Method for determining harmful elements in iron ore

A technology of harmful elements and determination methods, which is applied in the direction of measuring devices, test sample preparation, instruments, etc., can solve the problems of cumbersome workload and inaccurate determination of trace elements, etc., and achieve the goal of overcoming mutual influence, good determination stability, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

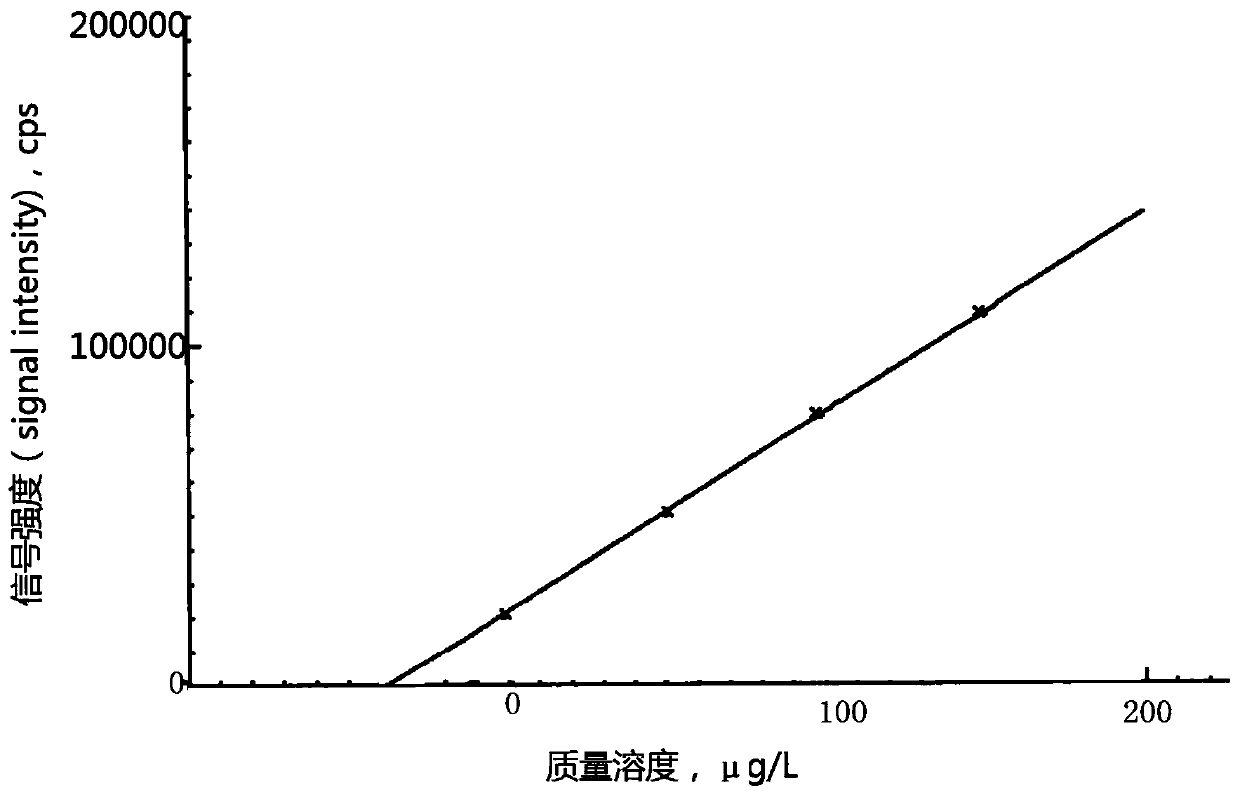

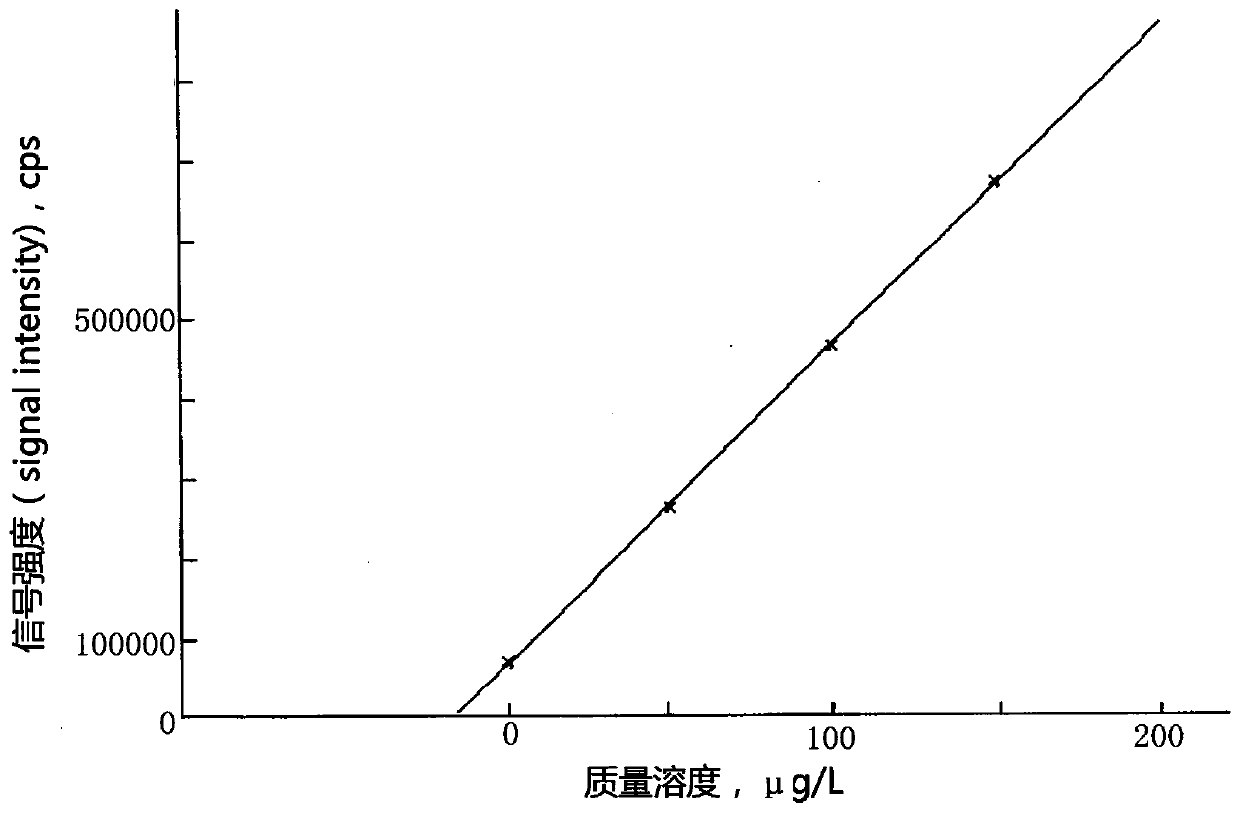

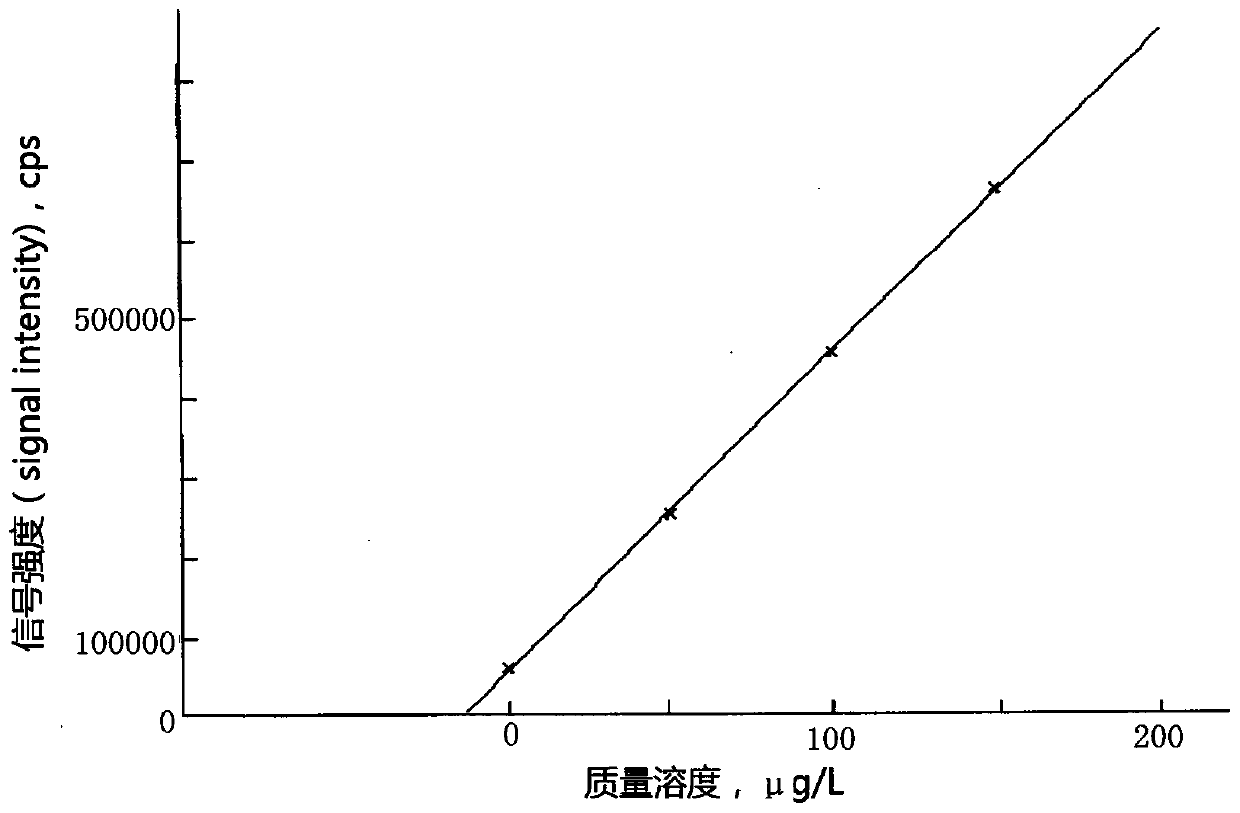

Image

Examples

Embodiment 1

[0038] Step 1. Pretreatment of the iron ore sample to be tested: the iron ore to be tested is the standard product GSBH3006-97, and its content of Na, K, Pb, and Zn is 0.0378%, 0.0332%, 0.0015%, and 0.0093% and accurately weighed Put 0.1g of the iron ore sample to be tested in a microwave digestion tank, the first step: add 1mL of hydrochloric acid, 6mL of nitric acid, and 0.02g of graphite in sequence; place the microwave digestion tank in a microwave digestion instrument, turn on the microwave digestion It is set as: power is 1600W, temperature is 190°C, heating program is 2min to 190°C, constant temperature is 5min to start cooling; the second step: add 3mL of nitric acid and 1mL of hydrofluoric acid in sequence, and the concentration of nitric acid added in the second step If the concentration of nitric acid is lower than that in the first step, place the microwave digestion tank in the microwave digestion instrument, turn on the microwave digestion instrument, set the prog...

Embodiment 2

[0047] Step 1. Pretreatment of the iron ore sample to be tested: accurately weigh 0.1 g of the iron ore sample to be tested and place it in a microwave digestion tank. The first step: add 1 mL of hydrochloric acid, 6 mL of nitric acid, and 0.02 g of graphite in sequence; Put the tank in the microwave digestion apparatus, turn on the microwave digestion apparatus, set the program as follows: power is 1600W, temperature is 190°C, the heating program is 2min to 190°C, constant temperature 5min to start cooling; the second step: add nitric acid in sequence 3mL, 1mL hydrofluoric acid, and the concentration of nitric acid added in the second step is lower than the concentration of nitric acid added in the first step, put the microwave digestion tank in the microwave digestion instrument, turn on the microwave digestion instrument, and set the program as: power The temperature is 1000W, the temperature is 120°C, the heating program is 5min to 120°C, and the constant temperature is 15m...

Embodiment 3

[0056] Step 1. Pretreatment of the iron ore sample to be tested: accurately weigh 0.1 g of the iron ore sample to be tested and place it in a microwave digestion tank. Step 1: Add 1 mL of hydrochloric acid, 4 mL of nitric acid, 0.03 g of graphite, and nano-ceramic particles 0.02g; put the microwave digestion tank in the microwave digestion instrument, turn on the microwave digestion instrument, set the program as follows: power 1600W, temperature 190°C, heating program: 2min to 190°C, constant temperature 5min to start cooling; second Step 1: Add 2 mL of nitric acid and 1 mL of hydrofluoric acid in sequence, and the concentration of nitric acid added in the second step is lower than that of the first step. Place the microwave digestion tank in the microwave digestion apparatus, turn on the microwave digestion apparatus, and The program is set as follows: the power is 1000W, the temperature is 120°C, the temperature rise program is 5min to 120°C, the temperature is constant for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com