Epoxy polyurethane gloss varnish

An epoxy polyurethane and clear topcoat technology, applied in the field of coatings, can solve the problems of poor weather resistance, restricted materials, and poor paint film fullness, and achieve the effect of improving gloss, maintaining excellent performance, and meeting the requirements of high gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

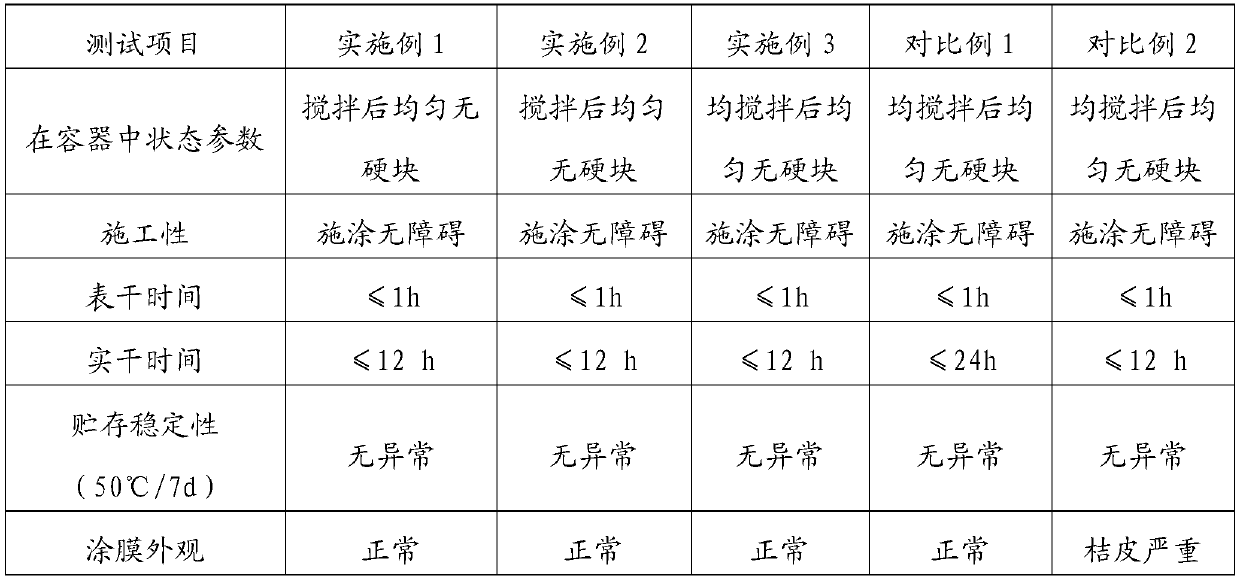

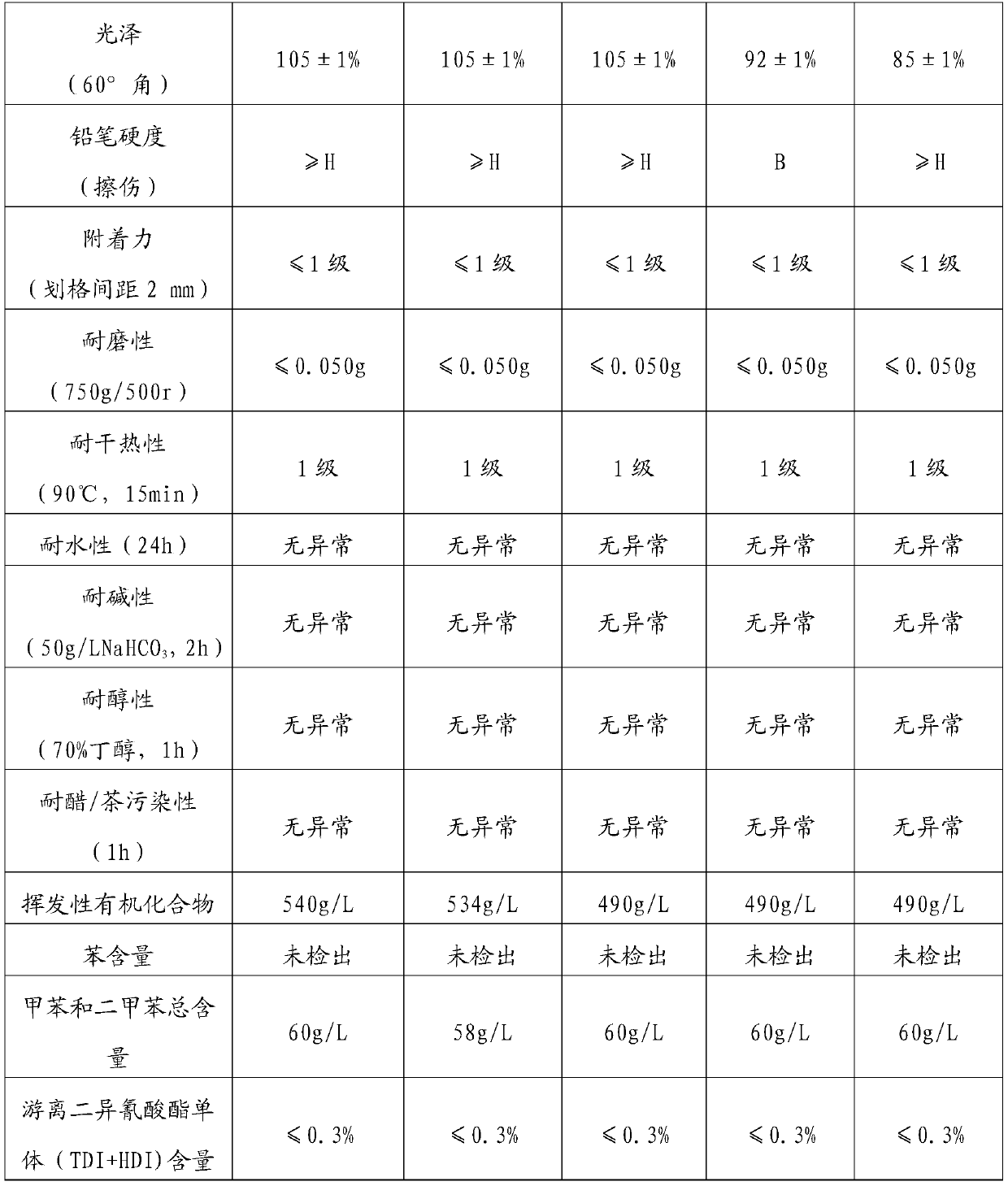

Examples

Embodiment 1

[0030] A kind of epoxy polyurethane gloss clear finish paint, comprises main agent, curing agent and diluent;

[0031] The main agent is made of the following components: 85kg of epoxy resin, 14.7kg of ethyl acetate, 0.2kg of defoamer and 0.1kg of leveling agent;

[0032] The curing agent is made of the following components: 50kg of toluene diisocyanate (TDI) adduct and 50kg of butyl acetate;

[0033] Described diluent is made of following components: the butyl acetate of 50kg and the propylene glycol methyl ether acetate of 50kg;

[0034] The epoxy resin is Miki SM601-75.

[0035] The preparation method of the above-mentioned epoxy polyurethane clear finish paint is as follows: add epoxy resin in a clean and pollution-free container, add ethyl acetate, defoamer, and leveling agent in turn under stirring conditions, and disperse evenly to obtain the main agent;

[0036] Stir and mix the main agent, curing agent and diluent according to the weight ratio of the main agent, cur...

Embodiment 2

[0038] A kind of epoxy polyurethane gloss clear finish paint, comprises main agent, curing agent and diluent;

[0039] The main agent is made of the following components: 88kg of epoxy resin, 11.7kg of ethyl acetate, 0.3kg of defoamer and 0.3kg of leveling agent;

[0040] The curing agent is made of the following components: 55kg of toluene diisocyanate (TDI) adduct and 45kg of butyl acetate;

[0041] Described diluent is made up of following components: the butyl acetate of 40kg and the propylene glycol methyl ether acetate of 60kg;

[0042] In the above-mentioned epoxy polyurethane clear finish paint, the weight ratio of main agent, curing agent and diluent is 1:0.55:0.35; the main agent curing agent and diluent are stirred and mixed according to the ratio to obtain the epoxy polyurethane clear finish paint;

[0043] The epoxy resin is a bisphenol A type epoxy resin with an epoxy value of 20.

Embodiment 3

[0045] A kind of epoxy polyurethane gloss clear finish paint, comprises main agent, curing agent and diluent;

[0046] The main agent is made of the following components: 90kg of epoxy resin, 9.3kg of ethyl acetate, 0.4kg of defoamer and 0.3kg of leveling agent;

[0047] The curing agent is made of the following components: 60kg of toluene diisocyanate (TDI) adduct and 40kg of butyl acetate;

[0048] Described diluent is made of following components: the butyl acetate of 60kg and the propylene glycol methyl ether acetate of 40kg;

[0049] In the above-mentioned epoxy polyurethane clear finish paint, the weight ratio of the main agent, curing agent and diluent is 1:0.6:0.25; the main agent curing agent and the diluent are stirred and mixed in proportion to obtain the epoxy polyurethane bright clear surface paint;

[0050] The epoxy resin is Miki SM601-75; the defoamer is BYK066N, and the leveling agent is Efka EFKA3600; the toluene diisocyanate (TDI) adduct curing agent is Baye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap