High-temperature-resistant composite filter material with good dust removal effect

A compound filtration and high-temperature-resistant technology, which is applied in the direction of filtration and separation, membrane filters, chemical instruments and methods, etc., can solve the problems of poor dust removal effect and low breaking strength, achieve good dust removal effect, improve high-temperature resistance performance, and improve The effect of filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a high temperature resistant composite filter material with good dust removal effect comprises the following steps:

[0035] 1) Mix chopped polyimide fibers with a fineness of 2dtex and a length of 51 mm and chopped basalt fibers with a diameter of 7 μm and a length of 51 mm according to a ratio of 3:1, then open and card to prepare mixed fibers;

[0036] The prepared mixed fiber is used as the facing layer and the bottom layer;

[0037] 2) The warp and weft density is 50×60 / 10cm and the weight is 650g / m 2 The basalt fiber woven fabric is placed between the facing layer and the bottom layer as the base layer;

[0038] 3) Put the facing layer, the base fabric layer and the bottom layer together into the acupuncture machine for pre-acupuncture, the pre-acupuncture depth is 8mm, and the pre-acupuncture density is 80 pricks / cm 2 ;

[0039] 4) After pre-acupuncture, put it into the spunlace production line for spunlace, the spunlace speed is 6m / min...

Embodiment 2

[0043] Repeat the method of Example 1, but the speed of spunlace is 4m / min.

Embodiment 3

[0045] Repeat the method of Example 1, but the speed of spunlace is 7m / min.

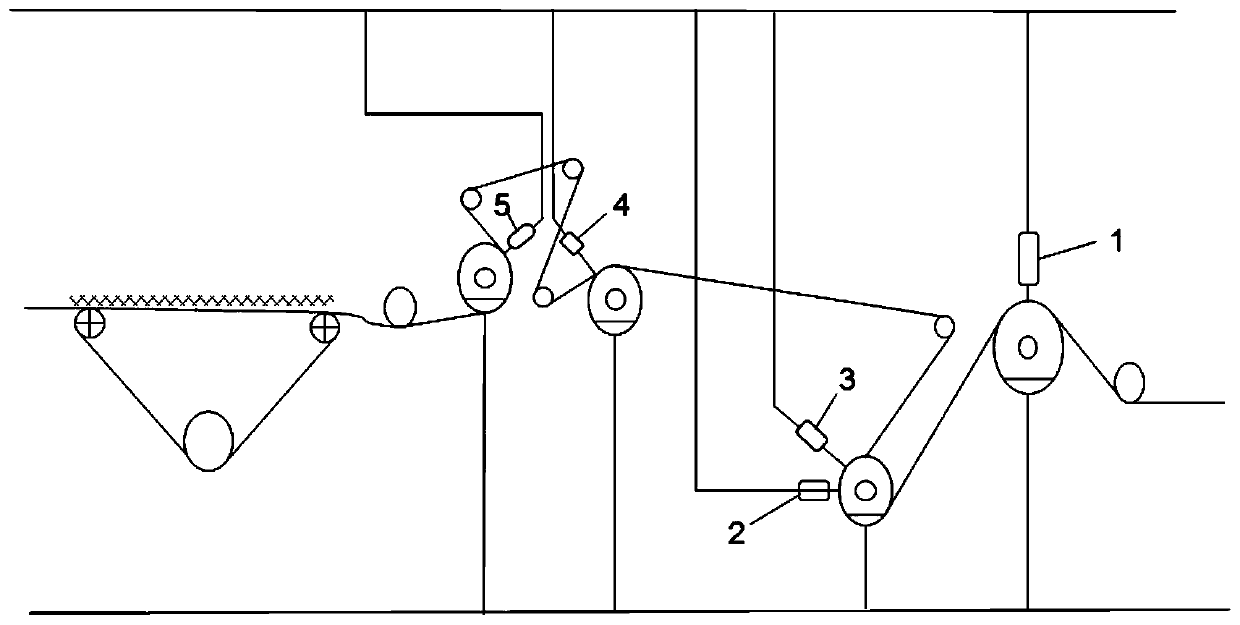

[0046] Specifically, steps 1), 2), and 3) of Embodiment 1 to Embodiment 3 are all carried out on the carding and laying production line. The carding and laying production line includes a carding machine, a web laying machine, a drafting machine and a pre-needling machine, and the carding and laying production line includes two production lines, which can prepare the facing layer and the bottom layer at the same time, and then put the base cloth layer into the Pre-needling is carried out between the facing layer and the bottom layer. Easy to use and save time.

[0047] Specifically, the spunlace machine is an AquaJet spunlace production line.

[0048] Specifically, the heat setting equipment is Bruckner heat setting equipment.

[0049] Specifically, the silane coupling agent is A-151.

[0050] In the preparation method of the present invention, the speed of spunlace is 4-7m / min, which can further ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com