Admixture for ultra-high performance concrete and preparation method thereof

An ultra-high-performance concrete technology, applied in the field of concrete additives, can solve the problems of difficult air bubble discharge, large shrinkage, poor early strength, etc., and achieve the effects of reducing heat of hydration, inhibiting shrinkage, and inhibiting hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

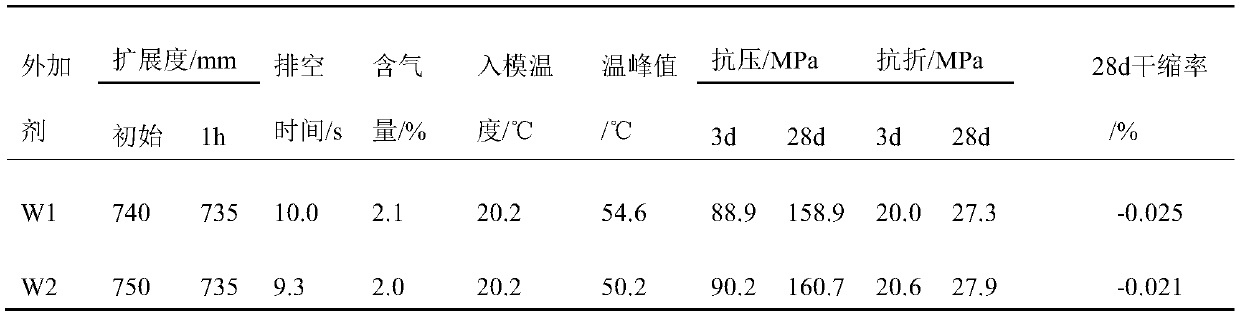

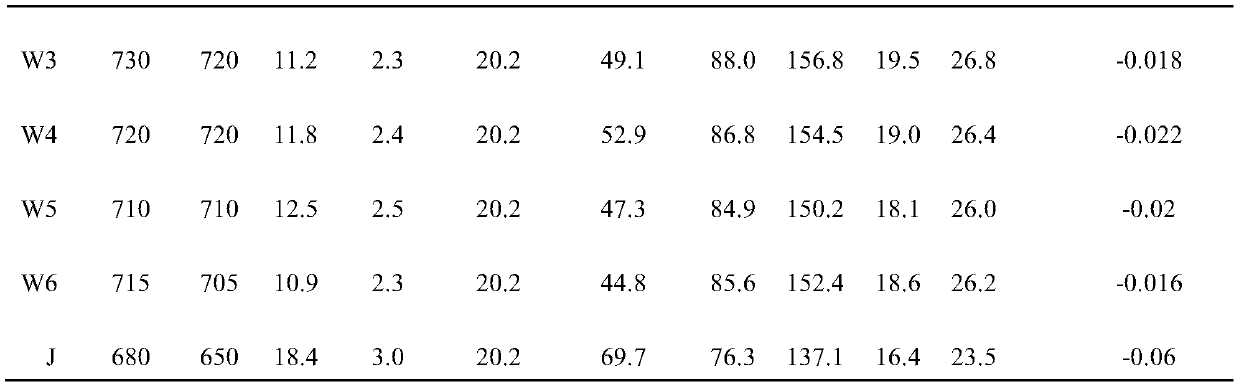

Examples

Embodiment 1

[0046] (1) Synthesis of viscosity reducing agent:

[0047] First, add methoxypolyethylene glycol acrylate with a molecular weight of 350 and deionized water into the reaction kettle and stir to raise the temperature to 40°C to obtain A solution;

[0048] Then add hydrogen peroxide in the A solution, and drop the deionized water mixed solution of ascorbic acid and thioglycolic acid and the deionized water mixed solution of acrylic acid, diethylene glycol monoacrylate and vinyl acetate respectively simultaneously, and the dropping time is 2h, After the dropwise addition, keep the reaction at 40°C for 1.5h, then cool to room temperature to obtain solution B;

[0049] Finally, liquid caustic soda is added to solution B, and the pH value is adjusted to 6-7 to obtain a viscosity-reducing agent; among them, methoxypolyethylene glycol acrylate, acrylic acid, diethylene glycol monoacrylate, vinyl acetate, hydrogen peroxide , Ascorbic acid, thioglycolic acid mass ratio is 3.5:1:0.55:0....

Embodiment 2

[0053] (1) Synthesis of viscosity reducer and shrinkage reducer: with embodiment 1.

[0054] (2) Preparation of admixture: at normal temperature, first add 70% polycarboxylate superplasticizer in the production equipment according to the mass ratio, then add 3% hydration heat inhibitor under the condition that the rotating speed is 240rpm, stir 15 to 20 minutes; then add 12% viscosity reducer and stir for 10 to 15 minutes; finally add 15% polycarboxylate slump retaining agent and stir until transparent and free of air bubbles to obtain the admixture for large-volume ultra-high performance concrete W-2.

Embodiment 3

[0056] (1) Synthesis of viscosity reducer and shrinkage reducer: first add methoxypolyethylene glycol acrylate with a molecular weight of 400 and deionized water into the reactor and stir to raise the temperature to 50°C to obtain A solution;

[0057] Then add hydrogen peroxide to solution A, and drop the deionized water mixed solution of ascorbic acid and thioglycolic acid and the deionized water mixed solution of acrylic acid, diethylene glycol monoacrylate and vinyl acetate respectively dropwise at the same time, and the dropping time is 2.5h , after the dropwise addition, keep the reaction at 50°C for 1h, then cool to room temperature to obtain the B solution;

[0058] Finally, liquid caustic soda is added to solution B, and the pH value is adjusted to 6-7 to obtain a viscosity-reducing agent; wherein methoxypolyethylene glycol acrylate, acrylic acid, diethylene glycol monoacrylate, vinyl acetate, hydrogen peroxide , Ascorbic acid, thioglycolic acid mass ratio is 4.0:1:0.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com