Ultrahigh-content micro-emulsified cutting fluid for machining

A mechanical processing and micro-emulsification technology, which is applied in the direction of additives, petroleum industry, lubricating compositions, etc., can solve the problems of short service life, simultaneous processing of ferrous metals and non-ferrous metals, etc., and achieve the effect of solving contradictions and excellent rust prevention of ferrous metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

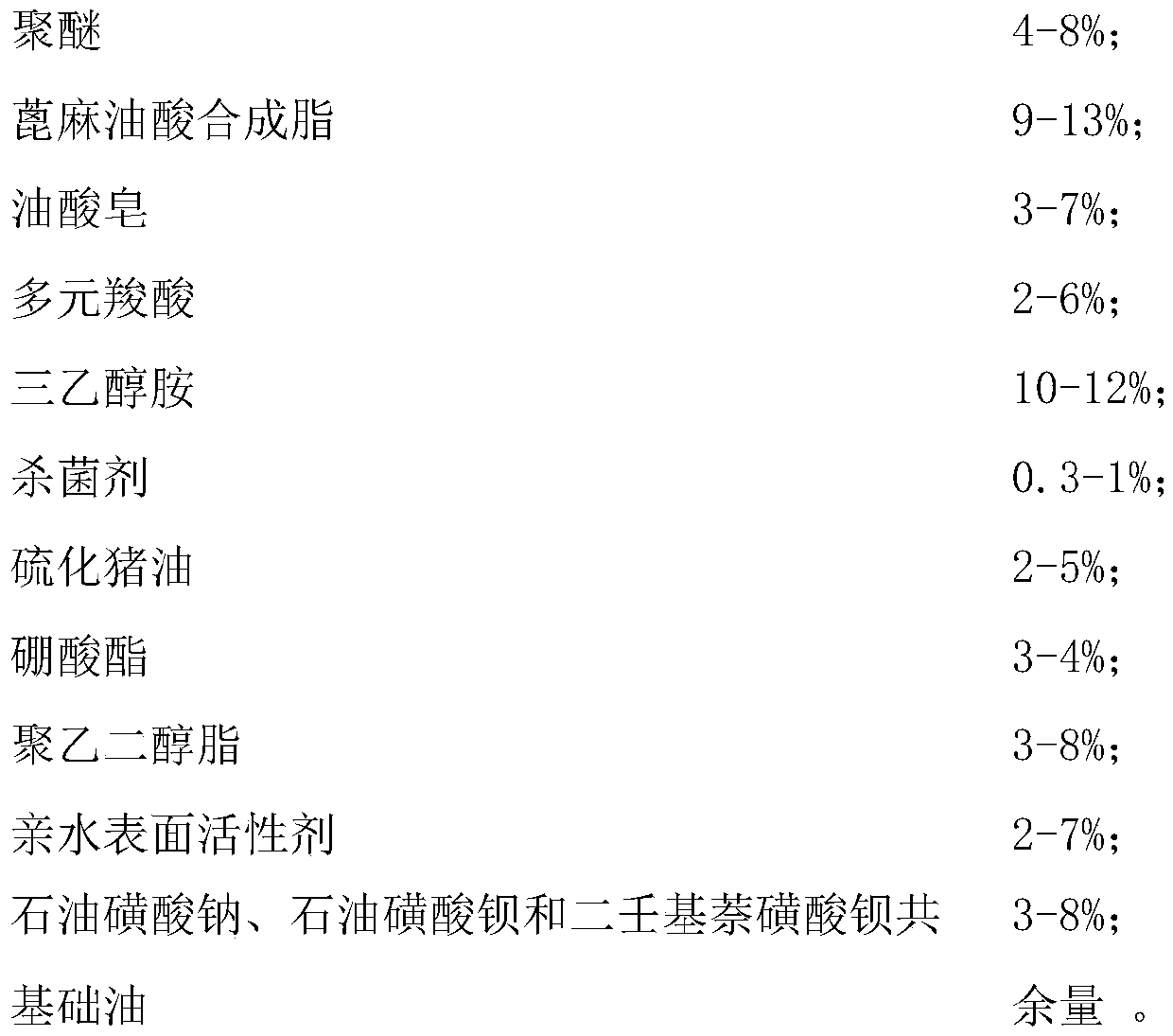

[0035]

[0036]

[0037] in:

[0038] The ratio of sodium petroleum sulfonate, barium petroleum sulfonate and barium dinonyl naphthalenesulfonate is 45:40:15, and the compounding is completed at 55°C

Embodiment 2

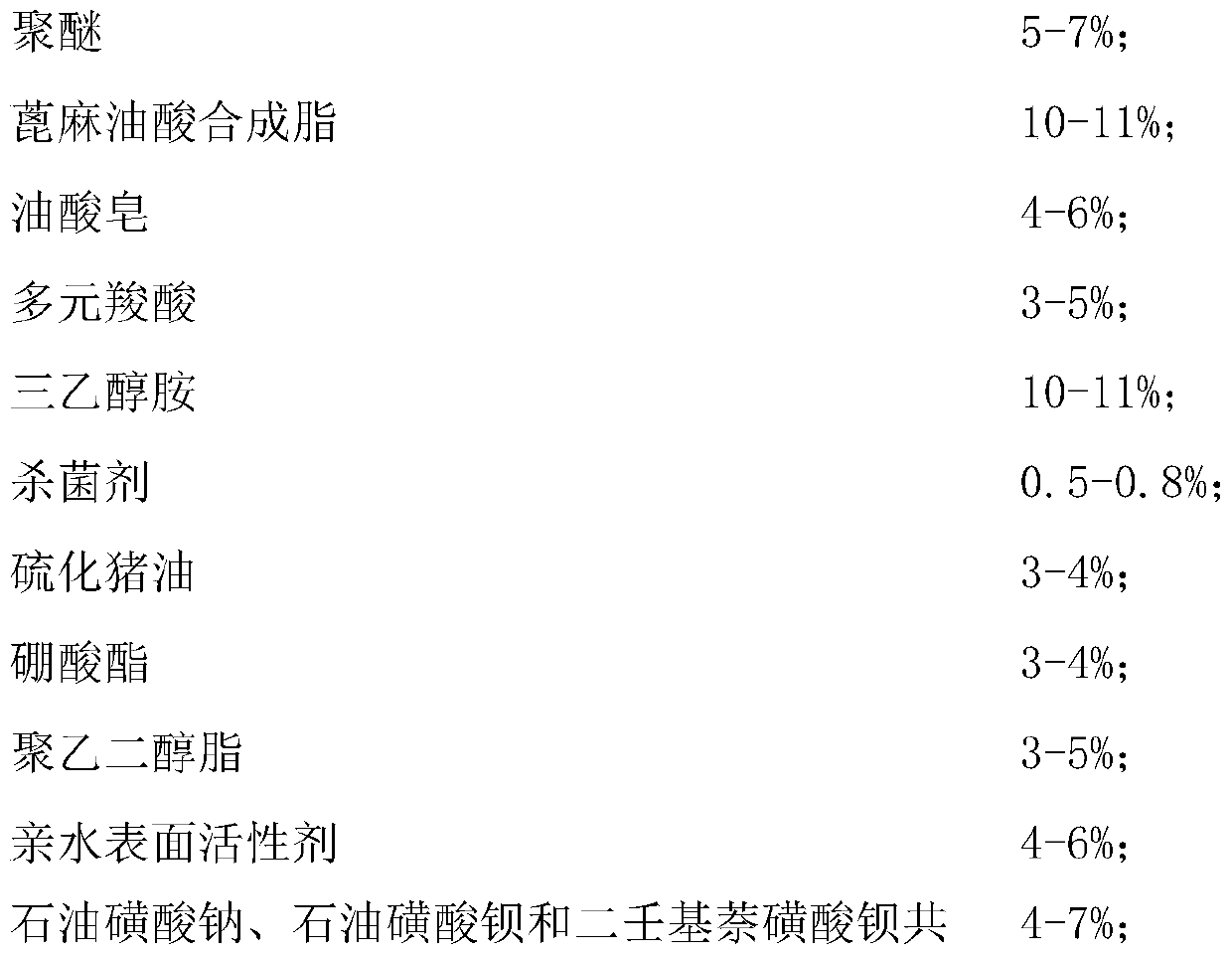

[0040]

[0041] in:

[0042] The ratio of sodium petroleum sulfonate, barium petroleum sulfonate and barium dinonyl naphthalenesulfonate is 45:40:15, and the compounding is completed at 55°C

Embodiment 3

[0044]

[0045]

[0046] in:

[0047] The ratio of sodium petroleum sulfonate, barium petroleum sulfonate and barium dinonyl naphthalenesulfonate is 45:40:15, and the compounding is completed at 55°C.

[0048] The following is the experimental data of the cutting fluid using the above ingredients:

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com