Tea leaf spreading device

A technology of tea and greening boxes, which is applied in the field of tea spreading devices, can solve the problems of high labor intensity, high labor cost, and long time consumption, and achieve the effects of reducing labor intensity, improving production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

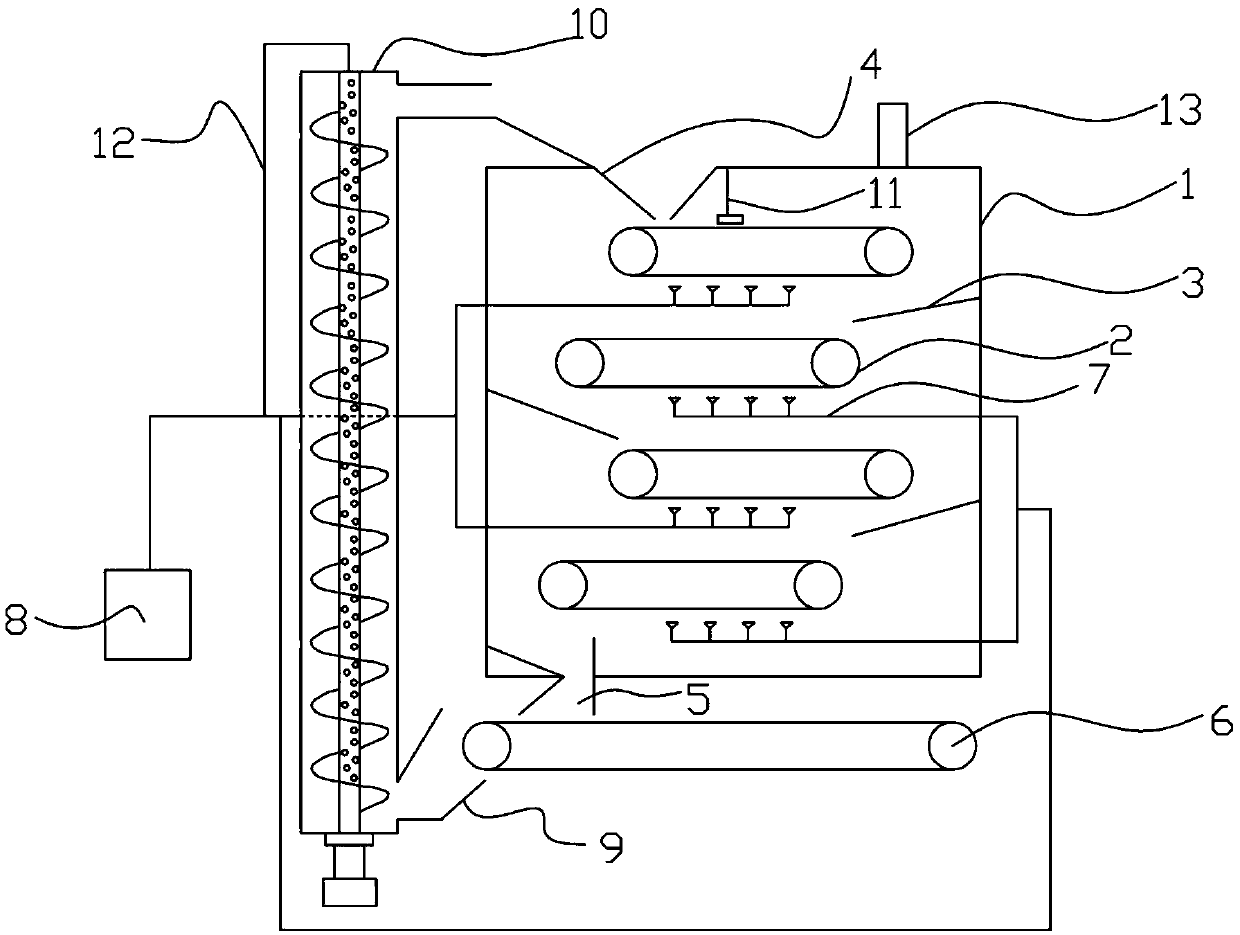

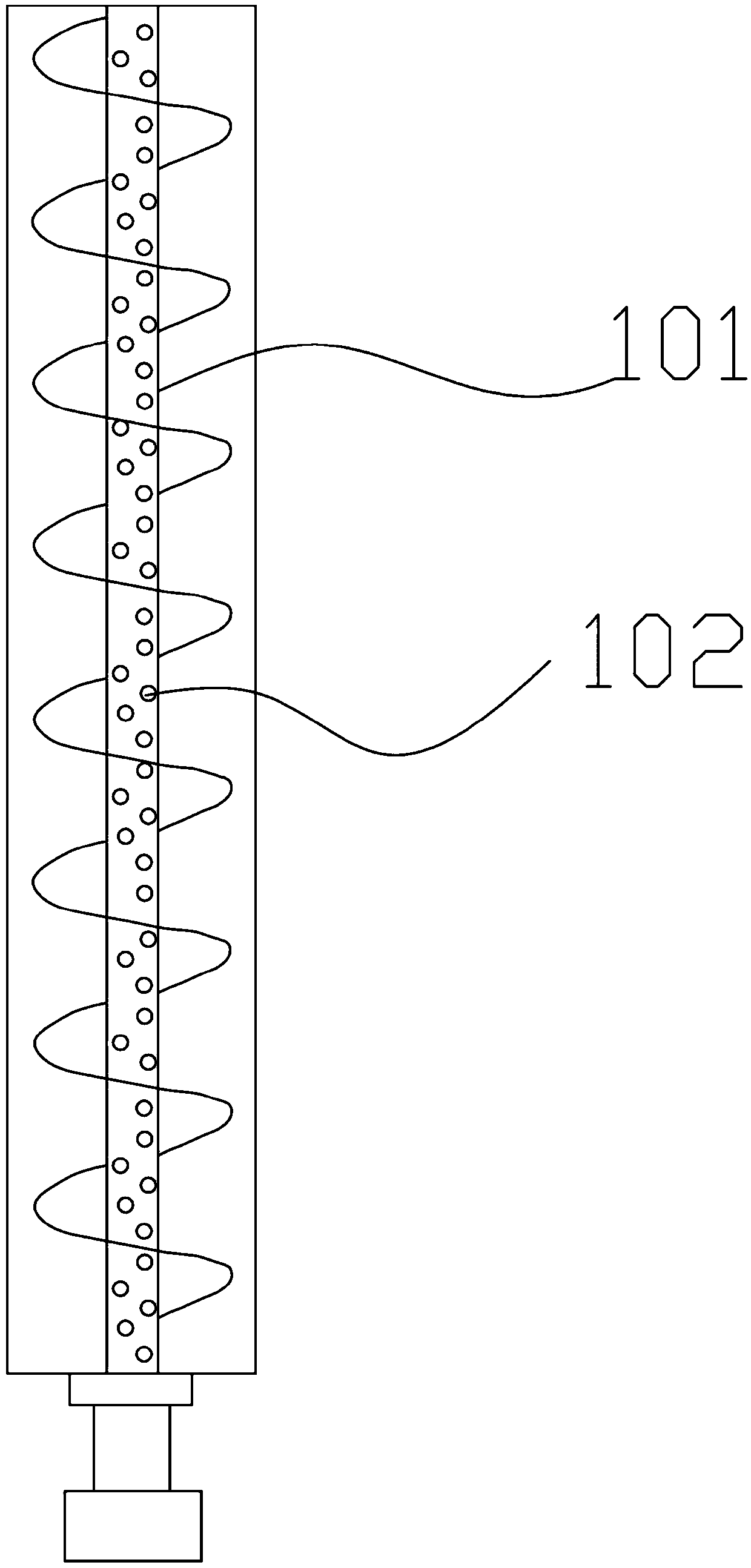

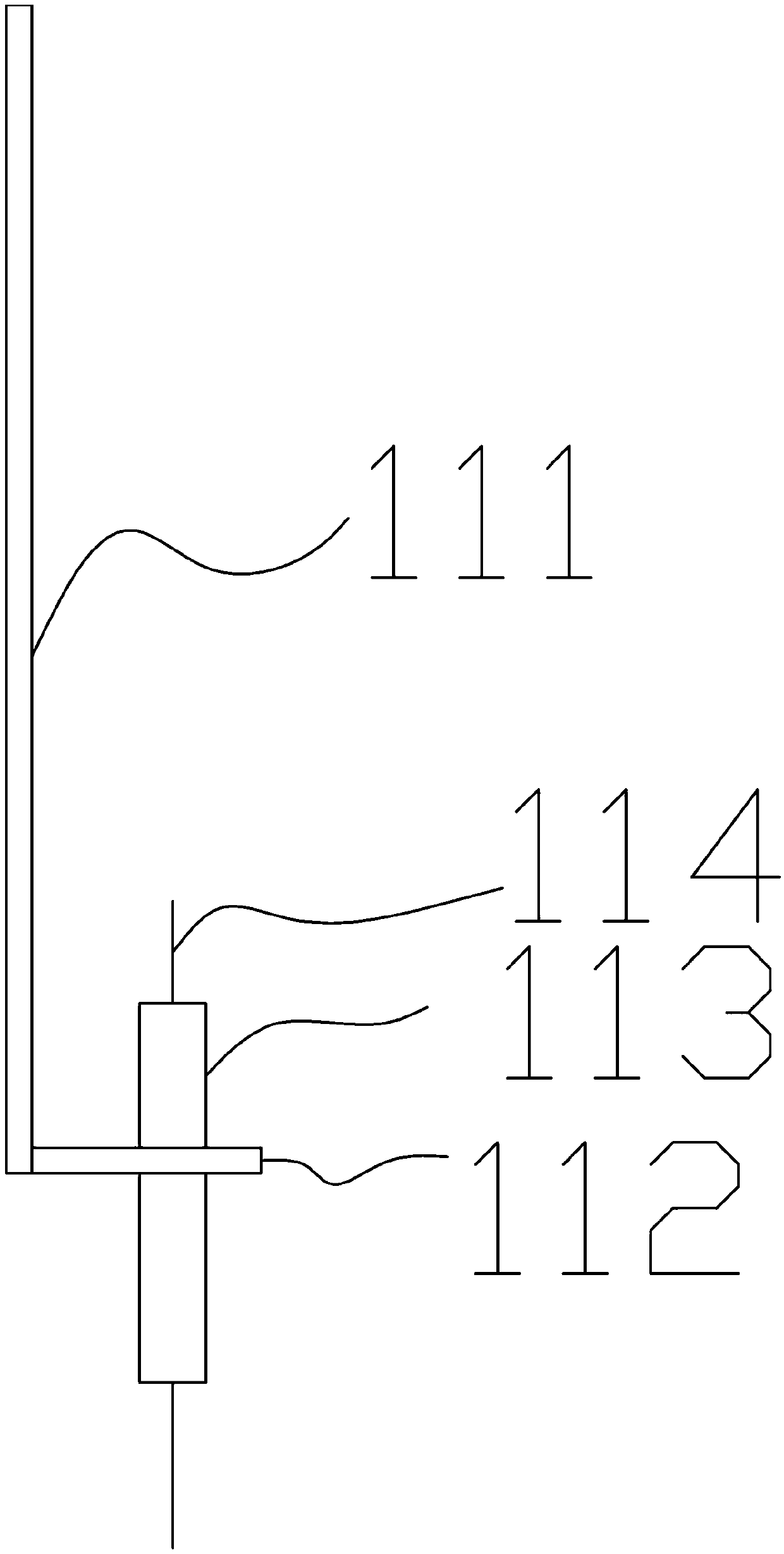

[0033] The green tea spreading device comprises a green spreading box 1, and several first conveyor belts 2 are arranged in parallel from top to bottom in the green spreading box 1, and the running directions of two adjacent first conveyor belts 2 are opposite, and two A first diversion plate 3 is provided between the adjacent first conveyor belts 2 to guide the material on the first conveyor belt 2 above to the first conveyor belt 2 below, and the top of the spreading box 1 is provided with a material inlet 4 is used to import tea leaves on the top first conveyor belt 2, and the bottom of the green spreading box 1 is provided with a tea discharge port 5 for introducing tea leaves on the second conveyor belt 6 below the green spreading box 1. The bottom of a conveyor belt 2 is provided with a first air duct 7 connected to a blower 8 .

[0034] Preferably, a second diversion plate 9 is provided below the second conveyor belt 6 to communicate with the inlet of the screw conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com