Redistribution layer structure and manufacturing method thereof

A technology for rewiring layers and manufacturing methods, applied in the field of semiconductor structures and their manufacturing, can solve the problems of abnormal solder ball height, small contact area, solder bridging, etc., to improve product reliability, increase contact area, and increase structural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described more fully with reference to the accompanying drawings of this embodiment. However, the present invention can also be embodied in various forms and should not be limited to the embodiments described herein. In the drawings, the thicknesses of layers and regions may be exaggerated for clarity. The same or similar component numbers represent the same or similar components, and the following paragraphs will not repeat them one by one.

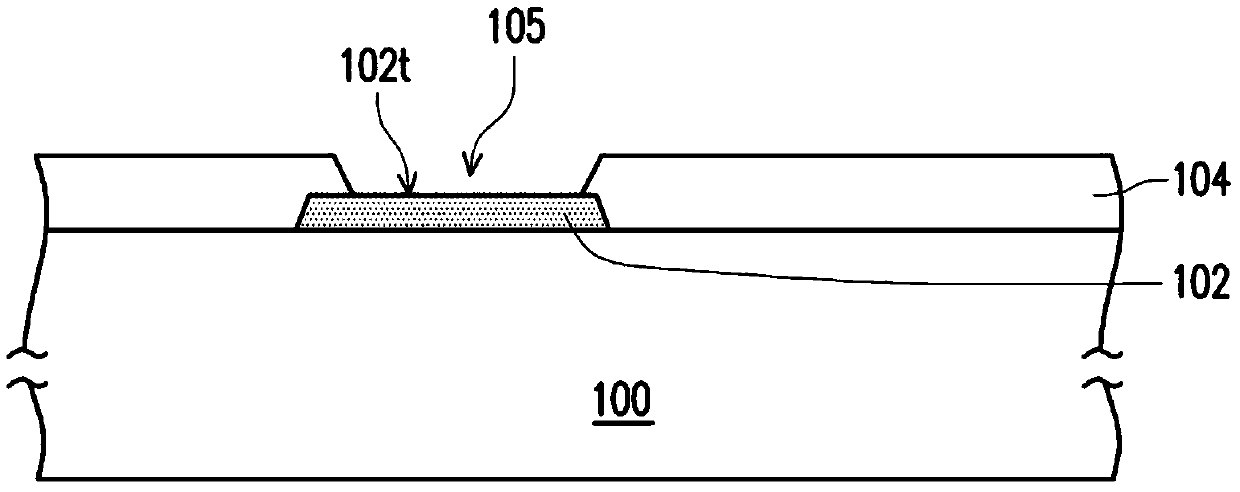

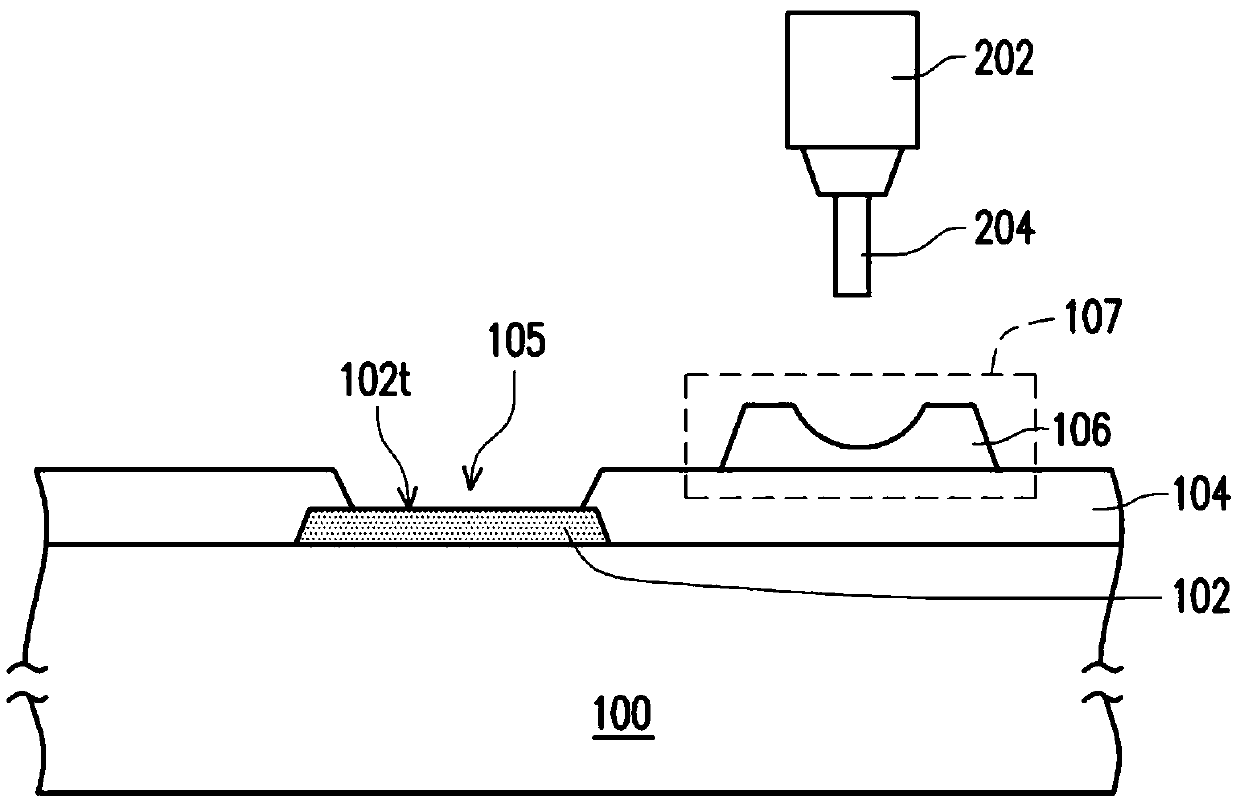

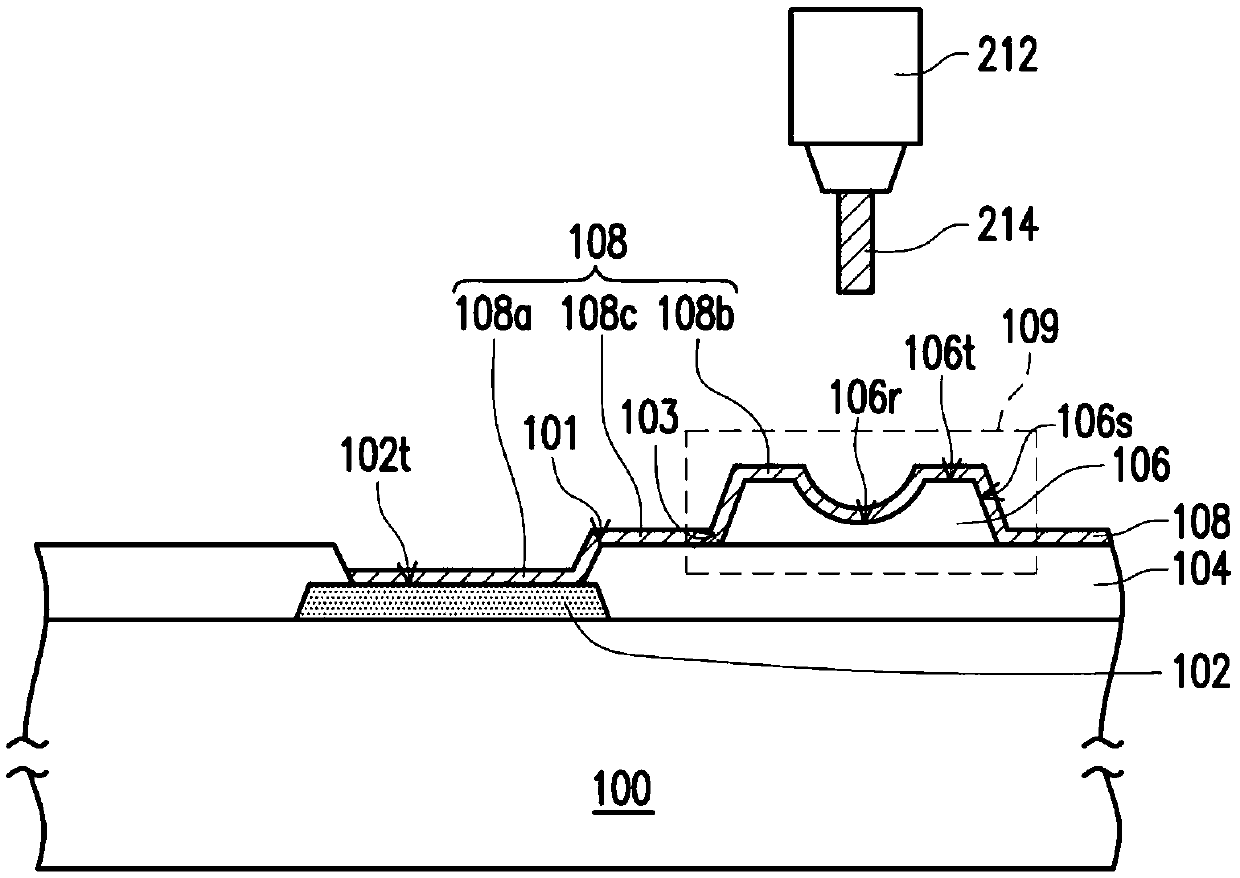

[0014] Figure 1A to Figure 1D is a schematic cross-sectional view of a manufacturing process of a redistribution layer structure according to an embodiment of the present invention. figure 2 yes Figure 1B An enlarged cross-sectional view of a part of the self-aligned structure. image 3 yes Figure 1C An enlarged cross-sectional view of a portion of the conductive layer. Figure 4 yes Figure 1D An enlarged cross-sectional view of a portion of the redistribution layer structure.

[0015] Ple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com