High-temperature insulated wire, preparation method and coating equipment

A technology of coating equipment and workbench, which is applied in the direction of inorganic insulator, cable/conductor manufacturing, conductor/cable insulation, etc. It can solve the problems of unfavorable use and poor effect of high temperature resistance, so as to speed up the practicality and work efficiency , the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of the application:

[0045] Step 1: weighing; weighing according to the components: 50-70 parts of Na 2 SiO 3 , 20-30 parts of (NaPO 3 )6, 15-25 parts of NaOH;

[0046] Step 2: Mix the components weighed in step 1, add deionized water, and stir and mix with a stirrer at room temperature to form an electrolyte;

[0047] Step 3: Put the electrolyte solution obtained in step 2 into the thermoelectrochemical oxidation electrolytic cell, stir it with a stirrer, and control the temperature of the electrolyte solution through a condensation tower;

[0048] Step 4: cleaning the conductor made of 1050 aluminum alloy with an ultrasonic cleaner, and coating the surface with K 3 PO 4 solution to obtain a wire core;

[0049] Step 5: Connect the wire core obtained in step 4 to the positive electrode of the bipolar pulse voltage source, and place it in the electrolyte obtained in step 3;

[0050] Step 6: Turn on the switch of the bipolar pulse voltage source ...

Embodiment 2

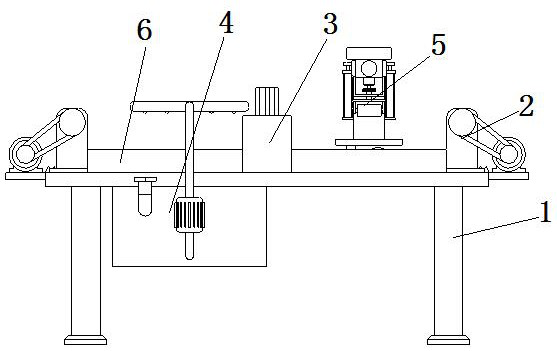

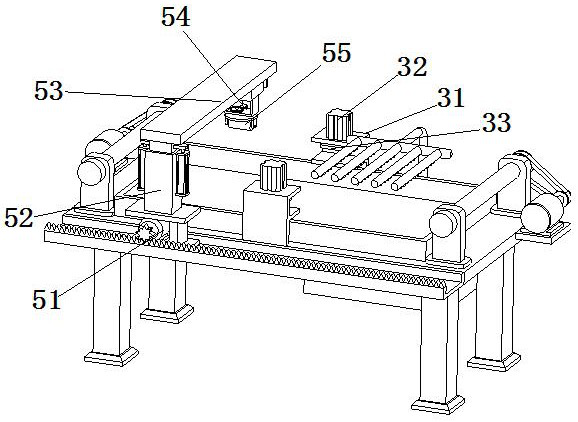

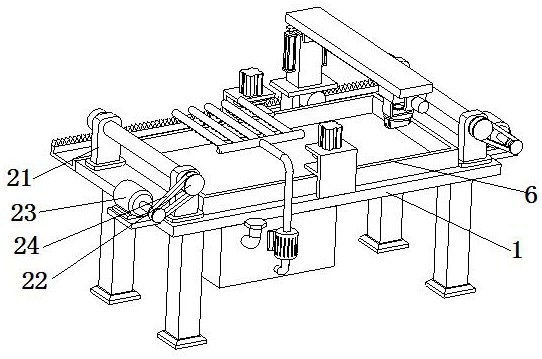

[0055] combine Figure 1 to Figure 7 As shown, the present invention provides a kind of coating equipment, comprises workbench 1, winding assembly 2, clamping assembly 3, spraying assembly 4, scraping assembly 5 and recovery box 6, and described winding assembly 2 is provided with two groups Two groups of winding assemblies 2 are symmetrically arranged on both sides of the workbench 1, two sets of clamping assemblies 3 are provided, and two groups of clamping assemblies 3 are arranged in pairs on the other two sides of the workbench 1, The spraying assembly 4 is fixedly arranged on one side below the workbench 1, the working end of the spraying assembly 4 extends above the workbench 1, the scraper assembly 5 is fixedly arranged on the side of the workbench 1, and the scraper The uniform assembly 5 includes a moving part 51, a lifting part 52, an adjusting part 53, a steering part 54 and a scraping cylinder 55, the moving part 51 is fixedly arranged on the side of the workbench...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com