Mechanochemical preparation method of Ti3C2Tx with high lithium storage capacity

A mechanochemical method and mechanochemical reaction technology, applied in electrochemical generators, carbides, titanium carbides, etc., can solve problems such as low capacity, and achieve the effects of low cost, low pollution, and simple and controllable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

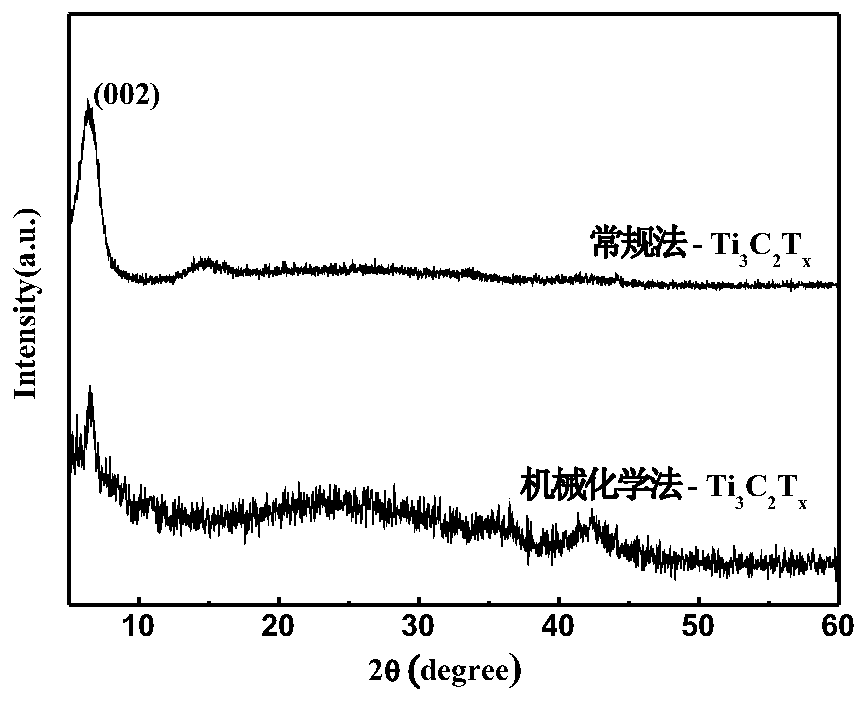

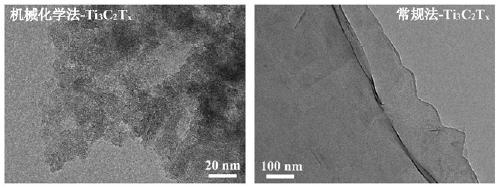

[0022] Ti 3 AlC 2 Put it into a stainless steel reactor with a total sample weight of 1.0 g, fill it with nitrogen and seal it, and react mechanically at 300 rpm for 12 hours. Dissolve 15.0g of sodium hydroxide in 10mL of deionized water, cool to room temperature, pass nitrogen gas for 5 minutes, add strong alkali solution into the above reactor, fill with nitrogen gas again to seal, rotate at 300rpm, and perform mechanochemical reaction for 12 hours. After the above reactor was cooled to room temperature, deionized water was added under nitrogen protection and ice bath. After cooling to room temperature, the mixed solution was centrifuged at 9000 rpm until neutral. Add deionized water to the precipitate and centrifuge at 3500rpm for 5min, take the supernatant, freeze-dry, and finally obtain the mechanochemically prepared Ti 3 C 2 T x .

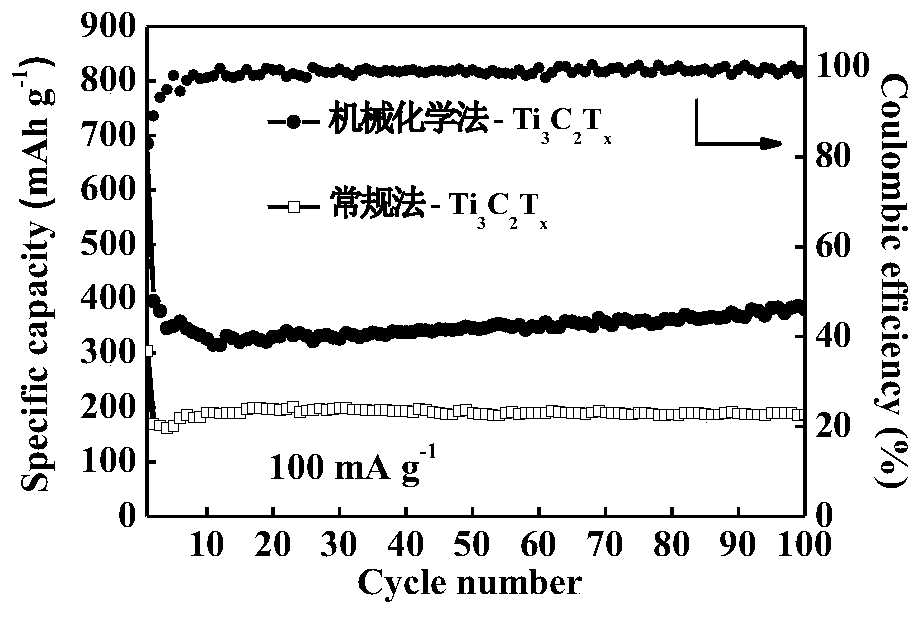

[0023] Take the mass ratio of 8:1:1, take the Ti prepared by Mechanochemistry in Example 1 3 C 2 T x, conductive carbon black, sodi...

Embodiment 2

[0025] Ti 3 AlC 2 Put it into a stainless steel reactor with a total sample weight of 1.0 g, fill it with nitrogen and seal it, and react mechanically at 300 rpm for 12 hours. Dissolve 7.5g of sodium hydroxide in 10mL of deionized water, cool to room temperature, and pass nitrogen gas for 5 minutes, then add the strong alkali solution into the above-mentioned reactor, fill it with nitrogen again and seal it, the rotation speed is 300rpm, and the mechanochemical reaction takes 12 hours. After the above reactor was cooled to room temperature, deionized water was added under nitrogen protection and ice bath. After cooling to room temperature, the mixed solution was centrifuged at 9000 rpm until neutral. Add deionized water to the precipitate and centrifuge at 3500rpm for 5min, take the supernatant, freeze-dry, and finally obtain the mechanochemically prepared Ti 3 C 2 T x .

[0026] Take the mass ratio of 8:1:1, and take the Ti prepared by Mechanochemistry in Example 2 3 C...

Embodiment 3

[0028] Ti 3 AlC 2 Put it into a stainless steel reactor, the total weight of the sample is 1.0g, fill it with nitrogen and seal it, and react mechanically at 300rpm for 6h. Dissolve 15.0g of sodium hydroxide in 10mL of deionized water, cool to room temperature, pass nitrogen gas for 5 minutes, add strong alkali solution into the above reactor, fill with nitrogen again to seal, rotate at 300rpm, and perform mechanochemical reaction for 12 hours. After the above reactor was cooled to room temperature, deionized water was added under nitrogen protection and ice bath. After cooling to room temperature, the mixed solution was centrifuged at 9000 rpm until neutral. Add deionized water to the precipitate and centrifuge at 3500rpm for 5min, take the supernatant, freeze-dry, and finally obtain the mechanochemically prepared Ti 3 C 2 T x .

[0029] Take the mass ratio of 8:1:1, weigh the Ti prepared by the mechanochemistry of Example 3 3 C 2 T x , conductive carbon black, sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com