Concrete containing coal-to-liquid (CTL) coarse slag and preparation method of concrete

A coal-to-oil and concrete technology, applied in the direction of cement production, etc., can solve the problems of complex processing process and high cost, and achieve the effects of reasonable compatibility, reduction of preparation cost, and reduction of cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Preparation of gelling material

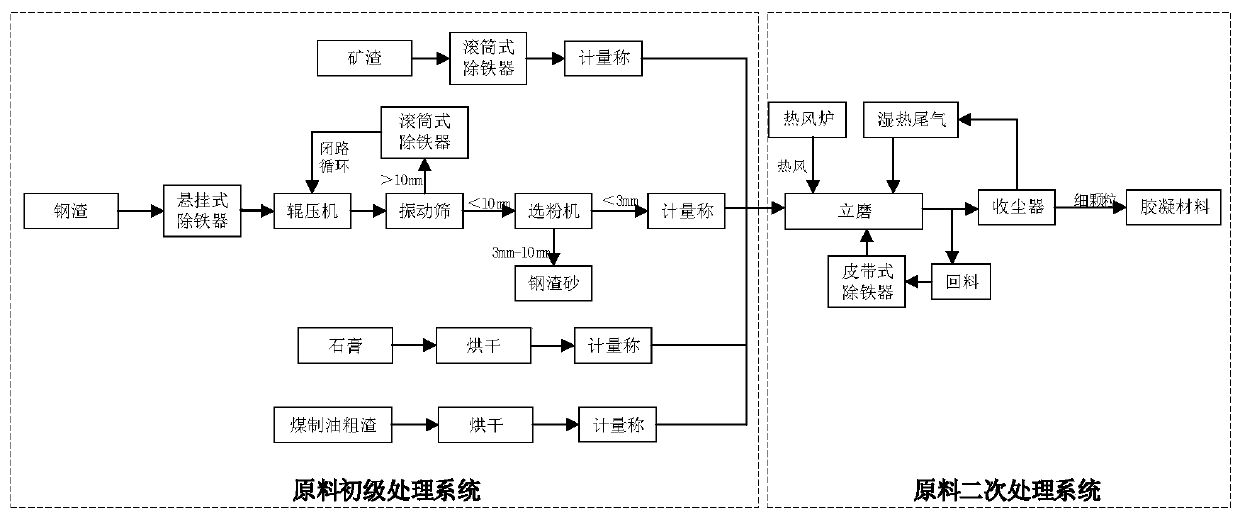

[0050] (1.1) Preparation of steel slag grains and steel slag sand

[0051] Primary crushing and pre-removal of steel slag raw materials: The raw materials of converter steel slag are fed and pre-removed with a hanging iron remover. The steel slag after pre-removed iron enters the roller press for primary crushing, and then enters the vibrating screen for screening. After sieving, coarse particles I and fine particles I are produced. The particle size of the coarse particle I is 15mm, and the particle size of the fine particle I is 10mm; the coarse particle I returns to the roller press after being removed by the drum type iron remover to continue crushing, forming a closed loop; the fine particle I is separated by the powder separator, and prepared Steel slag sand and fine particle II are obtained, the particle size of the steel slag sand is 5 mm, and the particle size of the fine particle II is 2.8 mm; the fine particle II is the s...

Embodiment 2

[0070] 1. Preparation of gelling material

[0071] (1.1) Preparation of steel slag grains and steel slag sand

[0072] Primary crushing and pre-removal of steel slag raw materials: The raw material of electric furnace steel slag is fed, and pre-removed by hanging iron remover. The steel slag after pre-removed iron enters the roller press for primary crushing, and then enters the vibrating screen for screening. After sieving, coarse particles I and fine particles I are produced, the particle size of coarse particles I is 10mm, and the particle size of fine particles I is 5mm; coarse particles I return to the roller press after iron removal by the drum type iron remover to continue crushing, forming a closed loop ; After the fine particle I is selected by the powder separator, steel slag sand and fine particle II are formed. The particle size of the steel slag sand is 3mm, and the particle size of the fine particle II is 2mm; the fine particle II is the steel slag particle.

[...

Embodiment 3

[0091] 1. Preparation of gelling material

[0092] (1.1) Preparation of steel slag grains and steel slag sand

[0093] Primary crushing and pre-removal of steel slag raw materials: The raw material of electric furnace steel slag is fed, and pre-removed by hanging iron remover. The steel slag after pre-removed iron enters the roller press for primary crushing, and then enters the vibrating screen for screening. After sieving, coarse particles I and fine particles I are produced, the particle size of coarse particles I is 10mm, and the particle size of fine particles I is 5mm; coarse particles I return to the roller press after iron removal by the drum type iron remover to continue crushing, forming a closed loop ; After the fine particle I is selected by the powder separator, steel slag sand and fine particle II are formed. The particle size of the steel slag sand is 3mm, and the particle size of the fine particle II is 2mm; the fine particle II is the steel slag particle.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com