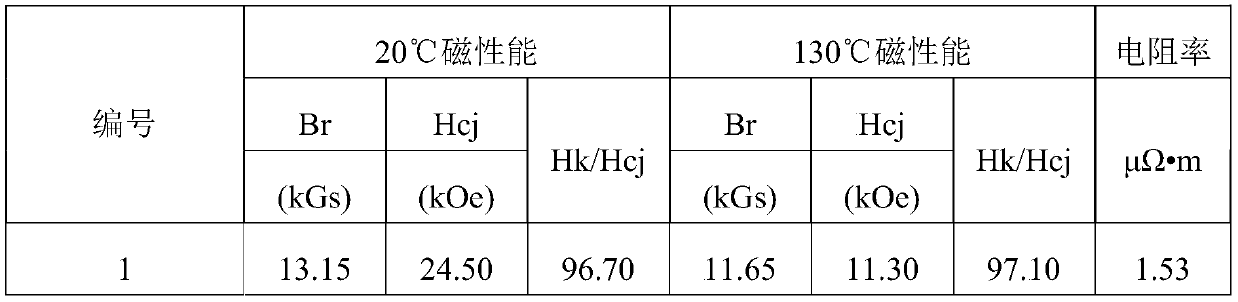

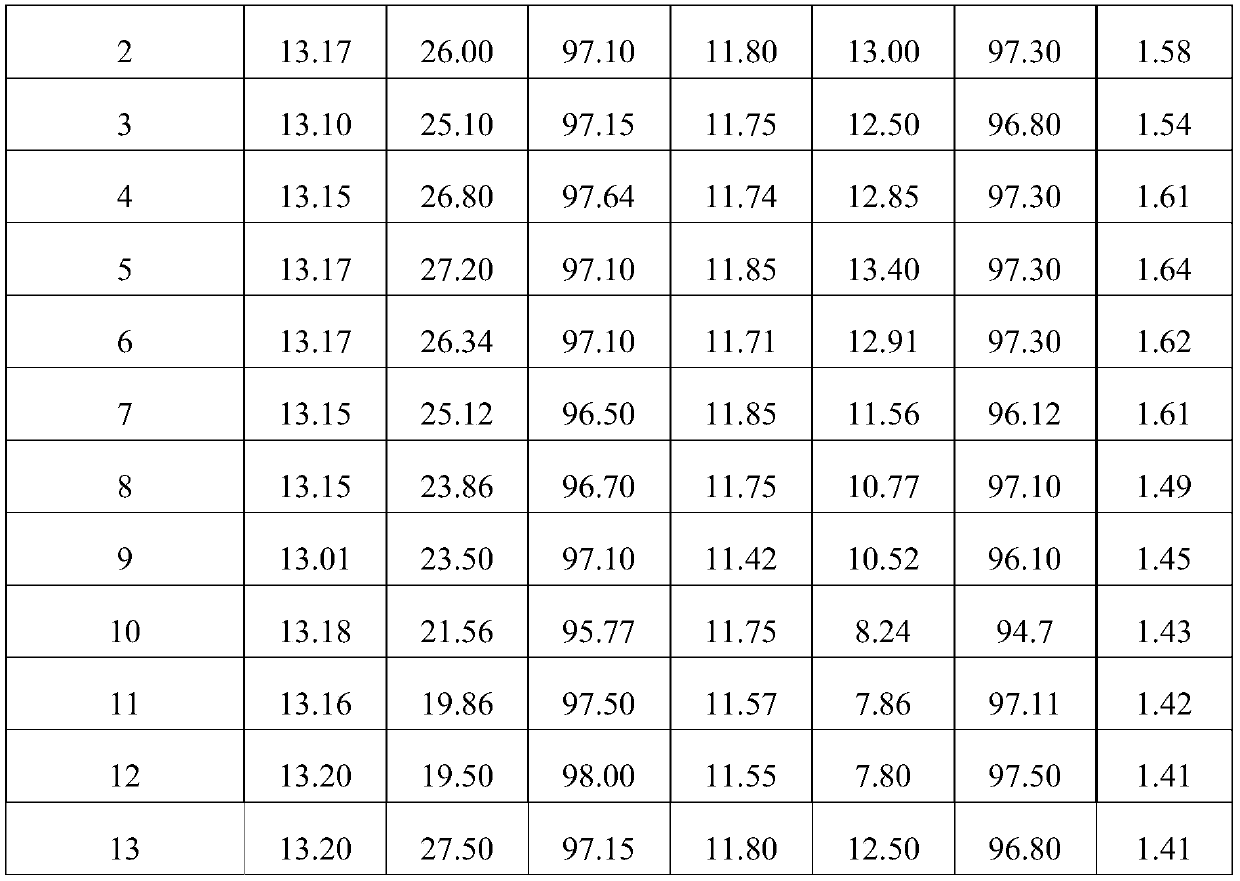

[0076] Step 1: According to the nominal composition as Sm 2 Fe 17-x m x (Its formula component content is shown in Table 1) raw material, it is added in the intermediate frequency vacuum induction quick-setting throwing belt furnace that its frequency is 2000Hz, adopts melt rapid quenching method to prepare Th 2 Zn 17 Structured Sm 2 Fe 17-x m x Master alloy, the melting temperature is 1600°C, the casting temperature is 1500°C, the thickness of the smelted alloy sheet is 0.3mm; after homogenization annealing, the smelted alloy sheet is placed in a vacuum furnace at 500°C ;The heating time of annealing is 4h, so that the composition of the alloy sheet is more uniform and the stress of the alloy sheet is eliminated;

[0077] Step 2: Put the Sm 2 Fe 17-x m x The master alloy is crushed into Sm with particle size D50=1mm 2 Fe 17-x m x powder, and then under the protection of argon, jet milling is carried out under the condition of 0.5-0.7MPa to prepare Sm with D50=3.0μ...

Embodiment 2~6

[0083] In addition to the optional Sm 2 Fe 17-x m x The formula composition content of the raw materials is different (as shown in Table 1), and the parameters in the rest of the preparation process are the same as the preparation process of Example 1.

Embodiment 7

[0085] In addition to the optional Sm 2 Fe 17-x m x The formula component content of the raw materials (as shown in Table 1) is different from the operation of step 6, and the parameters in steps 1 to 5 are the same as the preparation process of Example 1.

[0086] Step 6: NdFeB-Sm after grain boundary diffusion treatment 2 Fe 17-x m x The composite magnet is placed in a rotary carbonization furnace, and after 5 hours of carbonization treatment at a temperature of 550 ° C, the Sm of the sintered NdFeB surface layer 2 Fe 17-x m x The alloy is fully nitrided to form a Sm 2 Fe 17-x m x C y structure to achieve NdFeB magnets and Sm 2 Fe 17-x m x Combination of magnets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com