Three-dimensional cylindrical carving machine for portal column

An engraving machine, three-dimensional technology, applied in the direction of engraving, grinding frame, decorative arts, etc., can solve the problems of difficult to achieve large-scale rapid production, difficult to meet production delivery requirements, and high production time costs, to ensure production delivery needs, Simple structure and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

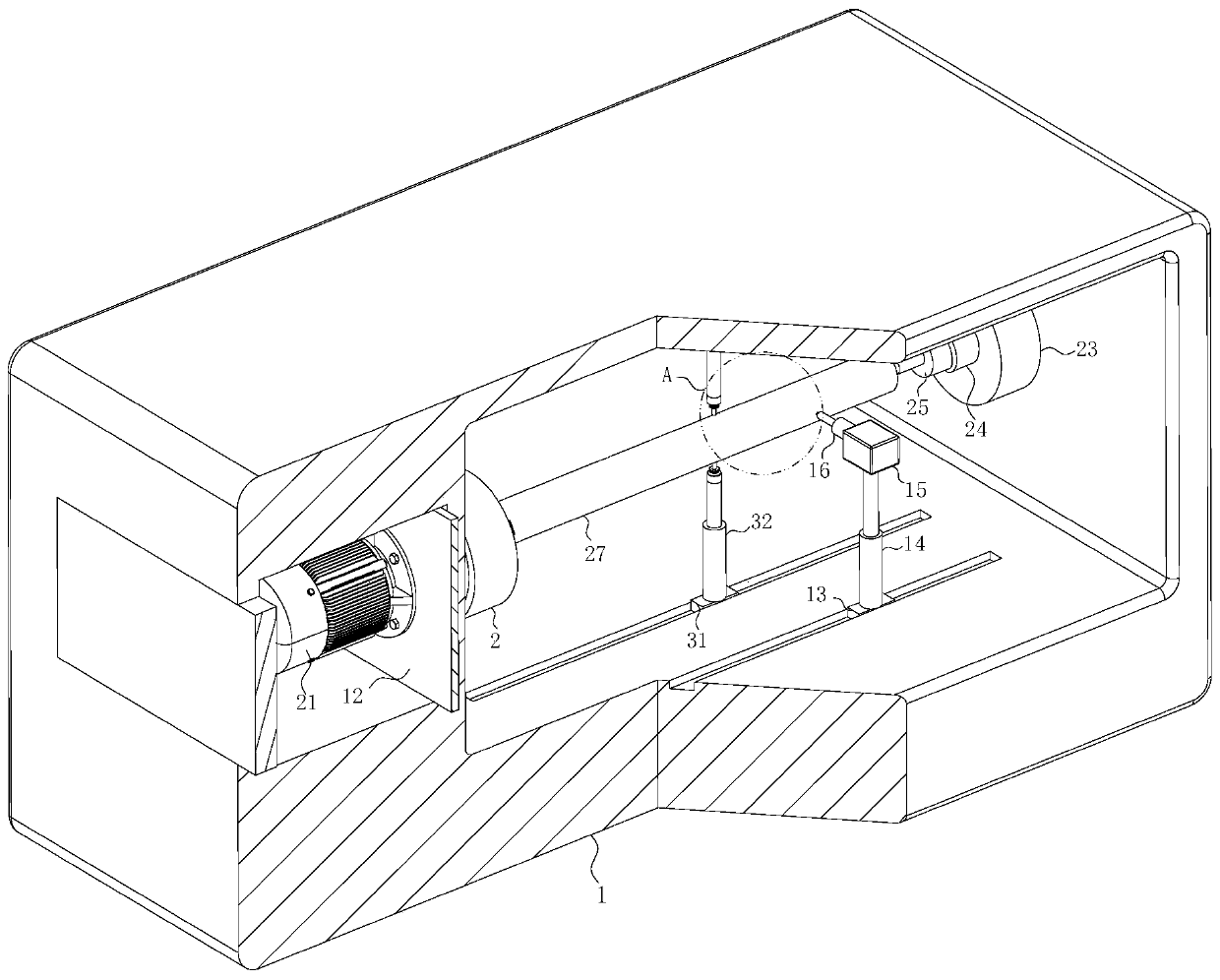

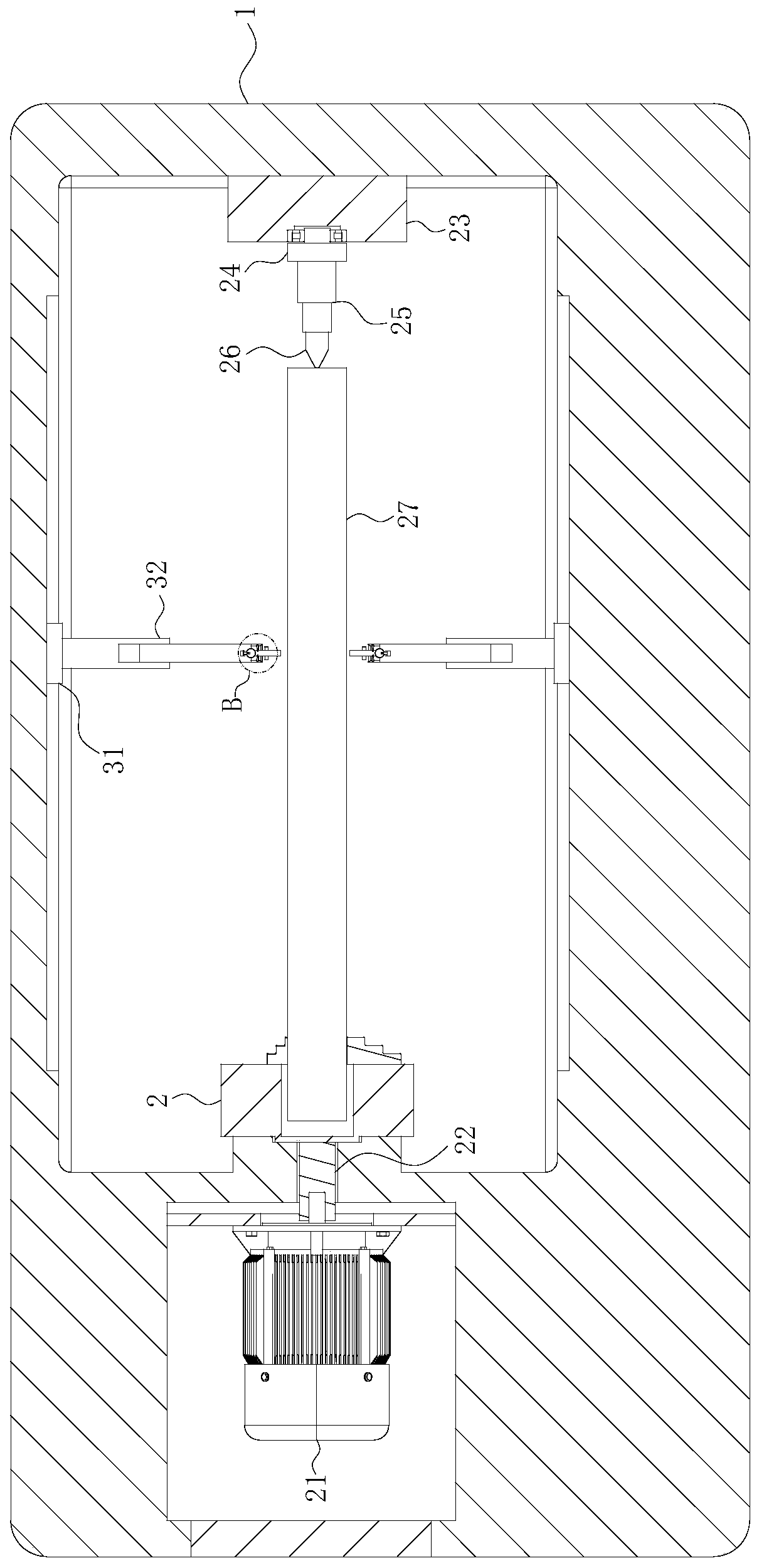

[0027] As an embodiment of the present invention, the outer arc surface of the carving knife 3 is connected with a side milling cutter 36 sliding up and down at the outer position corresponding to the fixed ring 33; the side milling cutter 36 is designed in a disc-shaped structure, and The outer arc surface of the side milling cutter 36 is provided with evenly arranged milling teeth; during work, since the maximum contour outer diameter of the finished gantry column has a large difference in different positions when the material column 27 is carved, only the carving knife 3 is used to remove the material. There is a large amount of material on the surface of the column 27, and the efficiency is low, and the workload of the carving knife 3 is greatly increased, and the service life of the carving knife 3 is reduced. Therefore, by socketing the side milling cutter 36 on the surface of the carving knife 3, the Knife 36 moves up and down on the surface of engraving knife 3, can rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com