A kind of production method of high-quality opaque quartz glass ingot

A technology of transparent quartz and glass ingots, which is applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problem that liquid small molecule silicone cannot be uniformly adhered, improve density uniformity and yield, and avoid product accumulation material, increase the effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

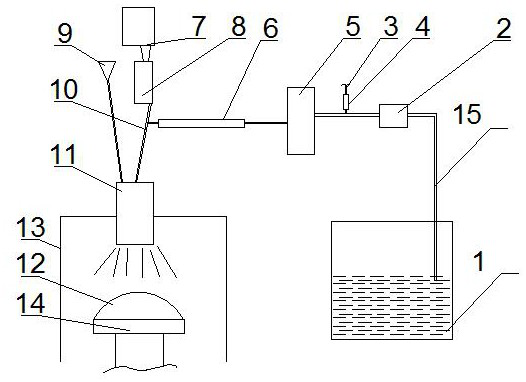

[0049] First select the quartz sand particles with a diameter of 120 meshes as the raw material, and place them in the quartz sand silo 7 of the melting device. Material box 1, organic silicon evaporator 5, feeding pipe 10 and electric heating and heat preservation device 10 are formed; the top of melting furnace 13 is provided with hydrogen-oxygen burner 11, and the top of hydrogen-oxygen burner 11 is provided with quartz sand silo 7, The quartz sand silo 7 is provided with a hydrogen gas source box 8 loaded with quartz sand. The quartz sand silo 7 communicates with the hydrogen gas source box 8 of the quartz sand through the discharge port, and the hydrogen gas source box 8 of the quartz sand passes through the feeding pipe 10. It is communicated with the hydrogen-oxygen burner 11, and the quartz sand-carrying hydrogen gas source box 8 is communicated with the quartz sand-carrying hydrogen gas source at the same time, and the melting furnace 13 below the hydrogen-oxygen burne...

Embodiment 2

[0057] First select the quartz sand particles with a diameter of 140 meshes as the raw material, and place them in the quartz sand silo 7 of the melting device. Material box 1, organic silicon evaporator 5, feeding pipe 10 and electric heating and heat preservation device 10 are formed; the top of melting furnace 13 is provided with hydrogen-oxygen burner 11, and the top of hydrogen-oxygen burner 11 is provided with quartz sand silo 7, The quartz sand silo 7 is provided with a hydrogen gas source box 8 loaded with quartz sand. The quartz sand silo 7 communicates with the hydrogen gas source box 8 of the quartz sand through the discharge port, and the hydrogen gas source box 8 of the quartz sand passes through the feeding pipe 10. It is communicated with the hydrogen-oxygen burner 11, and the quartz sand-carrying hydrogen gas source box 8 is communicated with the quartz sand-carrying hydrogen gas source at the same time, and the melting furnace 13 below the hydrogen-oxygen burne...

Embodiment 3

[0065] First select the quartz sand particles with a diameter of 160 meshes as the raw material, and place them in the quartz sand silo 7 of the melting device. Material box 1, organic silicon evaporator 5, feeding pipe 10 and electric heating and heat preservation device 10 are formed; the top of melting furnace 13 is provided with hydrogen-oxygen burner 11, and the top of hydrogen-oxygen burner 11 is provided with quartz sand silo 7, The quartz sand silo 7 is provided with a hydrogen gas source box 8 loaded with quartz sand. The quartz sand silo 7 communicates with the hydrogen gas source box 8 of the quartz sand through the discharge port, and the hydrogen gas source box 8 of the quartz sand passes through the feeding pipe 10. It is communicated with the hydrogen-oxygen burner 11, and the quartz sand-carrying hydrogen gas source box 8 is communicated with the quartz sand-carrying hydrogen gas source at the same time, and the melting furnace 13 below the hydrogen-oxygen burne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com