Ultra-wideband intermediate infrared band perfect wave absorber and preparation method thereof

An infrared band and ultra-broadband technology, applied in the field of mid-infrared perfect absorber and its preparation, can solve the problems of narrow absorption band, low efficiency, narrow absorption bandwidth, etc., and achieve the effect of low cost and high-efficiency absorbing response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

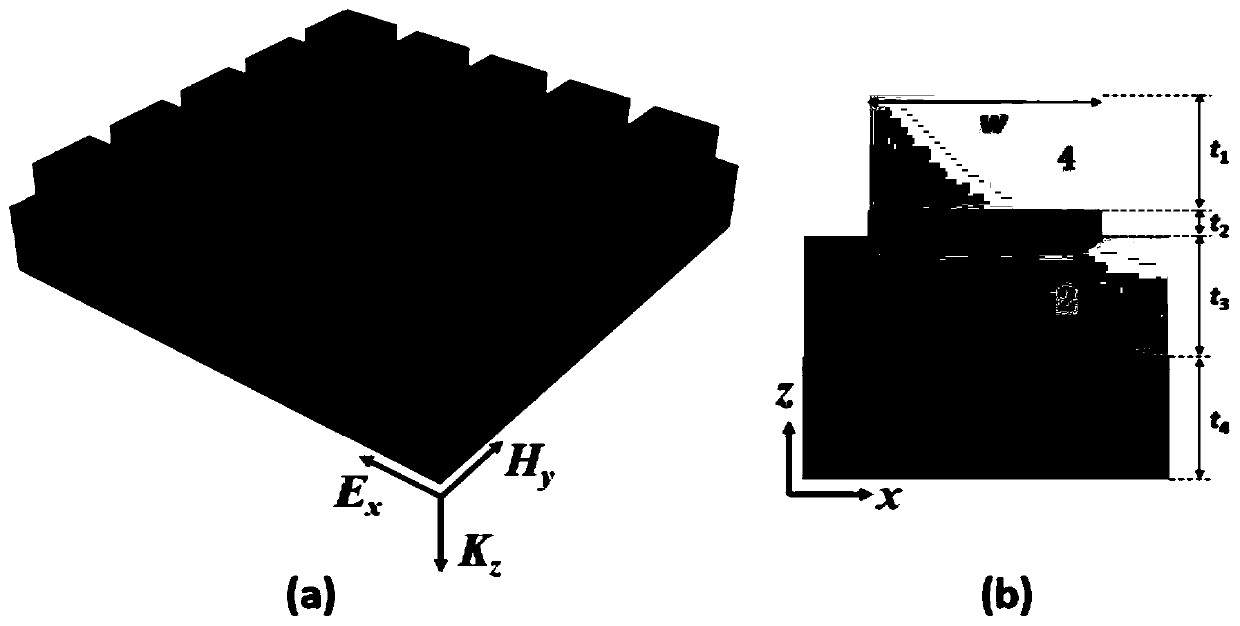

[0048] The ultra-broadband mid-infrared band perfect wave absorber in this embodiment adopts two kinds of materials, chromium and alumina. First, a layer of chromium with a thickness of 150 nanometers is sequentially deposited on the substrate silica glass sheet by physical vacuum coating method. film, a layer of aluminum oxide film with a thickness of 170 nm, a layer of chromium film with a thickness of 15 nm, and a layer of aluminum oxide film with a thickness of 180 nm; The dielectric / metal nanocubes are prepared by etching technology as a periodic periodic array, the array period (P) is 250 nanometers, the side length (W) of the nanocubes is 220 nanometers, and the thickness of the flat metal film (t 4) is 150 nm, and the flat dielectric film thickness (t 3 ) is 170 nm, the thickness of the metal nanocube (t 2 ) is 15 nm, and the thickness of the dielectric nanocube (t 1 ) is 180 nm. The surrounding environment is air.

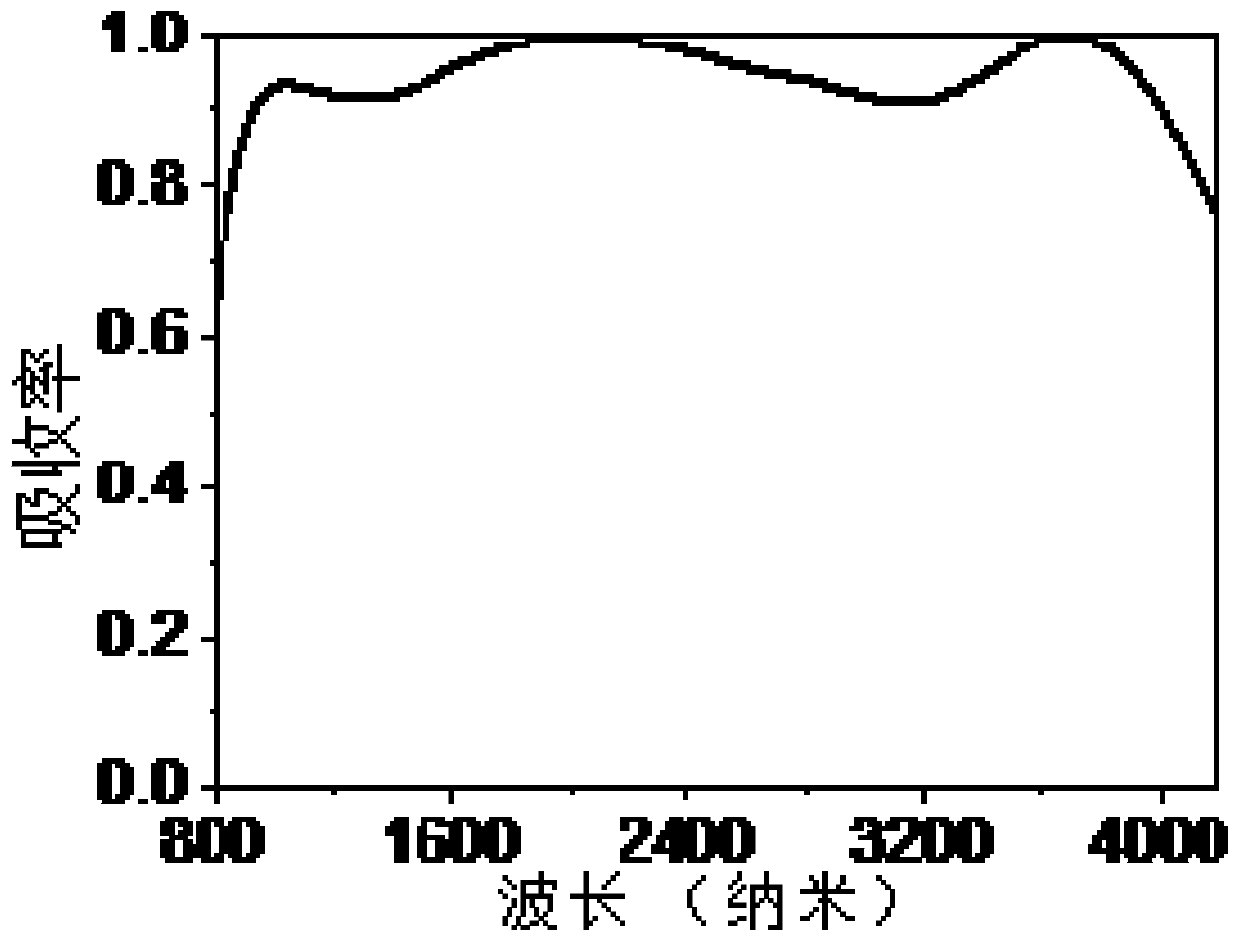

[0049] Such as figure 2 As shown, from the nea...

Embodiment 2

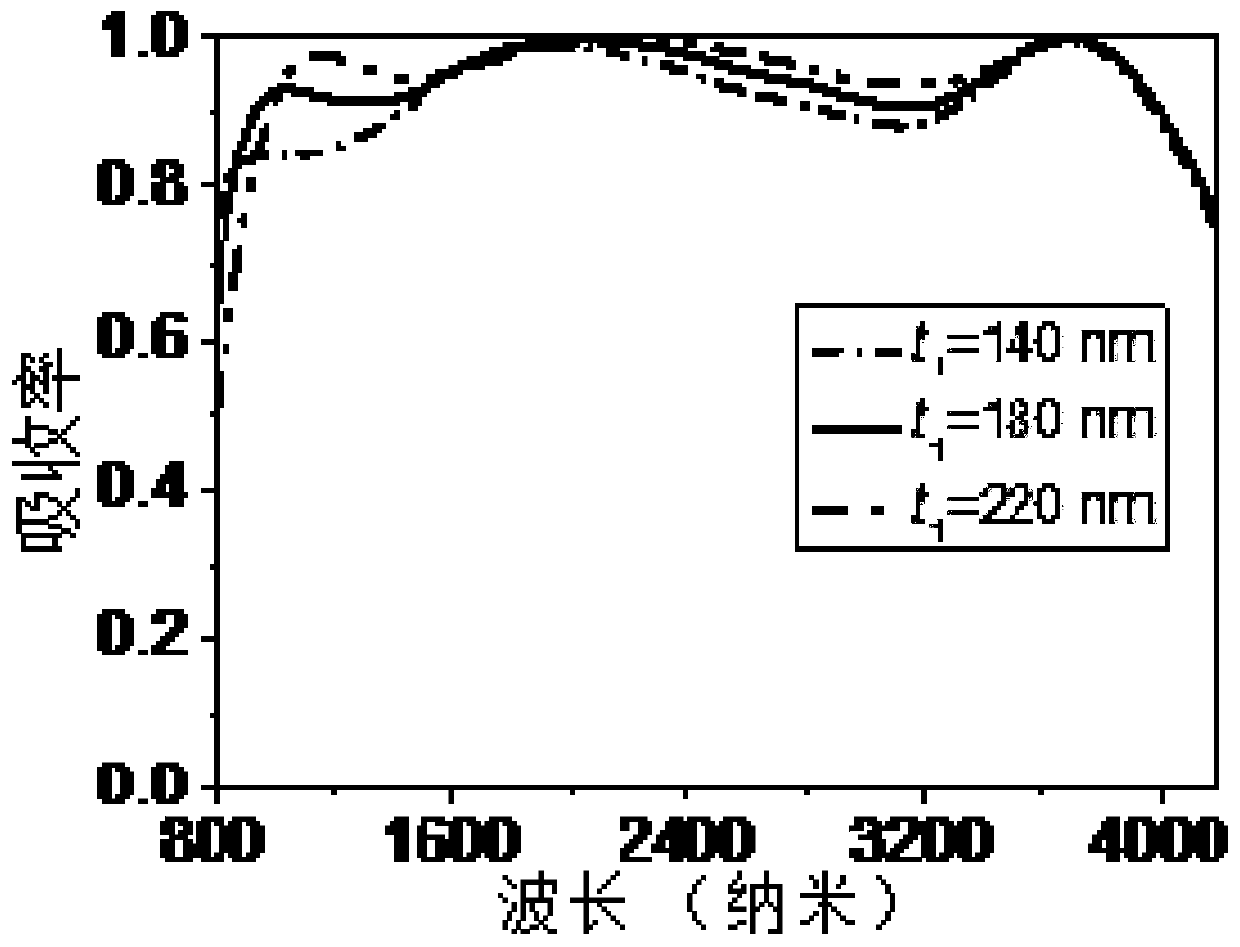

[0051] The top layer of the ultra-broadband mid-infrared band perfect wave absorber in this embodiment is a dielectric alumina nanocube with a thickness of 140 nanometers, and other parameters are the same as those in Embodiment 1. To test, you can get as image 3 The corresponding absorption spectra are shown.

Embodiment 3

[0053] The top layer of the ultra-broadband mid-infrared band perfect wave absorber in this embodiment is a dielectric alumina nanocube with a thickness of 180 nanometers, and other parameters are the same as those in Embodiment 1. To test, you can get as image 3 As shown in the corresponding absorption spectrum graph, the absorber should absorb more than 90% of the broadband up to 3059 nm, from 939 nm to 3998 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com