Online hot laminating process of flocking belt of vehicle EPDM glass guide groove sealing strip

A technology for glass run channels and sealing strips, which is applied to household components, household appliances, and other household appliances. It can solve problems such as insufficient environmental protection, complicated process, and poor flocking effect, and achieve energy saving, uniform fluff coverage, and reduced noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

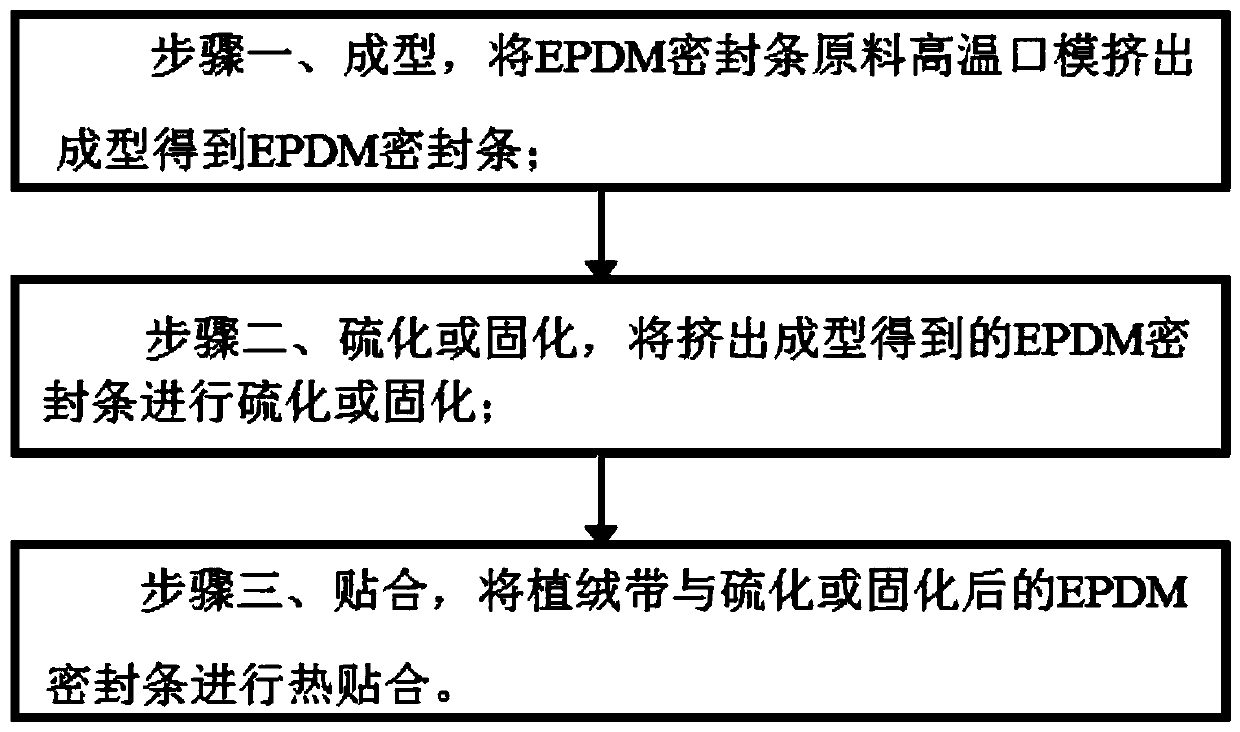

[0037] Refer to attached figure 1 , a kind of automobile EPDM glass run channel sealing strip flocking tape online thermal bonding process of the present embodiment, vulcanize or solidify the produced EPDM sealing strip and carry out flocking tape thermal bonding, utilize vulcanized or cured EPDM sealing strip The built-in temperature heat-melts the flocking tape, which not only utilizes the waste heat that is beneficial to environmental protection and energy saving, but also realizes the online lamination during the production process of EPDM sealing strips, which reduces the cumbersome process of subsequent flocking and saves process, reducing costs. At the same time, compared with the EPDM sealing strip produced by the traditional electrostatic flocking, the EPDM sealing strip produced by the thermal lamination process has better flocking effect and more fluff coverage. Even, during use, the possibility of increased friction with the glass due to uneven flocking is reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com