Novel hydrogen peroxide purification method

A technology of hydrogen peroxide and a new method, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve the problem of high production and processing costs, high efficiency and Use low efficiency and other issues to achieve the effect of reducing production costs and improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

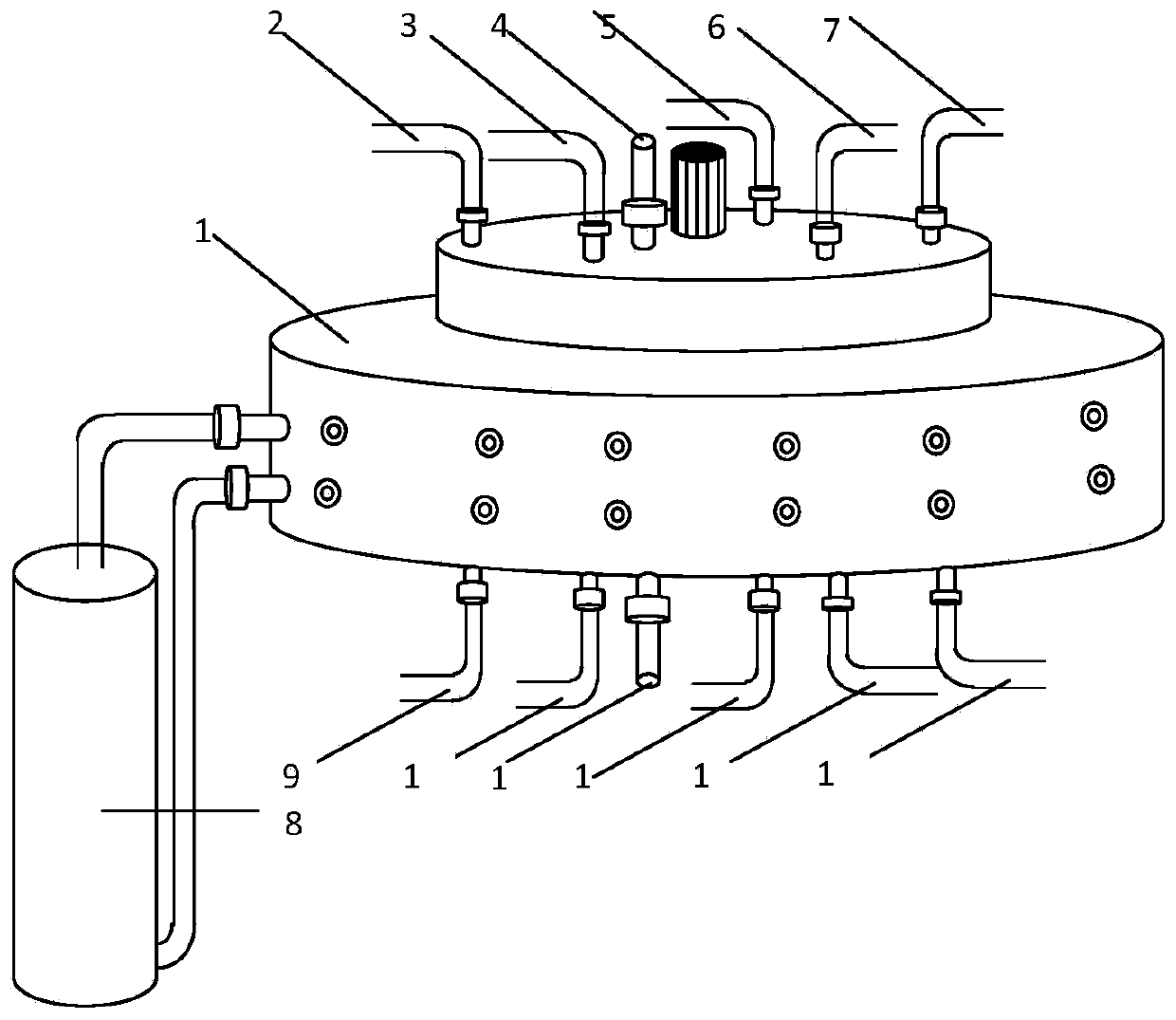

Embodiment 1

[0040] The hydrogen peroxide raw material, the replacement liquid A-water, the desorption liquid-90% (w / w) methanol solution, the replacement liquid B-water, and the finished hydrogen peroxide are respectively passed through the multi-way switching valve system 1 (the valve port diameter is 1.5 inches, and the rotation switching time is 3h) The hydrogen peroxide raw material tank feed pipe 9, the replacement liquid A feed pipe 3, the desorption liquid top replacement liquid A feed pipe 4, the desorption liquid feed pipe 5, the substitution liquid B feed pipe 6, the finished hydrogen peroxide replacement The feed pipe 14 enters into the corresponding resin column 8 through the inner hole and channel of the multi-way switching valve system respectively (filled with LX-5BX macroporous adsorption resin, produced by Xi'an Lanxiao Technology New Material Co., Ltd.), from the hydrogen peroxide finished product. Discharge pipe 2, displacement liquid A discharge pipe 10, desorption liqu...

Embodiment 2

[0050] The hydrogen peroxide raw material, the replacement fluid A-60% (w / w) ethanol solution, the desorption solution-50% (w / w) methanol solution, the replacement fluid B-water, and the finished hydrogen peroxide, respectively pass through the The diameter of the mouth is 1 inch, and the rotation switching time is 0.01h.) The hydrogen peroxide raw material tank feed pipe 9, the substitution liquid A feed pipe 3, the desorption liquid top substitution liquid A feed pipe 4, the desorption liquid feed pipe 5, the substitution liquid B feed pipe 6, the finished product hydrogen peroxide replaces the feed pipe 14, and enters the corresponding resin column 8 through the inner hole and channel of the multi-port valve system respectively (filled with LX-5BG macroporous adsorption resin, Xi'an Lanxiao Technology New Materials Co., Ltd. Co., Ltd.), from the hydrogen peroxide product discharge pipe 2, the replacement liquid A discharge pipe 10, the desorption liquid top replacement liqui...

Embodiment 3

[0060] The hydrogen peroxide raw material, the replacement solution A-5% (w / w) methanol solution, the desorption solution-5% (w / w) ethanol solution, the replacement solution B-hydrochloric acid, and the finished hydrogen peroxide, respectively pass through the multi-way switching valve system 1 (valve The diameter of the mouth is 1.5 inches, and the rotation switching time is 1h.) The hydrogen peroxide raw material tank feed pipe 9, the substitution liquid A feed pipe 3, the desorption liquid top substitution liquid A feed pipe 4, the desorption liquid feed pipe 5, the substitution liquid B Feed pipe 6, finished product hydrogen peroxide replace feed pipe 14, after entering into corresponding resin column 8 respectively through multi-port switching valve system inner pore channel and passage (filling macroporous adsorption resin LX-5BX, LX-5BG, resin volume ratio 1:1, produced by Xi'an Lanxiao Technology New Materials Co., Ltd.), from the hydrogen peroxide finished product disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com