Oxidizing agent for harmless treatment of drilling waste solid water-based mud, and preparation method and application thereof

An oxidant and mud technology, which is applied in mining wastewater treatment, oxidation treatment of sludge, etc., to achieve the effects of simple operation, improved oxidation activity, and strong oxidation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1. Preparation of oxidizing agent

[0028] Oxidant formulation of the present invention: in parts by weight, 30-50 parts of active agent, 5-15 parts of dicalcium hydrogen phosphate, 5-15 parts of sodium pyrophosphite, 5-15 parts of methylene dithiocyanate, 20-40 parts water.

[0029] For evaluating the performance of oxidizing agent of the present invention, prepare respectively following No. 1-3 oxidizing agent:

[0030] No. 1 oxidizing agent: in parts by weight, 30 parts of active agent, 15 parts of dicalcium hydrogen phosphate, 5 parts of sodium pyrophosphite, 15 parts of methylene dithiocyanate, and 20 parts of water.

[0031] No. 2 oxidizing agent: in parts by weight, 50 parts of active agent, 10 parts of dicalcium hydrogen phosphate, 10 parts of sodium pyrophosphite, 5 parts of methylene dithiocyanate, and 25 parts of water.

[0032] No. 3 oxidizing agent: in parts by weight, 40 parts of active agent, 5 parts of dicalcium hydrogen phosphate, 15 parts ...

Embodiment 2

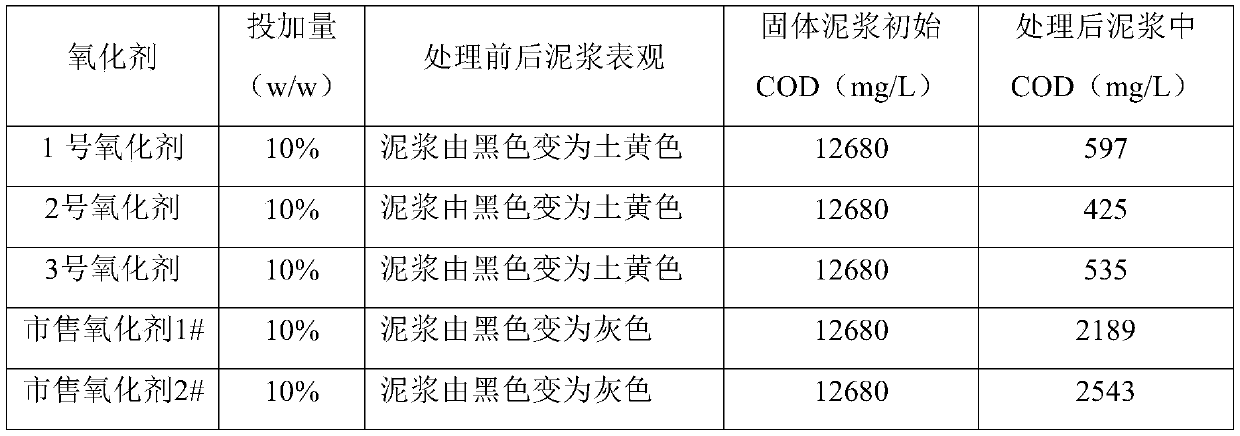

[0041] Embodiment 2. Water Solubility Evaluation of Oxidizing Agent

[0042] Detect the water-solubility of oxidant of the present invention according to following method: get 3 glass beakers, each beaker adorns 100ml water, add No. , Shake well and let it stand at room temperature for 5 minutes to observe the dissolution of the oxidant. The results are shown in Table 1, and No. 1-3 oxidants have good water solubility.

[0043] The water solubility evaluation table of table 1 oxidant

[0044] oxidizing agent Solution Appearance Dissolution rate (%) Oxidant No. 1 Soluble 100 Oxidant No. 2 Soluble 100 Oxidant No. 3 Soluble 100

Embodiment 3

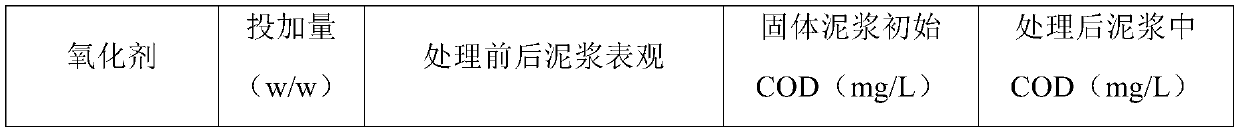

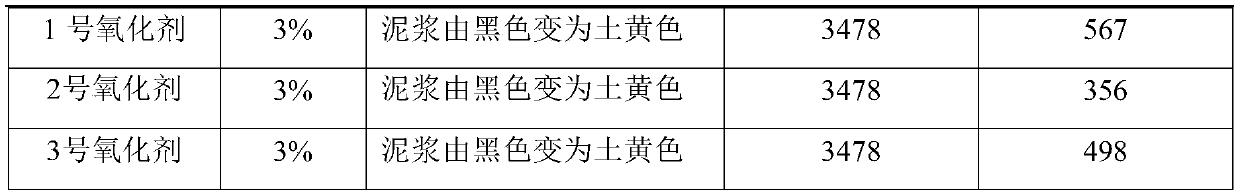

[0045] Embodiment 3. Effect evaluation of oxidizing agent

[0046] Use No. 1-3 oxidants prepared in Example 1 to treat drilling waste solid water-based mud, and evaluate the oxidation effect. The low-concentration solid water-based mud waste used in this experiment was taken from an oilfield in Wuqia County, Xinjiang, and the high-concentration sulfonated water-based mud waste used was taken from the Tarim Oilfield in Xinjiang.

[0047] The mud treatment method is: take a certain amount of waste solid water-based mud, put it into a beaker after weighing, add 3% to 10% of the total weight of the mud solid oxidizer, stir evenly, so that the oxidant and mud are fully mixed, and keep the mud in the mud. The water content of the beaker is above 30% (the method of maintaining the water content is sealing: after mixing the oxidant and water-based mud evenly, wrap or cover the mouth of the beaker with plastic wrap or a sealed bag with the same size as the mouth of the beaker, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Cod value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com