Composite photocatalyst DyVO4/g-C3N4B, preparation and application thereof

A catalyst, composite light technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] According to a second aspect of the present invention, a method for preparing a composite photocatalyst is provided, comprising the steps of:

[0030] Step 1, preparing boron-doped graphitic carbon nitride.

[0031] Wherein, step 1 includes the following steps:

[0032] Step 1-1, dissolving the carbon nitrogen source and the boron source in the dispersant and mixing them evenly;

[0033] Step 1-2, remove dispersant;

[0034] Step 1-3, roasting and post-processing to obtain boron-doped graphitic carbon nitride.

[0035] in,

[0036] Step 1-1 middle,

[0037] The carbon-nitrogen source is a low molecular weight nitrogen-containing organic substance with a carbon-to-nitrogen ratio of 1:2, preferably selected from cyanamide, dicyandiamide, melamine, urea, guanidine hydrochloride, more preferably urea;

[0038] The boron source is selected from boron oxide, boric acid, sodium borate, potassium borate, sodium tetraphenylborate, and potassium tetraphenylborate, preferab...

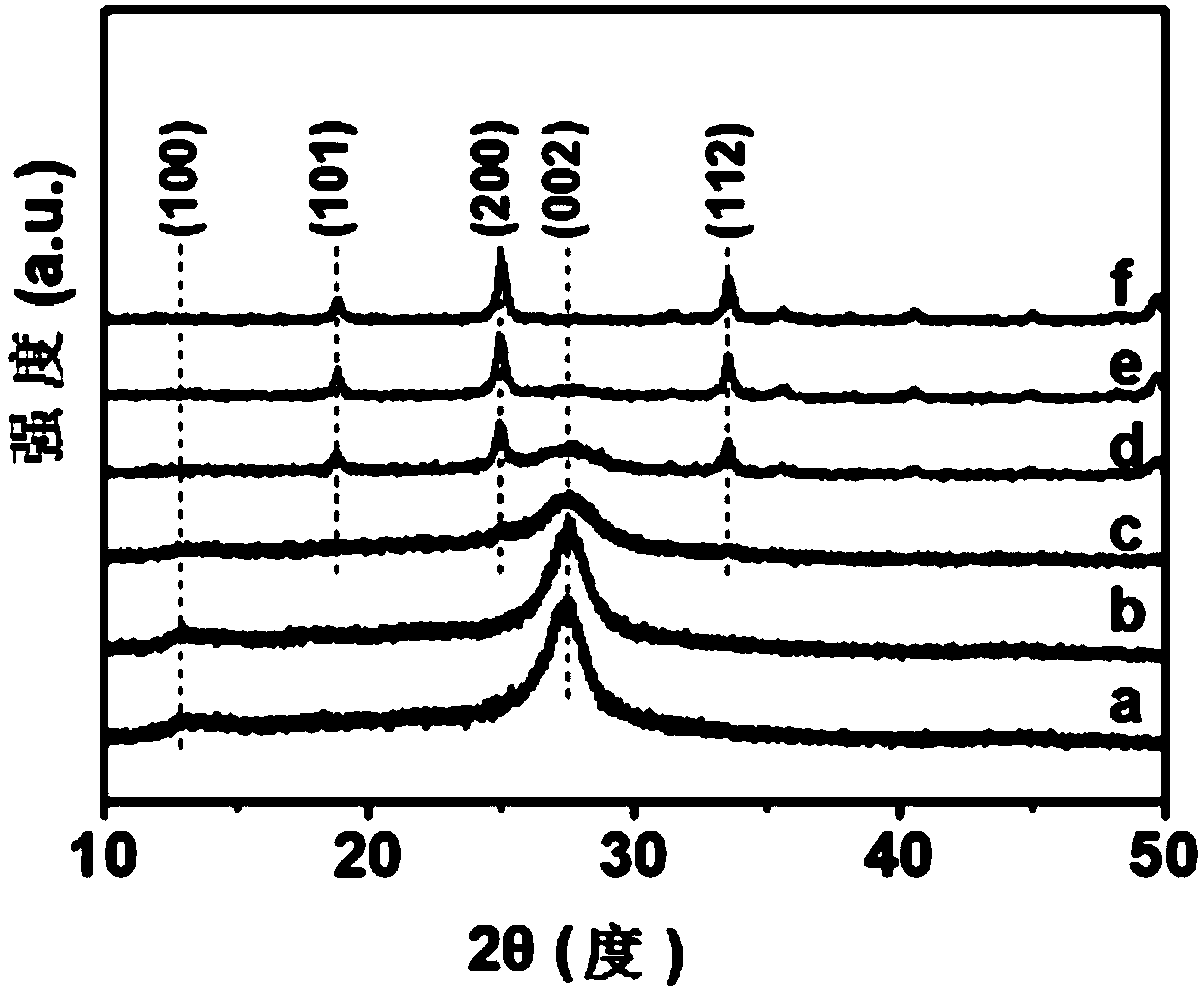

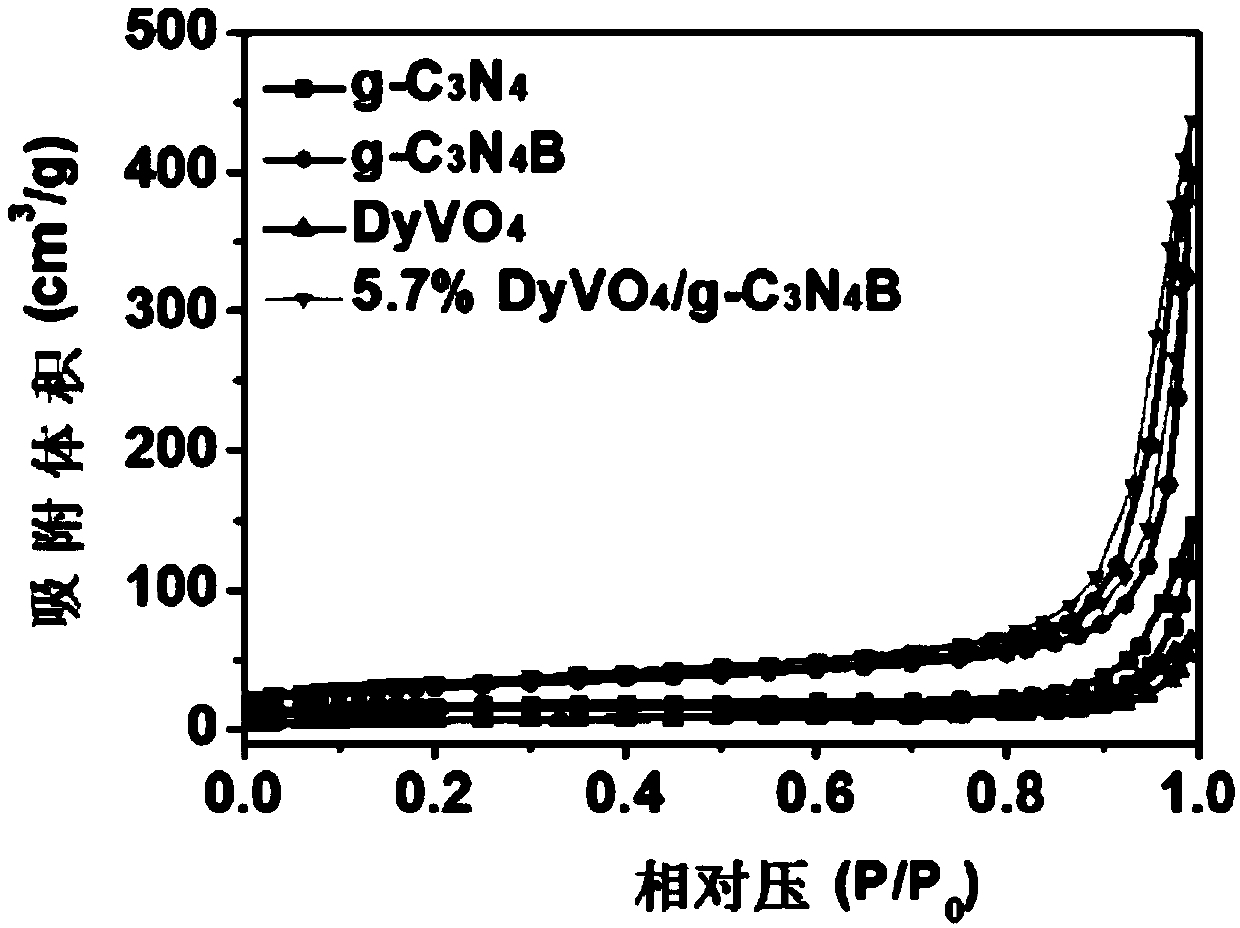

Embodiment 1

[0093] Take boron-doped graphitic carbon nitride (g-C 3 N 4 B) Sample 1g, and DyVO 4 Mixed grinding (wherein, DyVO 4 The quality of the DyVO 4 and g-C 3 N 4 The ratio of the sum of B masses is 2.9:100);

[0094] After calcination at 550°C for 4 hours in a muffle furnace, and grinding at room temperature, a composite photocatalyst was obtained, which was recorded as 2.9% DyVO 4 / g -C 3 N 4 b.

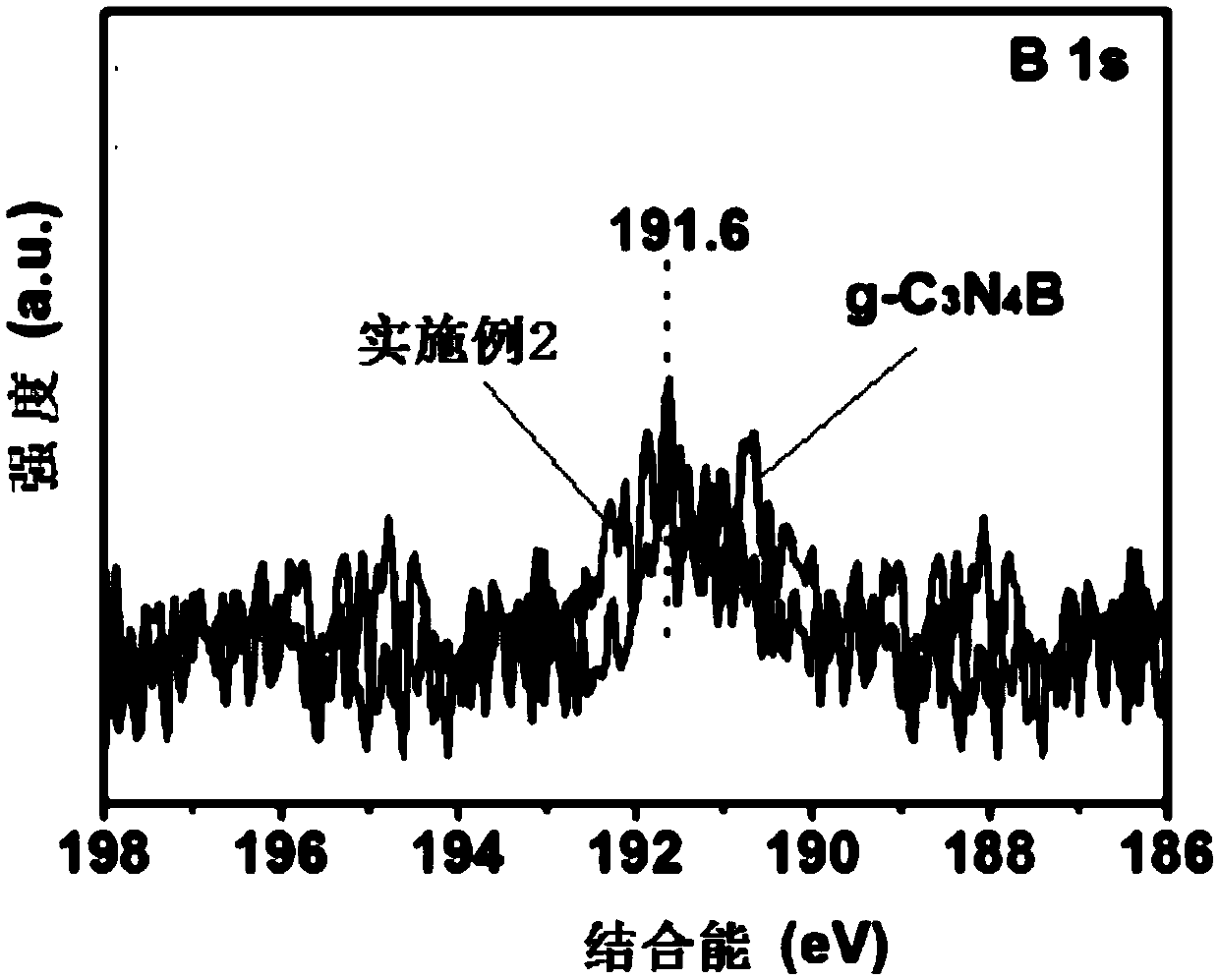

Embodiment 2

[0096] The present embodiment is the same as the method used in embodiment 1, the difference is only the DyVO used 4 different quality, in this example, DyVO 4 The quality of the DyVO 4 and g-C 3 N 4 The ratio of the sum of B masses is 5.7:100; the resulting product is recorded as 5.7% DyVO 4 / g -C 3 N 4 b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com