Fluorine-removing composite fiber membrane as well as preparation method and application thereof

A composite fiber membrane, polyvinylidene fluoride technology, applied in fiber treatment, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of limiting the adsorption efficiency and performance of chitosan, and achieve adsorption equilibrium in a short time and a form of use. Convenience and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

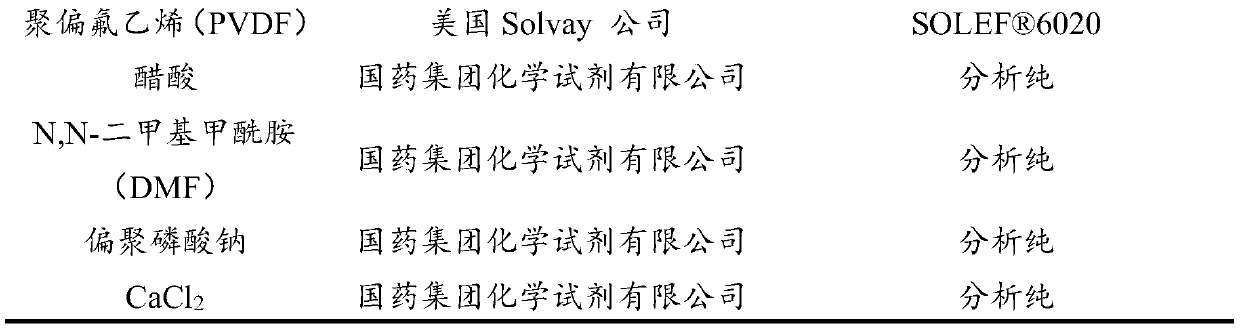

[0047] 1) Take 1 g of PVDF and 10 g of chitosan, add them into a mixed solvent composed of 10 g of acetic acid and 20 g of DMF, stir at room temperature for 5 hours, and obtain an electrospinning precursor solution.

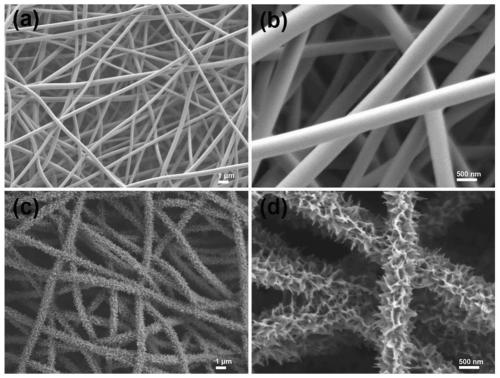

[0048] 2) Take the precursor solution prepared above and carry out electrospinning on the electrospinning equipment. During the electrospinning process, the ambient temperature is 25°C, the relative humidity is 85%, the electrospinning voltage is 15kV, the collection distance is 15cm, and the electrospinning time is After 5 hours, the electrospun fiber membrane was collected and dried in a vacuum oven at 120°C for 24 hours to obtain a PVDF / chitosan composite fiber membrane. The SEM image is as follows: figure 1 (a) and (b) Figures.

[0049] 3) Take 1g of calcium chloride and 5g of sodium metapolyphosphate, add them to 20g of acetic acid solution (the mass fraction of acetic acid is 5%), and after stirring vigorously for 1h, prepare 11g of PVDF / chitosan composite ...

Embodiment 2

[0051] 1) Take 5 g of PVDF and 10 g of chitosan, add them into a mixed solvent composed of 20 g of acetic acid and 20 g of DMF, and stir for 1 h at room temperature to obtain an electrospinning precursor solution.

[0052] 2) Take the precursor solution prepared above and carry out electrospinning on the electrospinning equipment. During the electrospinning process, the ambient temperature is 100°C, the relative humidity is 60%, the electrospinning voltage is 30kV, the collection distance is 30cm, and the electrospinning time is After 2 hours, the electrospun fiber membrane was collected and dried in a vacuum oven at 120° C. for 24 hours to obtain a PVDF / chitosan composite fiber membrane.

[0053] 3) Take 1g of calcium chloride and 5g of sodium metapolyphosphate, add it to 20g of acetic acid solution (the mass fraction of acetic acid is 5%), and after stirring vigorously for 1h, prepare 15g of PVDF / chitosan composite fiber membrane at room temperature Add it to the above prepa...

Embodiment 3

[0055] 1) Take 5g of PVDF and 15g of chitosan, add them into a mixed solvent composed of 20g of acetic acid and 40g of DMF, and stir for 2 hours at room temperature to obtain an electrospinning precursor solution.

[0056] 2) Take the precursor solution prepared above and carry out electrospinning on the electrospinning equipment. During the electrospinning process, the ambient temperature is 80°C, the relative humidity is 75%, the electrospinning voltage is 15kV, the collection distance is 25cm, and the electrospinning time is After 15 hours, the electrospun fiber membrane was collected and dried in a vacuum oven at 120° C. for 24 hours to obtain a PVDF / chitosan composite fiber membrane.

[0057] 3) Take 5g of calcium chloride and 10g of sodium metapolyphosphate, add them to 40g of acetic acid solution (the mass fraction of acetic acid is 20%), and after stirring vigorously for 2 hours, prepare 20g of PVDF / chitosan composite fiber membrane at room temperature Add it to the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com