Organosilicon composition, reaction product, and preparation method and application of reaction product

A technology of reaction products and compositions, used in adhesive additives, non-polymer adhesive additives, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

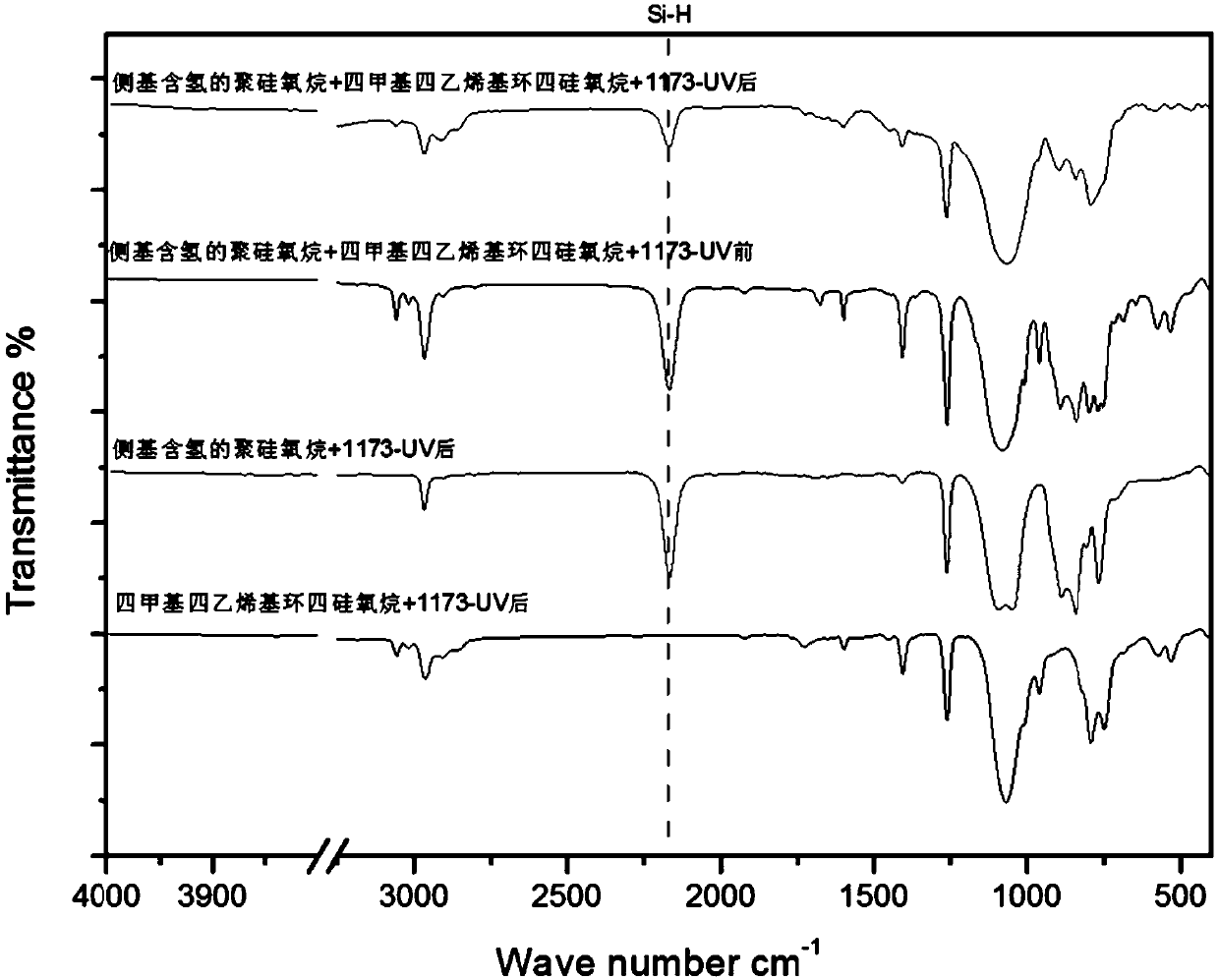

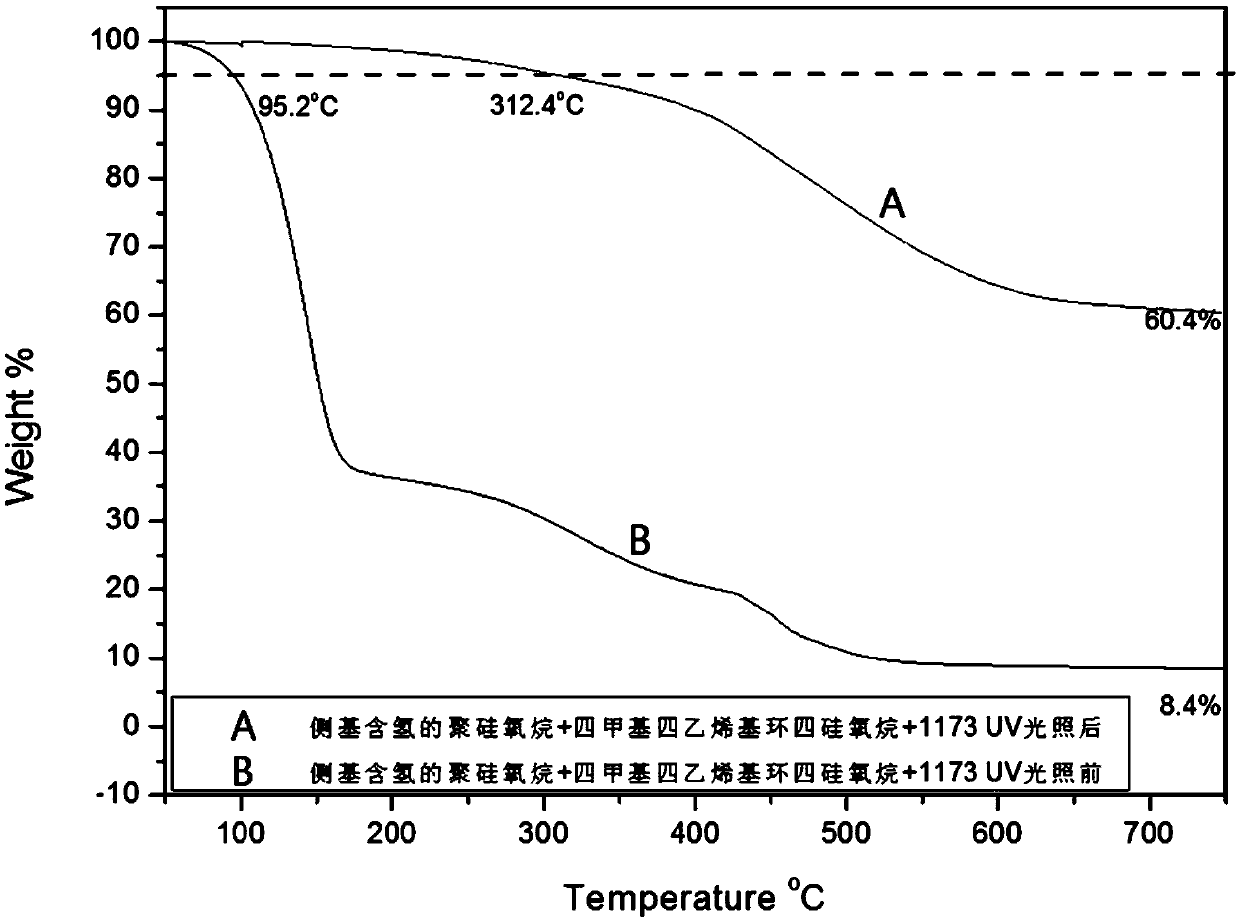

[0053] The photocurable silicone in this embodiment is prepared according to the following method:

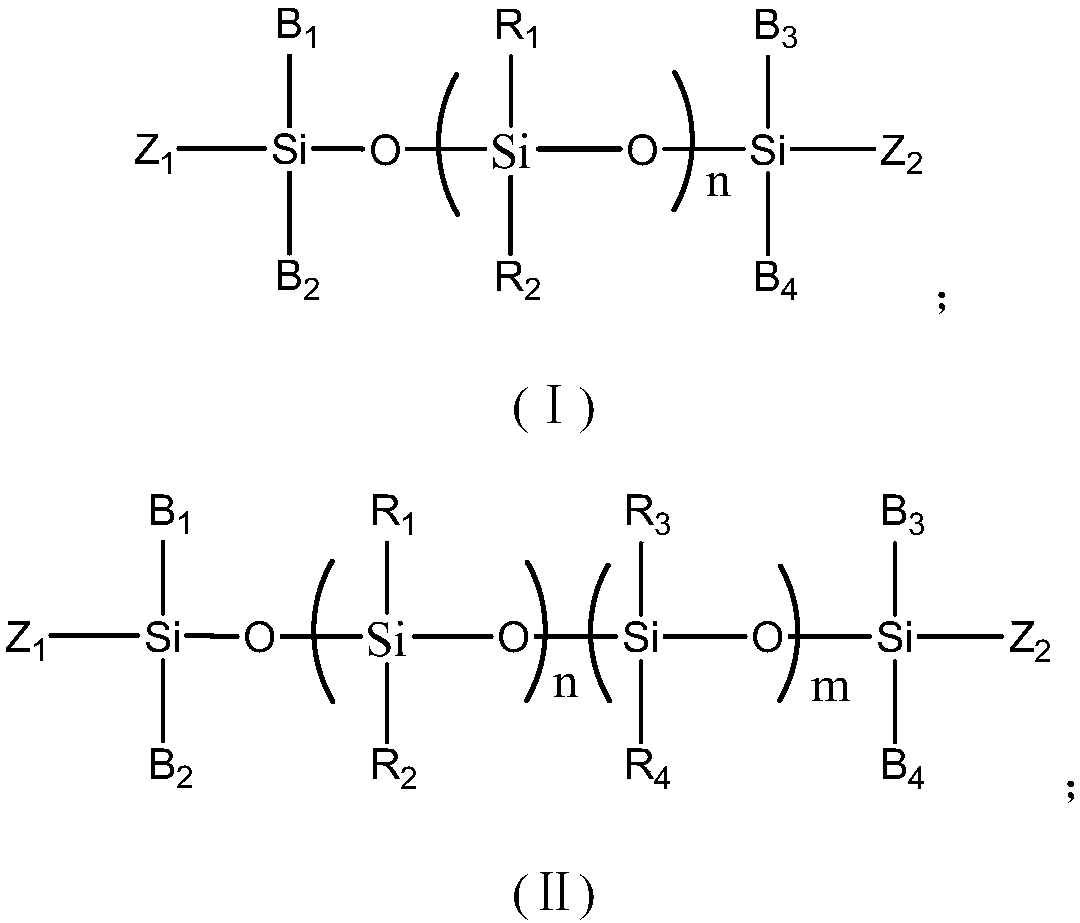

[0054] (1) The linear polysiloxane containing H in the side group is used as a raw material, mixed evenly with the siloxane of the structure shown in the formula (I) and 4wt% photoinitiator 1173; the unsaturated polysiloxane shown in the formula (I) Hydrocarbyl compounds, R 1 for vinyl, R 2 , B 1 , B 2 , B 3 , B 4 Both are methyl, Z 1 ,Z 2 Both - OSiPh(Me) 2 , n is 5; the molar ratio of Si-H in the linear polysiloxane containing H in the side group to the vinyl group in the siloxane of the structure shown in formula (I) is 1.4:1;

[0055] (2) UV-cure the mixture of step (1) under the protection of an inert gas, the UV wavelength is 280nm, and the light intensity is 50 μW / cm 2 ;, the reaction time is 5min, and the photocurable silicone with a curing depth of 50nm is prepared.

Embodiment 2

[0057] On the basis of embodiment 1, the present embodiment is different in that: R 1 For ethynyl groups, 2 wt% antioxidant Irganox-1010 was added to the mixture, and other conditions remained unchanged, to obtain a photocurable silicone with a curing depth of 80 nm.

Embodiment 3

[0059] This example is based on Example 2, with the difference that 8 wt% of the defoamer BASF A10 is added to the mixture, and other conditions remain unchanged, to obtain a photocurable silicone with a curing depth of 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com