Anti-cracking gypsum-based plastering mortar and preparation method thereof

A plaster mortar and gypsum-based technology, which is applied in the field of building gypsum-based thermal insulation materials, can solve problems such as the bottleneck of toughening and crack resistance effects, and achieve the effects of improving deformation resistance, reducing dry shrinkage, and strengthening anti-deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

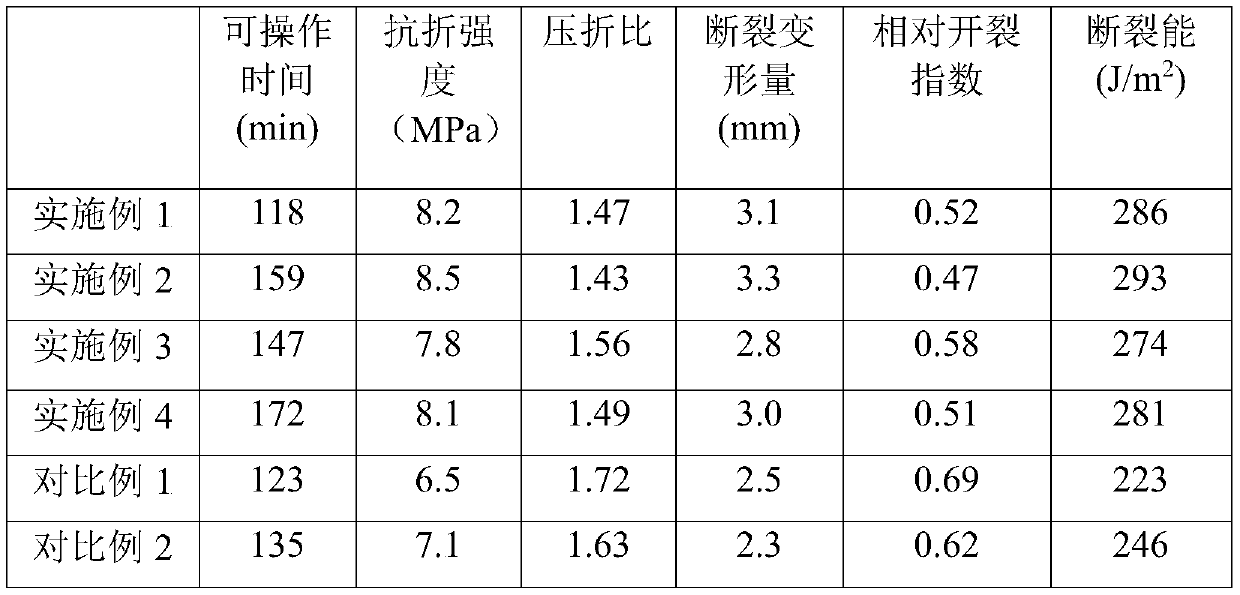

Examples

Embodiment 1

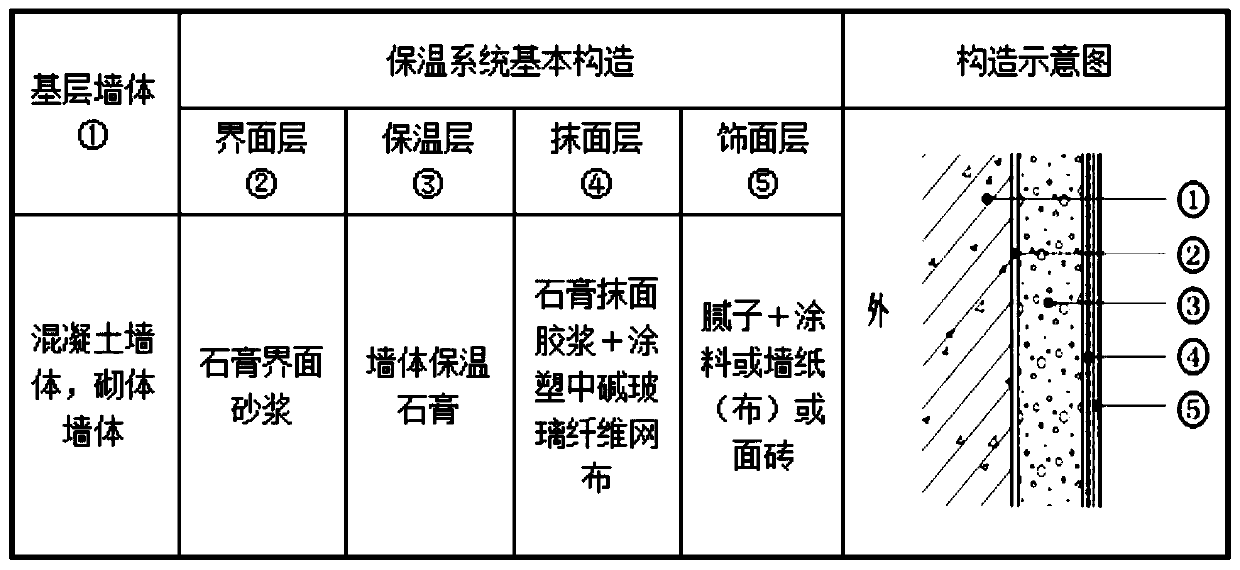

[0024] figure 1 The basic structure of the building's exterior wall interior insulation system is a gypsum-based insulation material. In order to ensure the uniformity and compatibility of the materials of the whole system, a new type of building insulation system is established on the basis of replacing cement base with gypsum base. This invention develops a crack-resistant gypsum-based plaster mortar for gypsum-based thermal insulation. The plastering layer of the thermal insulation system of the external wall of the building.

[0025] Taking 100kg of building plaster used for preparing the anti-cracking type gypsum-based plaster mortar of the present invention as an example, the raw materials used and their quality are as follows:

[0026] Construction plaster 100kg

[0027] 41kg of water

[0028] Polypropylene fiber 0.1kg

[0029] Glass fiber 0.2kg

[0030] Silane coupling agent 0.3kg

[0031] Adhesive 0.2kg

[0032] Water retaining agent 0.3kg

[0033] Water reduc...

Embodiment 2

[0042] Taking 100kg of building plaster used for preparing the anti-cracking type gypsum-based plaster mortar of the present invention as an example, the raw materials used and their quality are as follows:

[0043] Construction plaster 100kg

[0044] 40kg of water

[0045] Polypropylene fiber 0.1kg

[0046] Glass fiber 0.2kg

[0047] Silane coupling agent 0.5kg

[0048] Adhesive 0.2kg

[0049] Water retaining agent 0.3kg

[0050] Water reducer 0.5kg

[0051] Retarder 0.3kg;

[0052] The specification and preparation method of the above-mentioned raw materials are the same as in Example 1.

Embodiment 3

[0054] Taking 100kg of building plaster used for preparing the anti-cracking type gypsum-based plaster mortar of the present invention as an example, the raw materials used and their quality are as follows:

[0055] Construction plaster 100kg

[0056] 41kg of water

[0057] Polypropylene fiber 0.2kg

[0058] Glass fiber 0.1kg

[0059] Silane coupling agent 0.4kg

[0060] Adhesive 0.3kg

[0061] Water retaining agent 0.4kg

[0062] Water reducer 0.3kg

[0063] Retarder 0.3kg;

[0064] The specification and preparation method of the above-mentioned raw materials are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com