Compound, coating composition comprising same and organic light-emitting device

A technology for organic light-emitting devices and compounds, applied in the fields of compounds, coating compositions containing them, and organic light-emitting devices, capable of solving problems such as low LUMO energy levels, achieving high solubility, improving light efficiency, and reducing driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

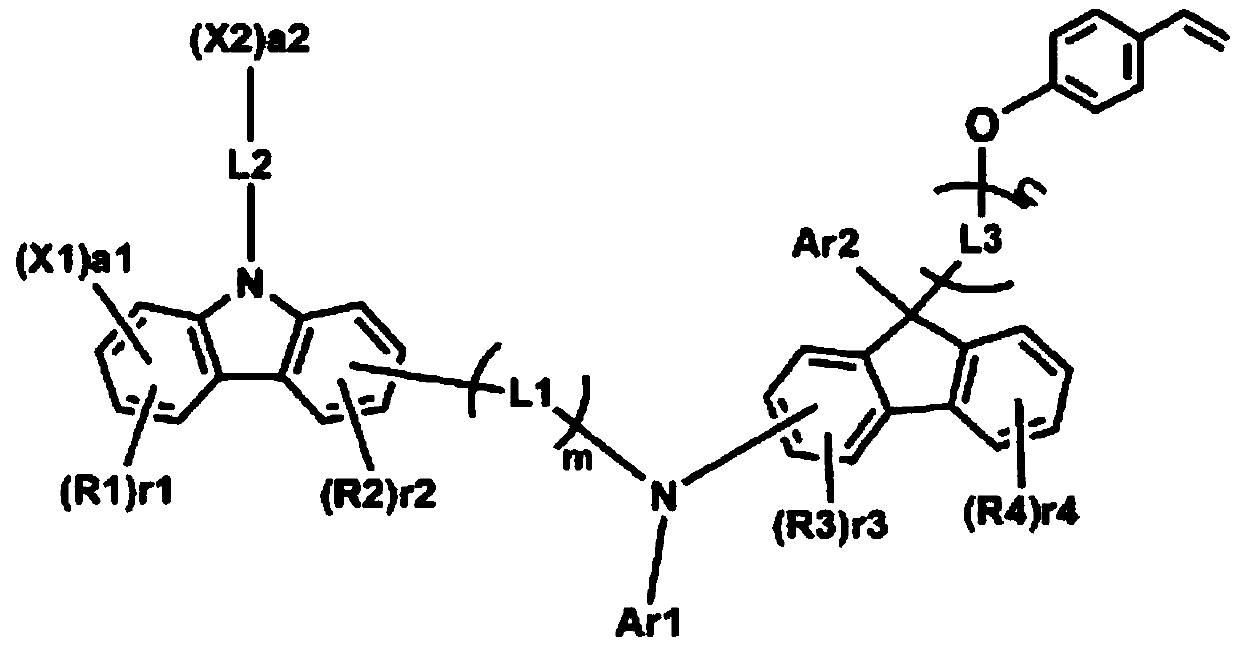

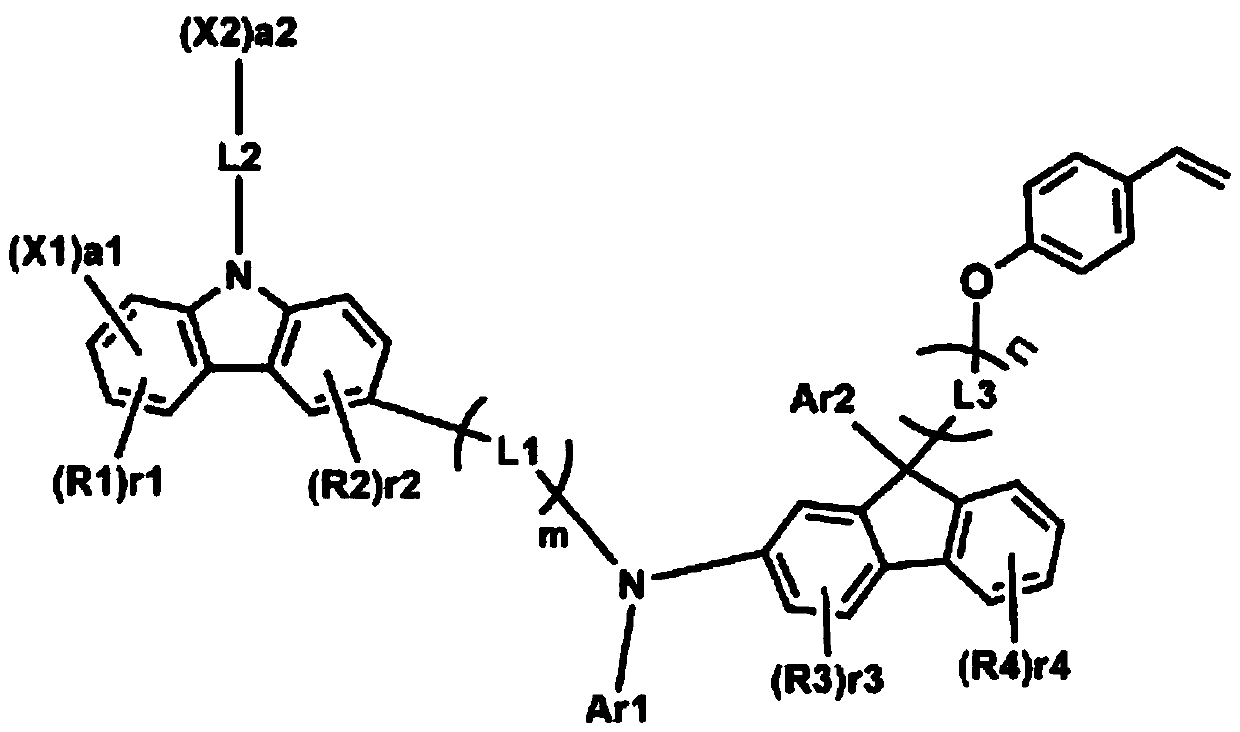

Method used

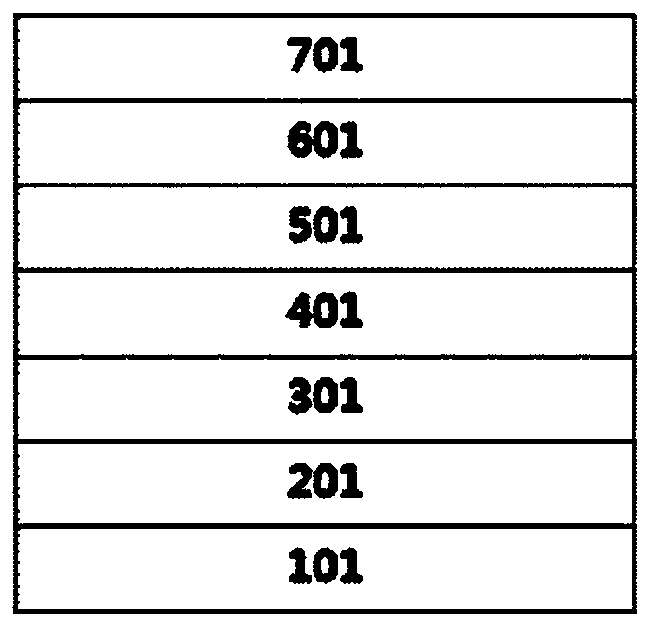

Image

Examples

Embodiment approach

[0203] Hereinafter, the specification will be described in detail with reference to the examples to specifically describe the specification. However, the embodiments according to the present specification can be modified into various forms, and the scope of the present specification should not be construed as being limited to the following embodiments. The embodiments of this specification are provided to more fully describe this specification to those skilled in the art.

preparation example 1-1

[0205] -Preparation of Compound 1

[0206] Preparation of Intermediate I-1

[0207]

[0208] Filled with 3-bromo-9-phenyl-9H-carbazole (16.11g, 50.0mmol), 4-(4,4,5,5-tetramethyl-1,3,2-dioxaborin -2-yl) aniline (10.95g, 50.0mmol), tetrakis (triphenylphosphine) palladium (0) (1.73g, 1.5mmol) and K 2 CO 3 (20.23g, 100.0mmol) in the flask, introduce THF / H 2 O (v / v=3 / 1) (800ml), and the resultant was heated under N at 80°C 2 Stirring was continued for 16 hours. After allowing the reaction to end, the reaction solution was cooled, and then the organic layer was extracted using an extraction flask. with MgSO 4 The organic layer was dried, and the organic solvent was removed using a rotary vacuum evaporator, and then the residue was subjected to column purification to obtain I-1 (10.2 g, yield 51%, HPLC purity 99.4%).

[0209] Preparation of Intermediate I-2

[0210]

[0211] Toluene was introduced into a flask containing 1-1 (3.2 g, 10.0 mmol), bromobenzene (1.57 g,...

Embodiment 1

[0372] deposited on it with a thickness of The indium tin oxide (ITO) glass substrate as a thin film was placed in distilled water dissolved with detergent and cleaned ultrasonically. After cleaning the ITO for 30 minutes, ultrasonic cleaning was repeated twice for 10 minutes using distilled water. After completion of rinsing with distilled water, the substrates were ultrasonically cleaned with isopropanol and acetone solvents for 30 minutes each, dried, and then transferred to a glove box.

[0373] On the transparent ITO electrode prepared as above, a coating composition mixed with compound 1 (20 mg), chemical formula D-1 (1 mg) and toluene (1 mg) was formed by spin coating to form a thickness of The hole injection layer was made and the coating composition was allowed to cure in air on a hot plate for 1 hour. After that, the resultant was transferred to a vacuum deposition apparatus, and a hole transport layer was formed on the hole injection layer by vacuum deposition o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com