A rare earth doped titanium dioxide modified polyvinyl chloride composite material and its preparation method

A titanium dioxide and rare earth doping technology, which is applied in the field of polymer composite material preparation, can solve the problems of large difference in surface properties, loss of nanoscale, difficulty in uniform dispersion, etc., to increase interface bonding force, facilitate dispersion, and the preparation method is simple and practical Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

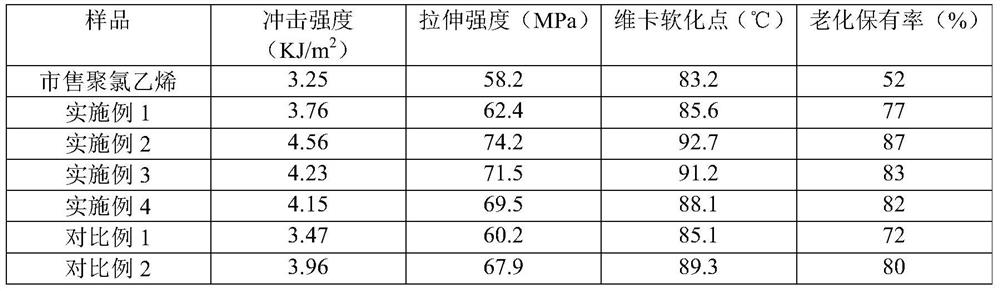

Examples

Embodiment 1

[0040] This embodiment provides a method for preparing a rare earth-doped titanium dioxide-modified polyvinyl chloride composite material, which includes the following steps:

[0041] Preparation of rare earth doped titanium dioxide powder:

[0042] A. Dissolve 10ml of butyl titanate in 10ml of ethanol, stir and disperse evenly to obtain A solution;

[0043] B. Weigh again 0.5g lanthanum oxide and disperse it in 20mL ethanol solution, obtain B solution after fully ultrasonic stirring and filtering;

[0044] C. Ultrasonic stirring, continuously and slowly add 20mL of B solution to A solution at room temperature, and then put it in a dark place to age for 24 hours to obtain a rare earth-doped titanium dioxide sol, wherein the dropping rate is 0.01ml per second;

[0045] D. After drying and molding, place it in a muffle furnace, set the temperature at 300°C for calcination for 4 hours, and get the rare earth doped titanium dioxide powder after physical grinding;

[0046] Prepar...

Embodiment 2

[0057]This embodiment provides a method for preparing a rare earth-doped titanium dioxide-modified polyvinyl chloride composite material, which includes the following steps:

[0058] Preparation of rare earth doped titanium dioxide powder:

[0059] A. Dissolve 10ml of isopropyl titanate in 100ml of ethanol, stir and disperse evenly to obtain A solution;

[0060] B. Take again 27.5g of cerium oxide and disperse it in 1100mL ethanol solution, obtain B solution after fully ultrasonic stirring and filtering;

[0061] C. Stir ultrasonically, continuously and slowly add 1100mL of solution B to solution A at room temperature, and then put it in the dark for 168h to obtain the rare earth-doped titanium dioxide sol, wherein the dropping rate is 1ml per second;

[0062] D. After drying and molding, put it in a muffle furnace, set the temperature at 600 ° C for 1 hour, and physically grind it to get the rare earth doped titanium dioxide powder;

[0063] Preparation of rare earth-doped ...

Embodiment 3

[0074] This embodiment provides a method for preparing a rare earth-doped titanium dioxide-modified polyvinyl chloride composite material, which includes the following steps:

[0075] Preparation of rare earth doped titanium dioxide powder:

[0076] A. Dissolve 20ml of butyl titanate in 50ml of methanol, stir and disperse evenly to obtain A solution;

[0077] B. Take again by weighing 8.75g lanthanum oxide and disperse in 350mL ethanol solution, obtain B solution after fully ultrasonic stirring and filtering;

[0078] C. Ultrasonic stirring, continuously and slowly add 350mL of B solution to A solution at room temperature, and then put it in the dark for 72 hours to obtain the rare earth-doped titanium dioxide sol, wherein the dropping rate is 0.5ml per second;

[0079] D. After drying and molding, put it in a muffle furnace, set the temperature at 400 ° C for 3 hours and calcinate for 3 hours, and then get the rare earth doped titanium dioxide powder after physical grinding;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com