A fully synthetic cutting fluid for heavy-duty metal processing and its preparation method and application

A metal processing and total synthesis technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve problems such as harm to unborn children, impact on the environment, human sterility, etc., to achieve good lubrication, extreme pressure, excellent anti-rust performance, avoid the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

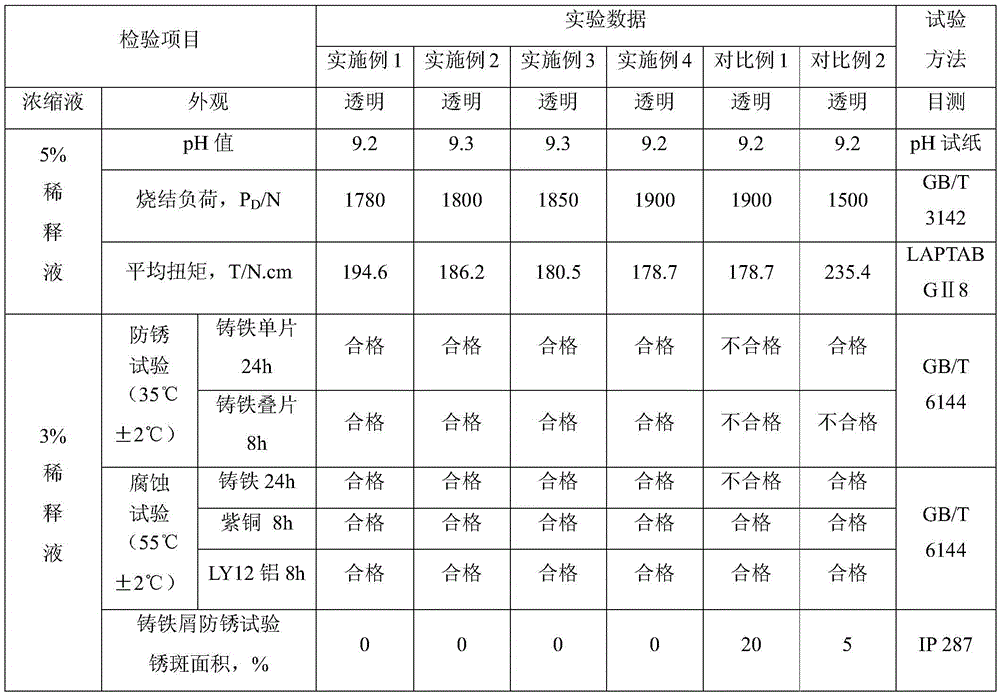

Examples

Embodiment 1

[0026] A fully synthetic cutting fluid for heavy-duty metal processing, consisting of the following components by mass percentage: 5% monoethanolamine, 15% triethanolamine, 2% p-toluenesulfonamidocaproic acid, 2% decadioic acid, Triazine triaminocaproic acid 2%, 2-amino-2-methyl-1-propanol 4%, dimer acid 6%, polyether (average molecular weight 2000g / mol, cloud point 20 ℃ trans-block poly ether) 15%, n-octanoic acid 6%, ethylenediaminetetraacetic acid disodium salt 1%, benzotriazole 0.2%, ethoxy phosphate 0.8%, water balance.

[0027] Preparation method: first add monoethanolamine, triethanolamine and dimer acid into the reaction kettle, stir at room temperature for 60 minutes until uniform and transparent, then add water, p-toluenesulfonamidocaproic acid, decanedibasic acid, triazinetriamino Hexanoic acid, ethylenediaminetetraacetic acid disodium salt, benzotriazole, ethoxy phosphate, stirred at room temperature for 90 minutes until uniform and transparent, then added 2-amino-...

Embodiment 2

[0030] A fully synthetic cutting fluid for heavy-duty metal processing, which consists of the following components in terms of mass percentage: diethanol monoisopropanolamine 8%, triethanolamine 17%, p-toluenesulfonylaminocaproic acid 2.5%, undecyl 2.5% dibasic acid, 2% triazine triaminocaproic acid, 5% 3-amino-4-octanol, 8% trimer acid, polyether (average molecular weight 2600g / mol, trans block with cloud point 30°C) Polyether) 18%, isooctanoic acid 7%, ethylenediaminetetraacetic acid tetrasodium salt 1.5%, benzotriazole derivatives 0.3%, fatty alcohol modified phosphate ester 1.2%, water balance.

[0031] Preparation method: first add diethanol monoisopropanolamine, triethanolamine and trimer acid into the reaction kettle, stir at room temperature for 30 minutes until uniform and transparent, then add water, p-toluenesulfonamide caproic acid, undecyl binary Acid, triazine triaminocaproic acid, ethylenediaminetetraacetic acid tetrasodium salt, benzotriazole derivatives, fatty...

Embodiment 3

[0034] A fully synthetic cutting fluid for heavy-duty metal processing, which consists of the following components by mass percentage: 15% monoisopropanolamine, 10% triethanolamine, 2.5% p-toluenesulfonylaminocaproic acid, dodecyl carbon binary 3% triazine triaminocaproic acid, 2.5% triazine triaminocaproic acid, 5% diglycolamine, 8% ricinoleic acid polyester, polyether (average molecular weight 3200g / mol, trans block polyether with cloud point 40°C) 22 %, isononanoic acid 8%, fatty alcohol ether carboxylic acid 1.8%, methyl benzotriazole derivatives 0.5%, fatty alcohol modified phosphate ester 1.5%, and the balance of water.

[0035]Preparation method: first add monoisopropanolamine, triethanolamine and ricinoleic acid polyester into the reaction kettle, stir at room temperature for 50 minutes until uniform and transparent, then add water, p-toluenesulfonylaminocaproic acid, dodecyl carbon binary Acid, triazine triaminocaproic acid, fatty alcohol ether carboxylic acid, methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com