N-valeraldehyde preparation method and special venturi ejector

A technology of n-valeraldehyde and injectors, which is applied in the field of chemical production, can solve the problems of low product positive-to-isotropic ratio and conversion rate, and the influence of reaction process parameters on reaction conversion effects, etc., to achieve the best positive-to-isotropic ratio and conversion rate, and to promote Gas-liquid mass transfer process, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

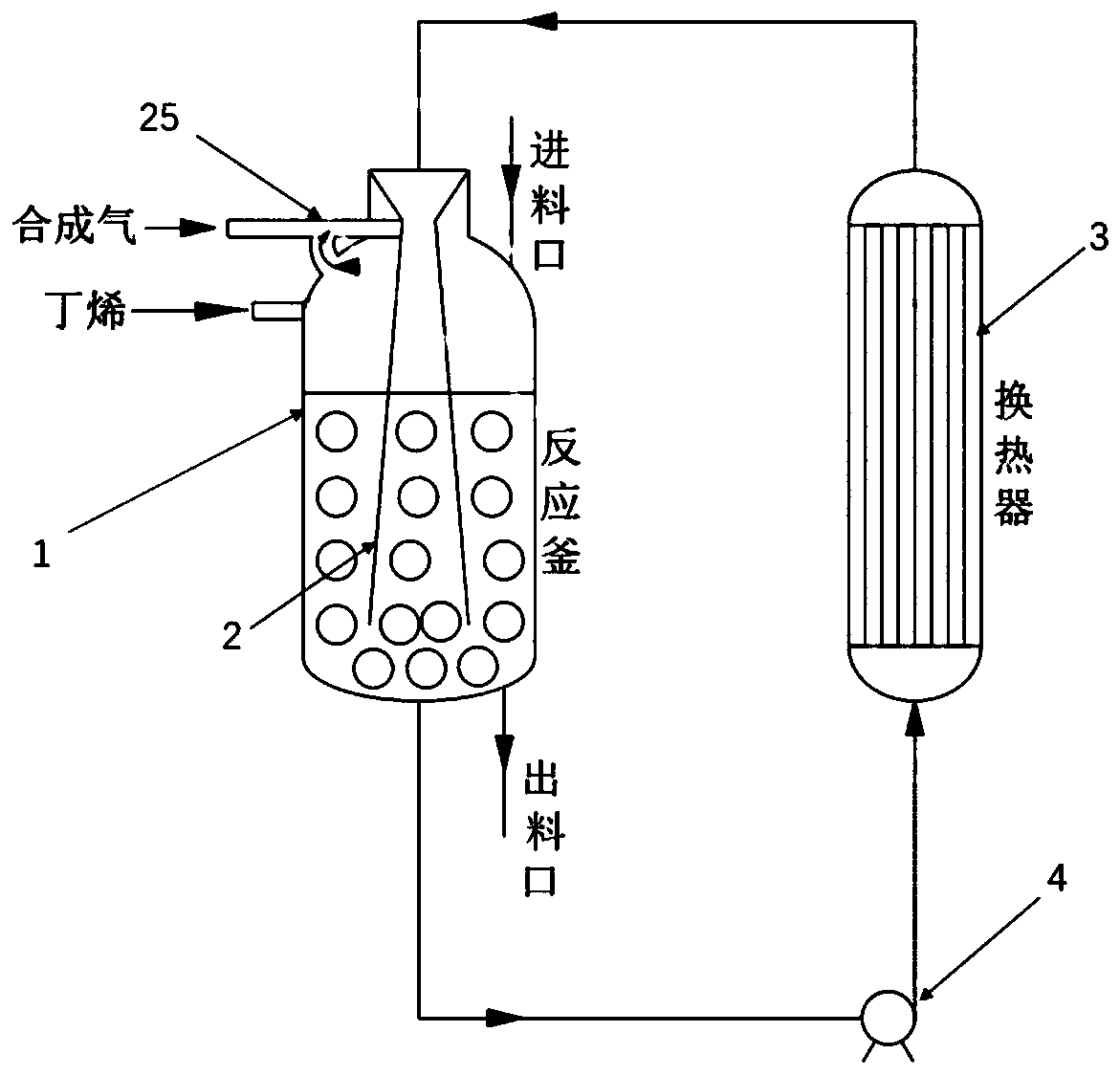

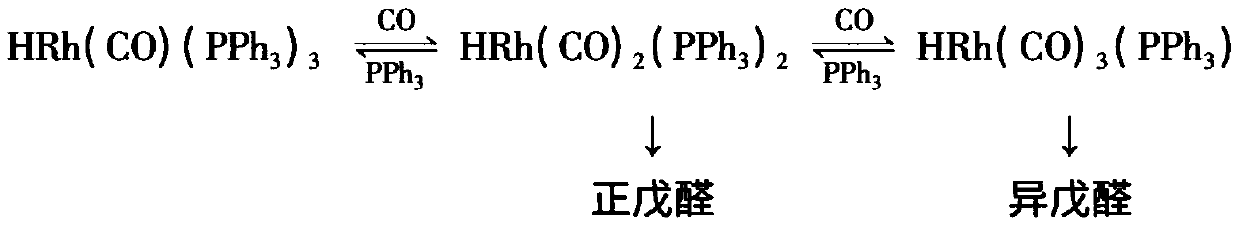

[0038] In the 5L loop reactor (reactor volume 5L), add a certain amount of toluene solvent 2650ml of rhodium dicarbonyl acetylacetonate and triphenylphosphine, the content of rhodium in the catalyst solution is 70 μg / g, and the molar ratio of TPP to Rh is 190. Feed synthesis gas (hydrogen to carbon monoxide volume ratio 1.1:1) into the reactor through the air inlet to a system pressure of 1MPa, turn on the circulation pump to make the liquid in the kettle flow slowly, vent, and repeat six times to replace the air in the loop reactor. Under pressure operation (synthesis gas pressure 0.6MPa), feed 700g of butene, raise the temperature to the preset reaction temperature of 100°C, and immediately fill in the mixed gas to the reaction pressure of 2.2MPa, adjust the circulation pump 4 until the flow rate reaches a certain value, which is recorded as the start of the reaction time. During the reaction process, the pressure of the synthesis gas connected to the reactor was controlled ...

Embodiment 2

[0042] In a 5L loop reactor (reactor volume 5L), add a certain amount of rhodium dicarbonyl acetylacetonate and triphenylphosphine toluene solvent 2650ml, catalyst rhodium content 60μg / g, TPP and Rh molar ratio 210. Feed synthesis gas (hydrogen to carbon monoxide volume ratio 1.1:1) into the reactor through the air inlet to a system pressure of 1MPa, turn on the circulation pump to make the liquid in the kettle flow slowly, vent, and repeat six times to replace the air in the loop reactor. Under pressure operation (synthesis gas pressure 0.6MPa), feed 700g of butene, raise the temperature to the preset reaction temperature of 105°C, and immediately fill in the mixed gas to the reaction pressure of 1.9MPa, adjust the circulation pump 4 until the flow rate reaches a certain value, which is recorded as the start of the reaction time. During the reaction process, the pressure of the synthesis gas connected to the reactor was controlled to be constant at 1.9MPa, and the temperature...

Embodiment 3

[0046] In a 5L loop reactor (reactor volume 5L), add a certain amount of toluene solvent 2650ml of rhodium dicarbonyl acetylacetonate and triphenylphosphine, catalyst rhodium content 80μg / g, TPP and Rh molar ratio 250. Feed synthesis gas (hydrogen to carbon monoxide volume ratio 1.1:1) into the reactor through the air inlet to a system pressure of 1MPa, turn on the circulation pump to make the liquid in the kettle flow slowly, vent, and repeat six times to replace the air in the loop reactor. Under pressure operation (synthesis gas pressure 0.6MPa), feed 700g of butene, raise the temperature to the preset reaction temperature of 95°C, and immediately fill in the mixed gas to the reaction pressure of 2.0MPa, adjust the circulation pump 4 until the flow rate reaches a certain value, which is recorded as the start of the reaction time. During the reaction process, the pressure of the synthesis gas connected to the reactor was controlled to be constant at 2.0MPa, and the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com