Preparation method of caramelized sweet and caramelized aroma type cigar tobacco

A technology of cigar tobacco leaves and burnt aroma, which is applied in the fields of tobacco, tobacco treatment, application, etc. It can solve the problems of not obvious sweetening effect, achieve the effect of improving appearance, promoting exchange, and the color of tobacco leaves is reddish brown and shiny

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

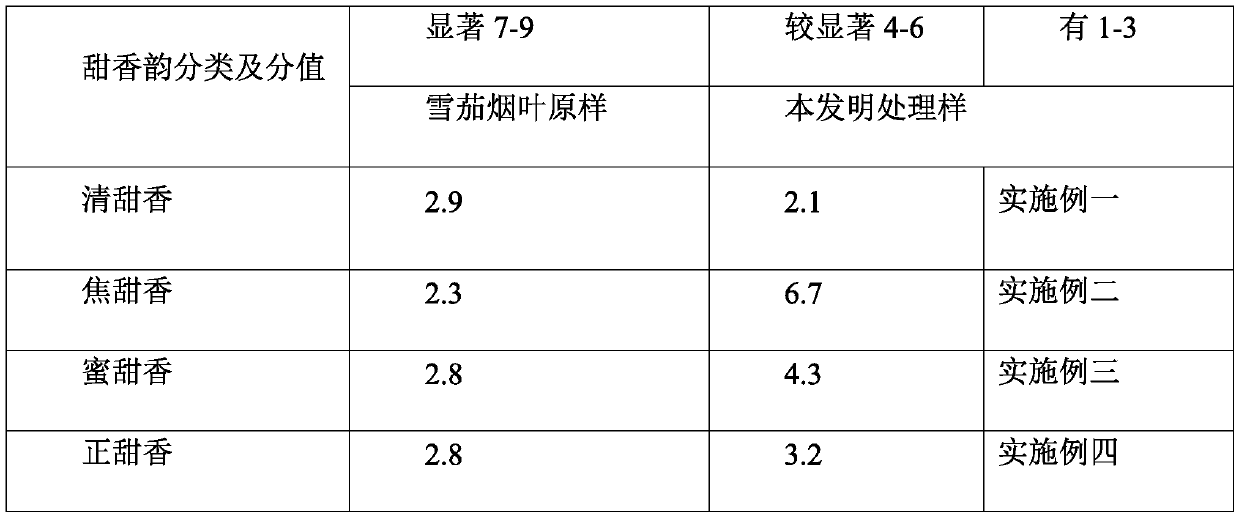

Embodiment 1

[0022] Use an iron pan to add 10g glycerin to heat. After the glycerin boils, add 150g white sugar and 0.1g potassium citrate to start frying. Stir fry continuously. After the white sugar is caramelized and browned, add 9.84Kg mineral water rich in magnesium salt and boil. After the water is boiled, immerse the Sichuan Deyang Shifang GH-1 second-grade tobacco leaves for cooking, boil for about 45 seconds, take them out, and use a hanging rack to dry to the appropriate moisture, that is, the sweet burnt used in cigar recipes is produced. Flavored cigar tobacco.

Embodiment 2

[0024] Add 10g of glycerin to an iron pan and heat it. After the glycerin boils, add 250g of brown sugar and 0.1g of potassium citrate to start frying. Stir fry continuously. After the brown sugar is caramelized and browned, add 9.74Kg of mineral water rich in magnesium salts and boil. After the water boils, immerse the Sichuan Deyang Shifang GH-1 second-grade tobacco leaves for cooking, boil for about 120 seconds, take them out, and hang them on a hanging rack to dry to the appropriate moisture, that is, the sweet burnt used in cigar recipes is produced. Flavored cigar tobacco.

Embodiment 3

[0026] Add 10g of glycerin to an iron pot and heat it. After the glycerin boils, add 150g of rock sugar and 0.1g of potassium citrate to start frying. Stir continuously. After the rock sugar is caramelized and browned, add 9.84Kg of mineral water rich in magnesium salts to cook. After the water boils, immerse the Sichuan Deyang Shifang GH-1 second-grade tobacco leaves for cooking, boil for about 45 seconds, take them out, and hang them on a drying rack until the moisture is suitable, and then the burnt-sweet burnt-flavor type used in cigar recipes is produced. Cigar tobacco leaves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com