Heavy metal ion adsorbent and preparation method and application thereof

A technology of heavy metal ions and adsorbents, applied in alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as difficult treatment, secondary damage to water environment, etc., and achieve good repeatability and stability , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a heavy metal ion adsorbent (APTES@diatomite), and the preparation method of the heavy metal ion adsorbent is as follows:

[0047] (1) Add 1 g of diatomite to 100 mL of 0.5mol / L NaOH solution, stir at room temperature for 1 hour, wash and dry to obtain surface-activated diatomite;

[0048] (2) Add the surface-activated diatomite into 50ml ethanol solution, stir at room temperature for 3 minutes, and ultrasonically clean for 3 minutes to obtain a suspension of diatomite;

[0049] (3) Add 0.86mL of 3-aminopropyltriethoxysilane dropwise into the diatomaceous earth suspension, and use acetic acid (CH 3 COOH) to adjust the pH of the system to 6, stir and react in a water bath at 40°C for 24 hours, then filter with suction, wash with ethanol and deionized water three times, and dry.

[0050] The performance detection result of described heavy metal ion adsorbent is as follows:

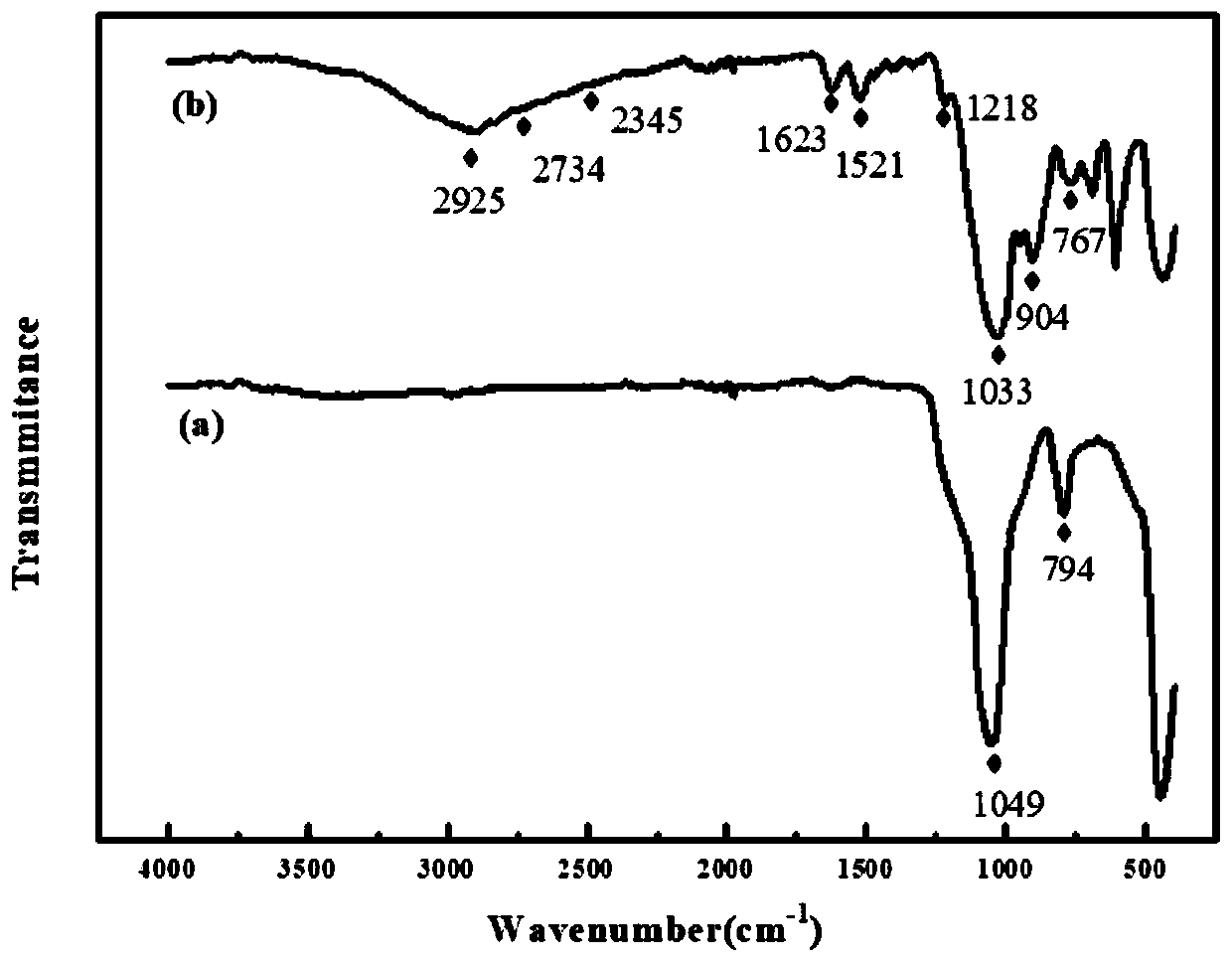

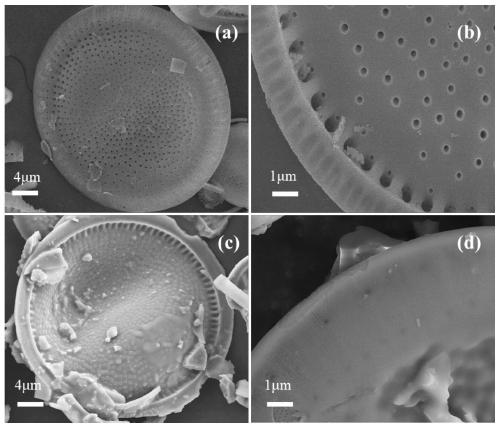

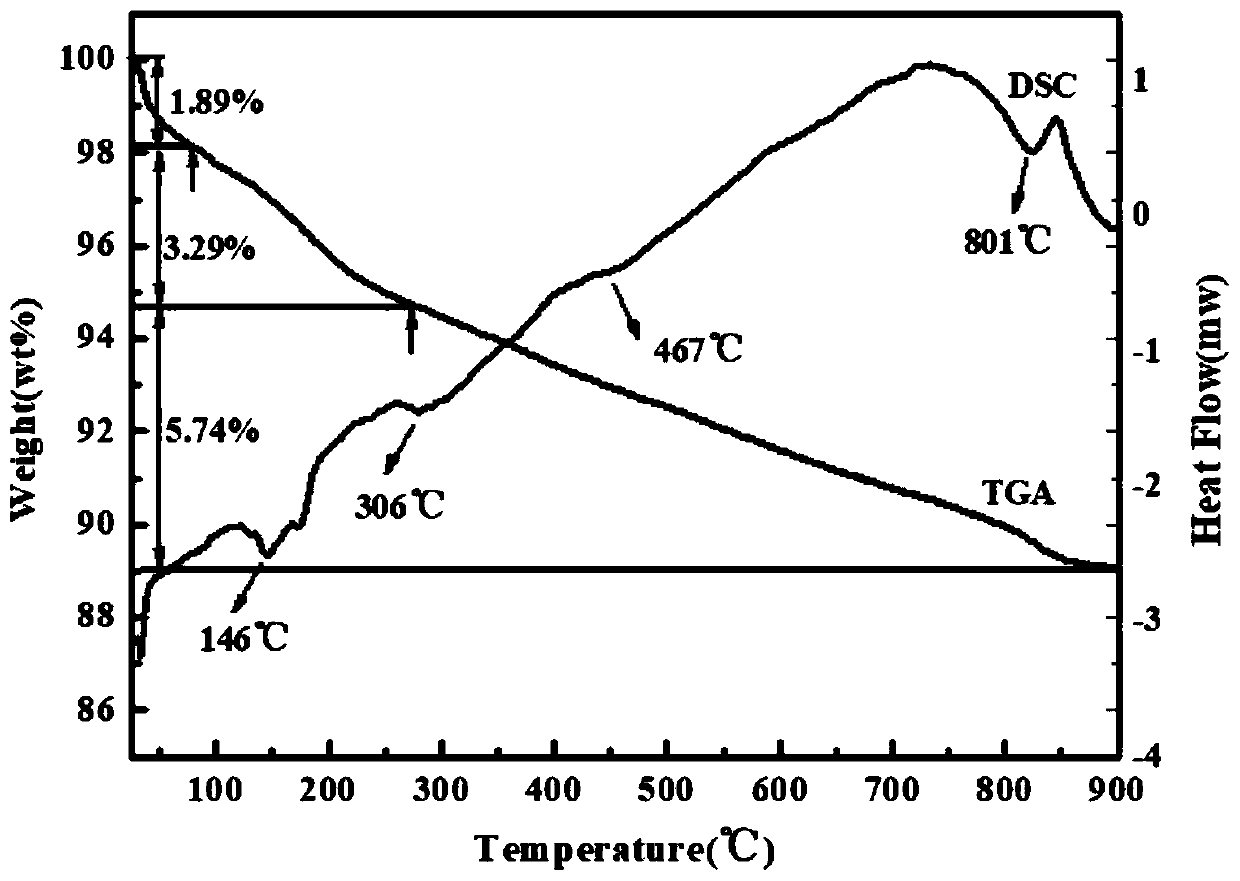

[0051](1) FT-IR image of diatomite and heavy metal ion adsorbent figur...

Embodiment 2

[0056] This embodiment provides a heavy metal ion adsorbent (APTES@diatomite), and the preparation method of the heavy metal ion adsorbent is as follows:

[0057] (1) Add 1 g of diatomite to 100 mL of 0.5mol / L NaOH solution, stir at room temperature for 1 hour, wash and dry to obtain surface-activated diatomite;

[0058] (2) Add the surface-activated diatomite into 50ml ethanol solution, stir at room temperature for 3 minutes, and ultrasonically clean for 3 minutes to obtain a suspension of diatomite;

[0059] (3) Add 1.72 mL of 3-aminopropyltriethoxysilane dropwise into the diatomaceous earth suspension, and use acetic acid (CH 3 COOH) to adjust the pH of the system to 6, reflux and stir at 80°C for 12 hours, filter with suction, wash with ethanol and deionized water three times, and dry.

[0060] Depend on Figure 4 It can be seen that the adsorption capacity of the heavy metal ion adsorbent for Pb(II) is 72.54 mg / g, which is greatly improved compared with diatomite.

Embodiment 3

[0062] This embodiment provides a heavy metal ion adsorbent (APTES@diatomite), and the preparation method of the heavy metal ion adsorbent is as follows:

[0063] (1) Add 1 g of diatomite to 100 mL of 0.5mol / L NaOH solution, stir at room temperature for 1 hour, wash and dry to obtain surface-activated diatomite;

[0064] (2) Add the surface-activated diatomite to 50 mL of toluene solution, stir at room temperature for 3 minutes, and ultrasonically clean for 3 minutes to obtain a suspension of diatomite;

[0065] (3) Add 0.86mL of 3-aminopropyltriethoxysilane dropwise to the diatomaceous earth suspension, use hydrochloric acid (HCl) to adjust the pH of the system to 6, reflux and stir at 80°C for 12 hours, then suction filter, Wash three times with ethanol and deionized water respectively, and dry.

[0066] Depend on Figure 4 It can be seen that the adsorption capacity of the heavy metal ion adsorbent for Pb(II) is 57.6 mg / g, which is greatly improved compared with diatomite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com