Polymerizable eutectic solvent for self-repairing material, conductive elastomer and preparation method of conductive elastomer

A technology of deep eutectic solvent and self-healing materials, which is applied in the field of polymerizable eutectic solvents for self-healing materials, conductive elastomers and their preparation, and can solve the problem of reduced transparency of self-healing materials, limiting the use of self-healing materials, and inability to maintain Self-moisture and other problems, to achieve the effect of excellent self-healing ability, low cost, good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

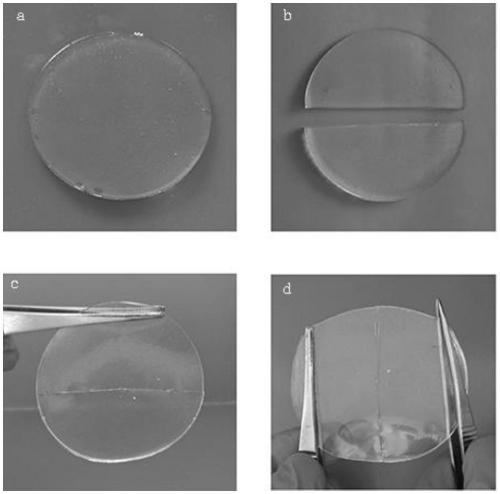

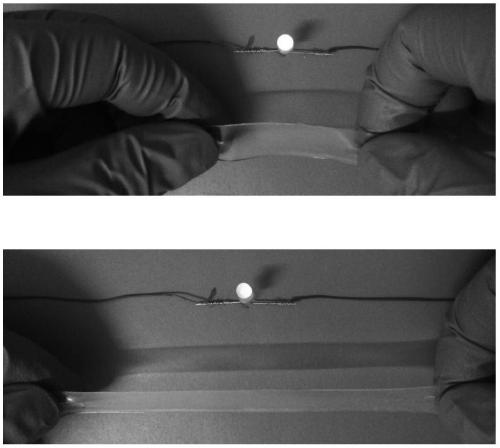

Image

Examples

Embodiment 1

[0038] A polymerizable eutectic solvent for self-healing materials, the preparation process is as follows: 13.96g hydrogen bond acceptor choline chloride, 5.8035g hydrogen bond donor maleic acid and 3.554g hydrogen bond donor acrylamide in 60 The reaction was stirred at ℃ for 4h to obtain a clear and transparent polymerizable eutectic solvent.

[0039] The glass transition temperature of the polymerizable eutectic solvent measured by differential scanning calorimetry was -104.2°C.

Embodiment 2

[0041] A polymerizable eutectic solvent for self-healing materials, the preparation process is as follows: 13.96g hydrogen bond acceptor choline chloride, 3.6g hydrogen bond donor acrylic acid and 3.554g hydrogen bond donor acrylamide at 60℃ Stir the reaction for 4h to obtain a clear and transparent polymerizable eutectic solvent.

Embodiment 3

[0043] A polymerizable eutectic solvent for self-healing materials, the preparation process is as follows: 13.96g hydrogen bond acceptor choline chloride, 4.3g hydrogen bond donor methacrylic acid and 3.554g hydrogen bond donor acrylamide in 60 The reaction was stirred at ℃ for 4h to obtain a clear and transparent polymerizable eutectic solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com