Durable dew-blocking-prevention combined-type exhaust gas waste heat utilization device

A flue gas waste heat, combined technology, used in steam generation methods using heat carriers, indirect heat exchangers, climate sustainability, etc., can solve problems such as personnel and property losses, safety hazards, leakage, etc. The effect of corrosion, avoidance of aggregation, and prevention of low temperature condensation of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

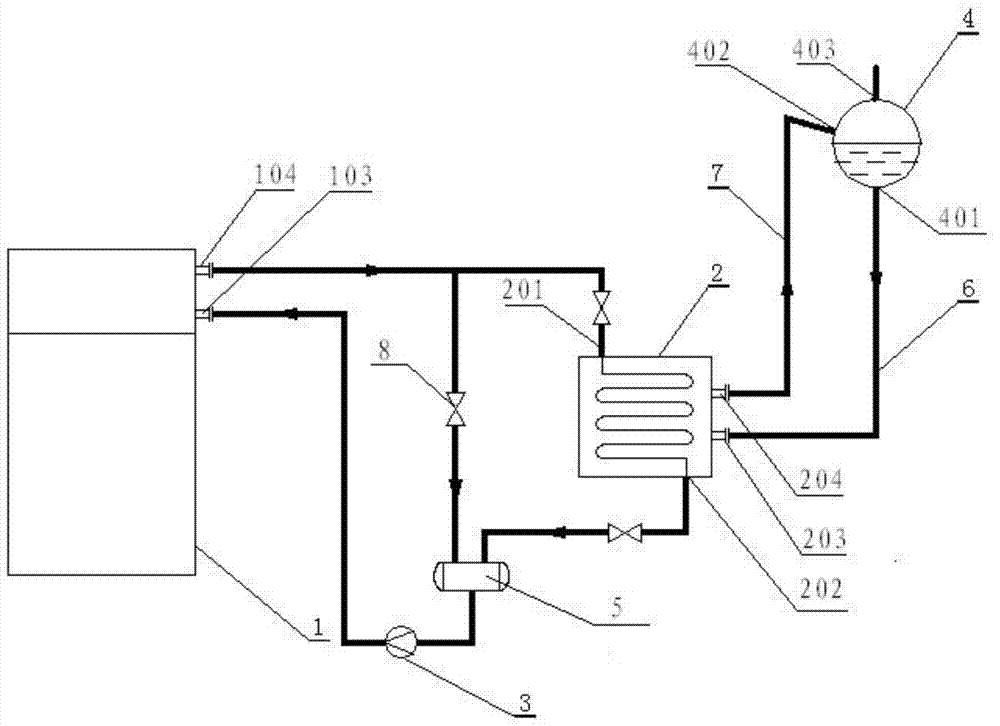

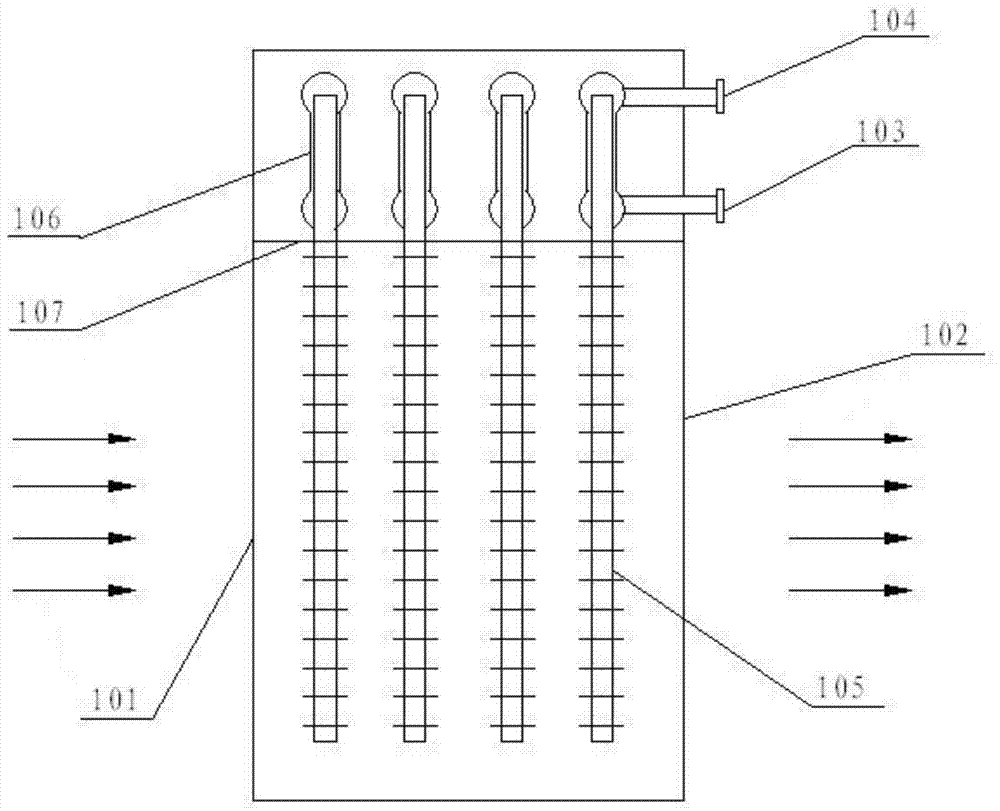

[0031] As shown in the figure, this embodiment provides a durable anti-dew combined flue gas waste heat utilization device, including heat transfer oil casing heat pipe heat exchanger 1, tube heat exchanger 2, heat transfer oil pump 3, steam drum 4 and The expansion tank 5, the lower end of the heat transfer oil jacketed heat pipe heat exchanger 1 is provided with a flue gas inlet 101 and the flue gas outlet 102, and the upper end of the heat transfer oil jacketed heat pipe heat exchanger 1 is provided with a heat transfer oil inlet I 103 and a heat transfer oil outlet I 104, The heat transfer oil inlet I103 is connected to the outlet of the heat transfer oil pump 3 , and the inlet of the heat transfer oil pump 3 is connected to the outlet of the expansion tank 5 .

[0032] Tubular heat exchanger 2 is divided into hot side and cold side. The hot side of tube heat exchanger 2 is provided with heat transfer oil inlet II 201 and heat transfer oil outlet II 202. The cold side of tu...

Embodiment 2

[0036] This embodiment is used in the production process of titanium dioxide, and the calcination process will produce a large amount of tail gas for recycling. This embodiment uses the same equipment as in Example 1, and the calcination process produces a large amount of tail gas from the heat transfer oil casing. The flue gas inlet 101 of the type heat pipe heat exchanger 1 enters, and is discharged from the flue gas outlet 102 after the countercurrent heat exchange occurs with the heat pipe working fluid in the heat conduction oil jacketed heat pipe heat exchanger 1 .

[0037] The working process of this embodiment is: after the calcination process produces a large amount of tail flue gas through the heat-conducting oil casing heat pipe heat exchanger 1, the heat of the medium and high temperature flue gas is transferred to the tube heat exchanger 2 by means of heat transfer. Oil, after the oil temperature rises, the heat is transferred to the water in the steam drum 4 by me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com