A method of cutting and preparing cast single crystal superalloy seed crystal

A high-temperature alloy, single crystal technology, applied in the direction of manufacturing tools, stone processing equipment, fine working devices, etc., can solve the problems of complex equipment and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

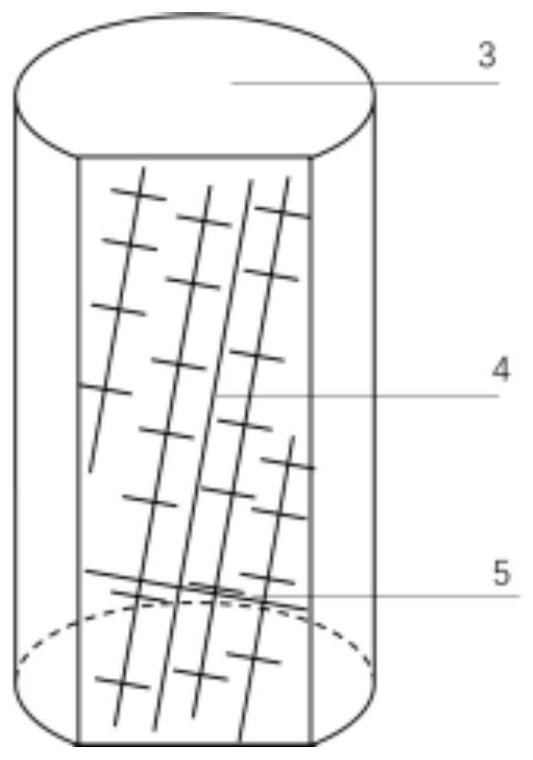

[0045] In this embodiment, a seed crystal with a diameter of 7 mm, a length of 20 mm, and a crystallographic orientation characteristic of [001] is cut.

[0046] The single crystal test rod used was cut from the nickel-based single crystal superalloy rod. The single crystal test rod has a diameter of 15 mm and a length of 30 mm.

[0047] The concrete process of this embodiment is:

[0048] Step 1, make a primary marking line parallel to the secondary dendrite direction

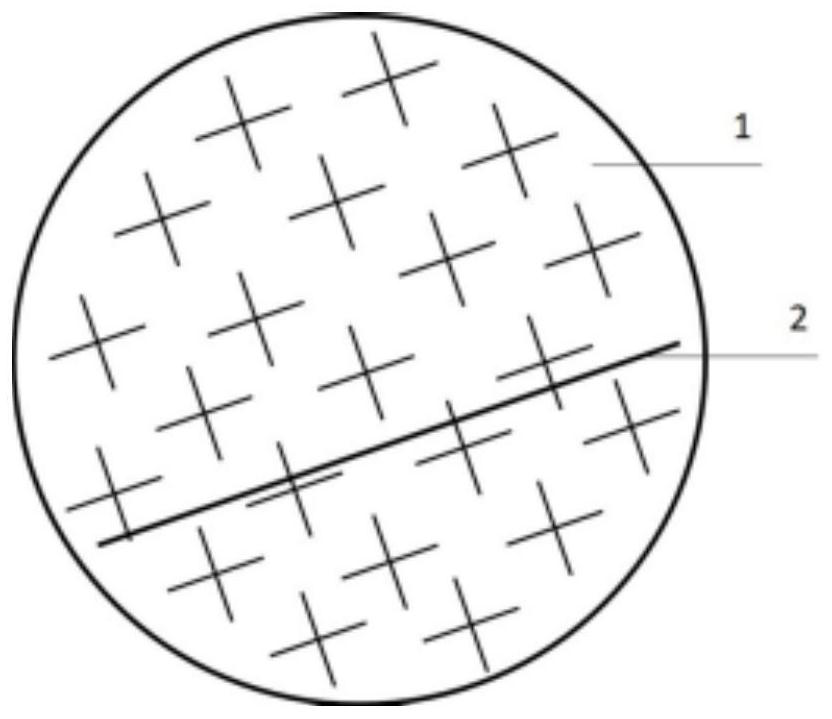

[0049] A standard metallographic preparation method is used to grind and polish one end face 1 of the single crystal test bar, and perform metallographic chemical corrosion on the end face.

[0050] Polishing treatment conditions: use 80#, 400#, 600#, 800#, 1000#, 1500#, 2000# water abrasive paper to polish one end surface of the single crystal test rod, and then perform polishing treatment on a polishing machine. The end face of the polished single crystal test rod is etched; the proportion of the etchant ...

Embodiment 2

[0067] In this embodiment, a seed crystal with a diameter of 10 mm, a length of 15 mm, and a [011] crystallographic orientation is cut.

[0068] The single crystal test rod used was cut from the cobalt-based single crystal superalloy rod. The single crystal sample used is φ15mm in diameter and 35mm in length. The concrete process of this embodiment is:

[0069] Step 1, make a primary marking line parallel to the secondary dendrite direction

[0070] One end face 1 of the single crystal test bar was ground and polished using standard metallographic preparation procedures. The end face is subjected to metallographic chemical etching. Polishing treatment conditions: Use 80#, 400#, 600#, 800#, 1000#, 1500#, 2000# water abrasive paper to polish one end face of the single crystal test rod, and then perform polishing treatment on a polishing machine. Carry out corrosion treatment to the polished end face; The etchant of described corrosion treatment matter is made of 4gCuSO 4 , ...

Embodiment 3

[0088] In this embodiment, a seed crystal with a diameter of 8 mm, a length of 12 mm, and a [111] crystallographic orientation is cut.

[0089] from Ni 3 Al-based single crystal superalloy rods used for intercepting single crystal test rods. The single crystal sample used is φ20mm in diameter and 40mm in length.

[0090] The concrete process of this embodiment is:

[0091] Step 1, make a primary marking line parallel to the secondary dendrite direction

[0092] One end face 1 of the single crystal test bar was ground and polished using standard metallographic preparation procedures. Use 80#, 400#, 600#, 800#, 1000#, 1500#, 2000# water-grinding sandpaper to polish one end face of the single crystal test rod in turn, and perform polishing on a polishing machine. Perform metallographic chemical etching on the polished end faces; the etchant used consists of 4gCuSO 4 , 20ml HCl, 20mlH 2 O prepared; corrosion 20s. After the end surface is corroded, a regular "ten" pattern ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com