Comprehensive utilization method of organic hazardous waste salt slag

A waste salt residue, organic technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of easily polluting the landfill environment, high landfill costs, and achieve the effect of controllable pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

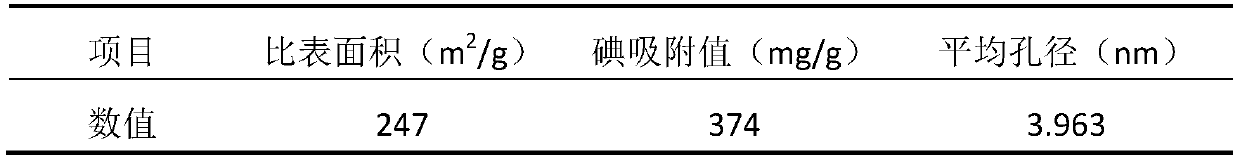

[0024] Take an appropriate amount of organic hazardous waste salt slag and dry it at 100°C for 180 minutes. The dried organic hazardous waste salt slag is pre-carbonized in a tube furnace at 400°C for 150 minutes. The treated residue was ground and passed through a 100-mesh sieve, and then redissolved at a solid-to-liquid ratio of 0.01. The filtrate was collected by filtration, and the filtrate was dried at 100°C for 180 minutes to obtain net salt. Add activator (KOH solution) with a mass concentration of 20% to the filter residue with a ratio of activator to carbonization product mass ratio of 2, let it stand at room temperature for 4h, filter, and dry the filter cake, then put it in a muffle furnace at 400 ° C Calcination and activation for 30 minutes to obtain activated carbon. See Table 1-1, 1-2, 1-3 for related indicators.

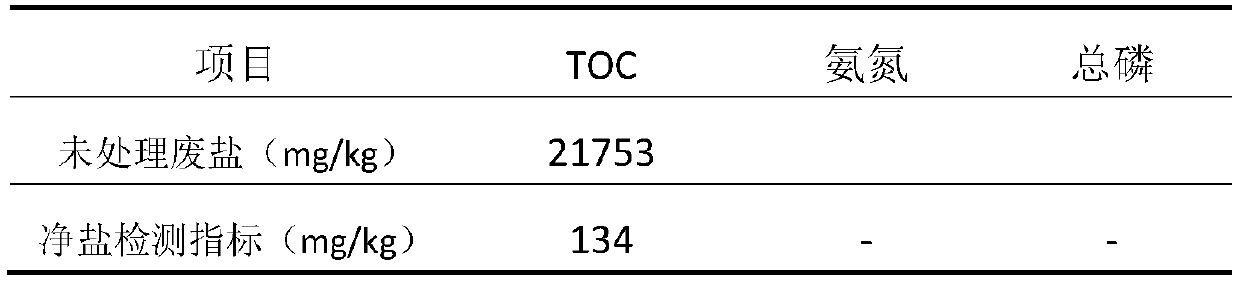

[0025] The net salt detection index in the table 1-1 embodiment 1

[0026]

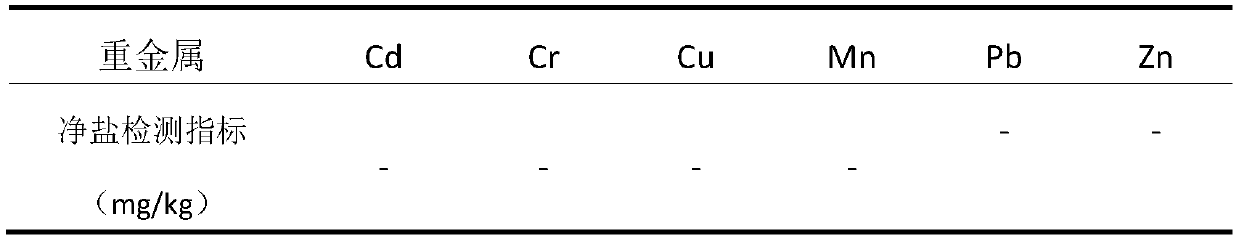

[0027] The heavy metal leaching value in the table 1-2 embodiment 1...

Embodiment 2

[0032] Take an appropriate amount of organic hazardous waste salt slag and dry it at 105°C for 150 minutes, and the dried organic hazardous waste salt slag is pre-carbonized in a tube furnace at 450°C for 120 minutes. The treated residue was ground and passed through a 100-mesh sieve, and then redissolved at a solid-to-liquid ratio of 0.03. The filtrate was collected by filtration, and the filtrate was dried at 105°C for 150 minutes to obtain net salt. Add activator (KOH solution) with a mass concentration of 30% to the filter residue with a ratio of activator to carbonization product mass ratio of 3, let it stand at room temperature for 6 hours, filter, and dry the filter cake, then put it in a muffle furnace at 450 ° C Calcination and activation for 60 minutes to obtain activated carbon. See Table 2-1, 2-2, 2-3 for related indicators.

[0033] The net salt detection index in the table 2-1 embodiment 2

[0034]

[0035]

[0036] The heavy metal leaching value in the t...

Embodiment 3

[0041] Take an appropriate amount of organic hazardous waste salt slag and dry it at 110°C for 120 minutes, and the dried organic hazardous waste salt slag is pre-carbonized in a tube furnace at 500°C for 90 minutes. The treated residue was ground and passed through a 100-mesh sieve, and then redissolved at a solid-to-liquid ratio of 0.05. The filtrate was collected by filtration, and the filtrate was dried at 110°C for 120 minutes to obtain net salt. Then add the activator (KOH solution) that mass concentration is 40% to filter residue with the ratio of activator to carbonization product mass ratio is 4, leave standstill 8h at normal temperature, filter, filter cake is dried, behind the 500 in the muffle furnace ℃ calcination and activation for 90 minutes to obtain activated carbon. See Table 3-1, 3-2, 3-3 for related indicators.

[0042] The net salt detection index in the table 3-1 embodiment 3

[0043]

[0044] The heavy metal leaching value in the table 3-2 embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com