Optical fiber gas pressure sensor and preparation method thereof

A gas pressure and sensor technology, which is applied in the application of optical methods for fluid pressure measurement, fluid pressure measurement, instruments, etc., can solve the problems of weak structural strength, difficult film preparation methods for plugging, temperature crosstalk, etc., and achieves low cost, High mechanical strength and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

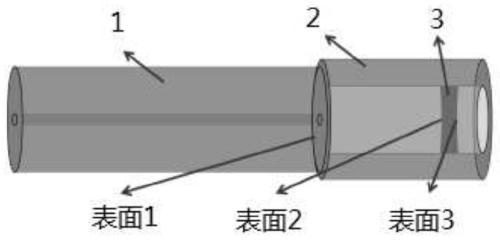

[0027] Specific implementation mode one: combine figure 1 Describe this embodiment, the fiber optic gas pressure sensor of this embodiment is an FPI fiber optic gas sensor;

[0028] The optical fiber gas pressure sensor is composed of a hollow-core optical fiber 2, a single-mode optical fiber 1 and a film 3, wherein one end 2 of the hollow-core optical fiber is welded to the single-mode optical fiber 1, and the other end of the hollow-core optical fiber is blocked with a film 3; Dimethylsiloxane film.

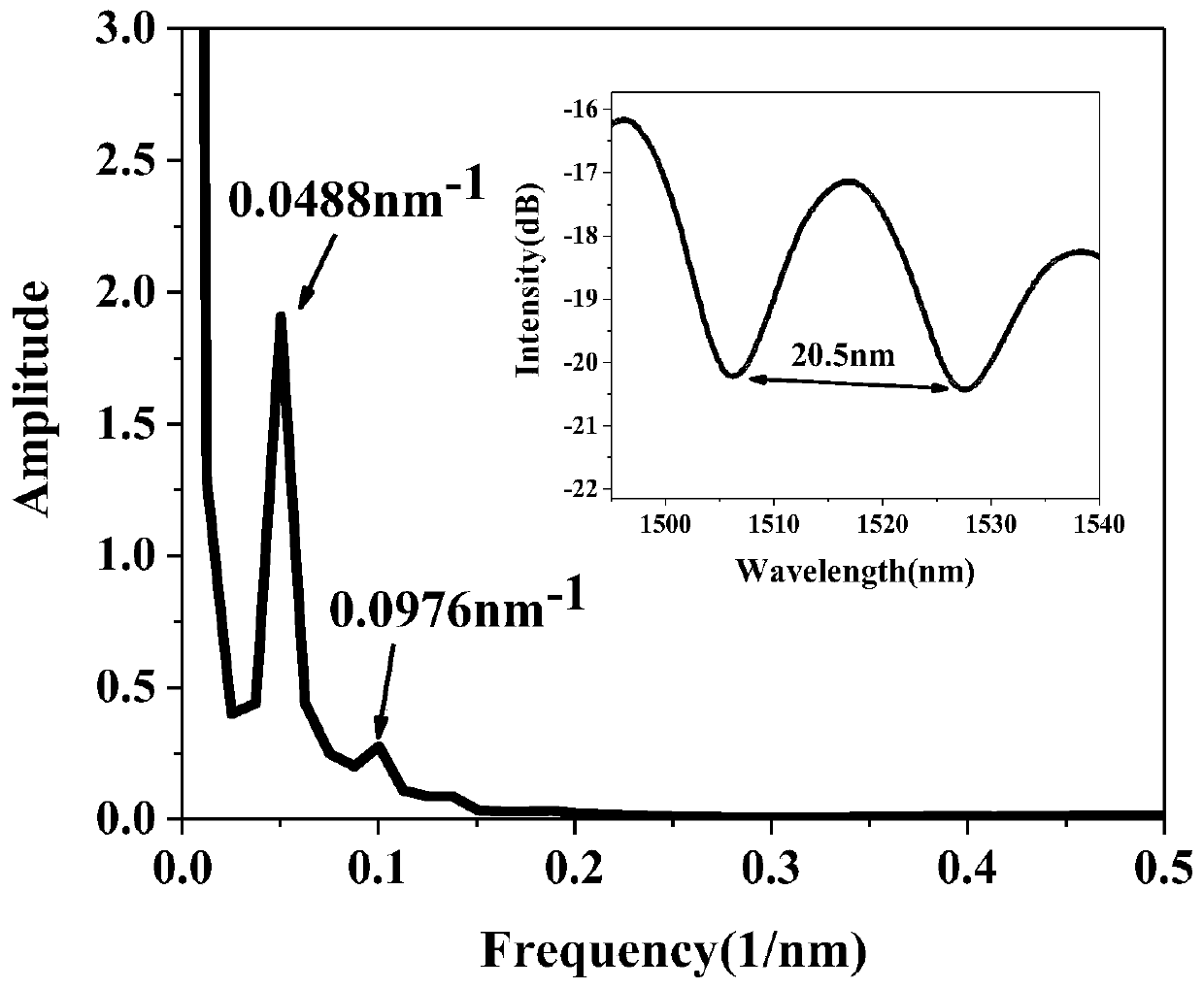

[0029] The optical fiber gas pressure sensor in this embodiment has three reflection surfaces, which are respectively named surface 1, surface 2 and surface 3. The three surface joint structures are divided into two FPI structures, one formed by surface 1 and surface 2, and the other formed by surface 1 and surface 3. However, the surface 3 in direct contact with the external environment is susceptible to fouling, resulting in roughening of the surface and reduction in reflec...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the thickness of the polydimethylsiloxane film is 1-71 μm. Other steps and parameters are the same as those in Embodiment 1.

[0031] The thickness of the polydimethylsiloxane film is the middle thickness of the film.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the thickness of the polydimethylsiloxane film is 3 μm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com