Polybutylene terephthalate composition and preparation method thereof

A technology of polybutylene terephthalate and composition, applied in the field of polybutylene terephthalate composition and its preparation, can solve the problem of low impact strength, low molecular chain flexibility, high molecular rigidity, etc. problems, to achieve the effect of high melting point, excellent processing performance, and little impact on mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

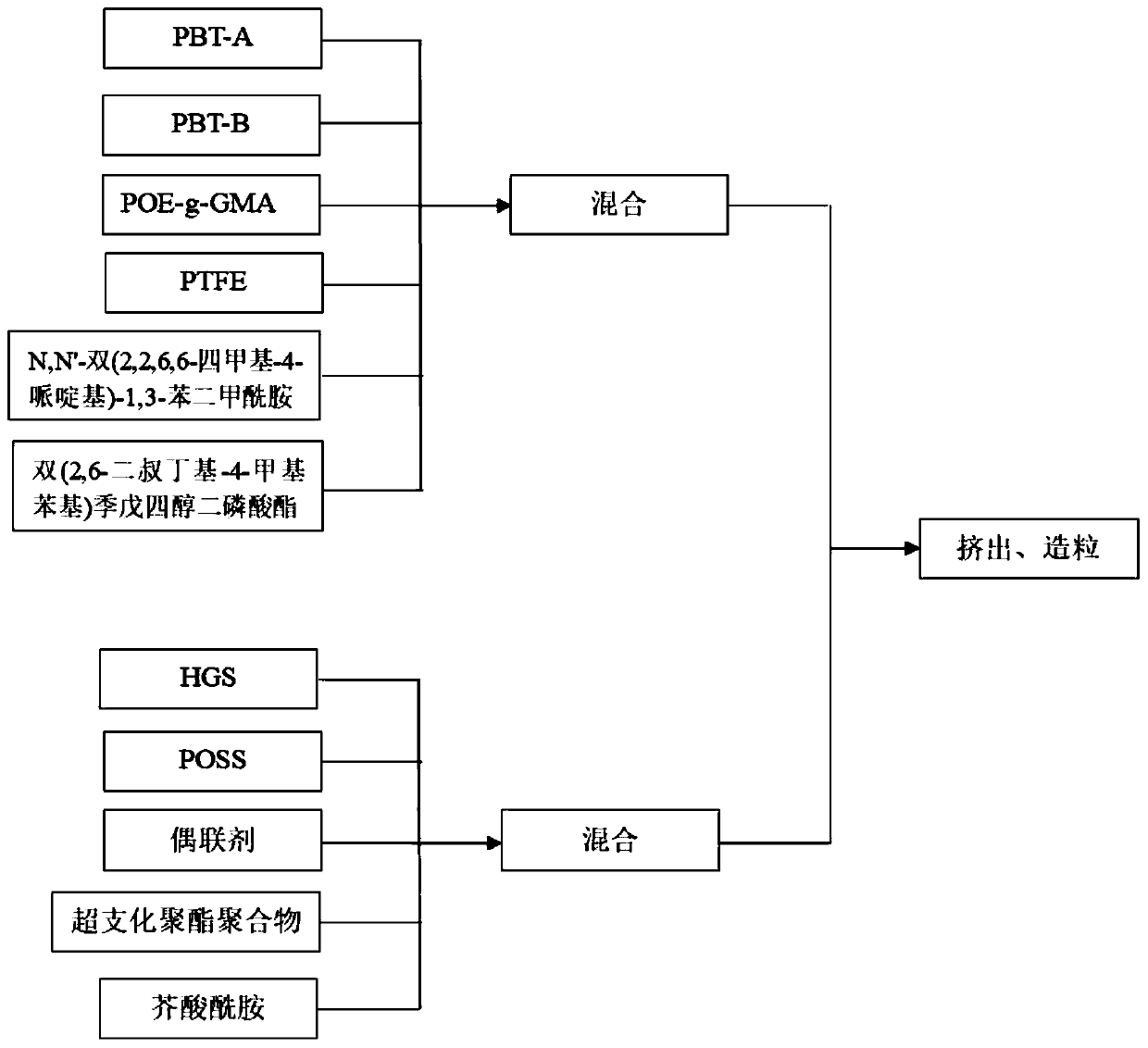

Method used

Image

Examples

Embodiment 1

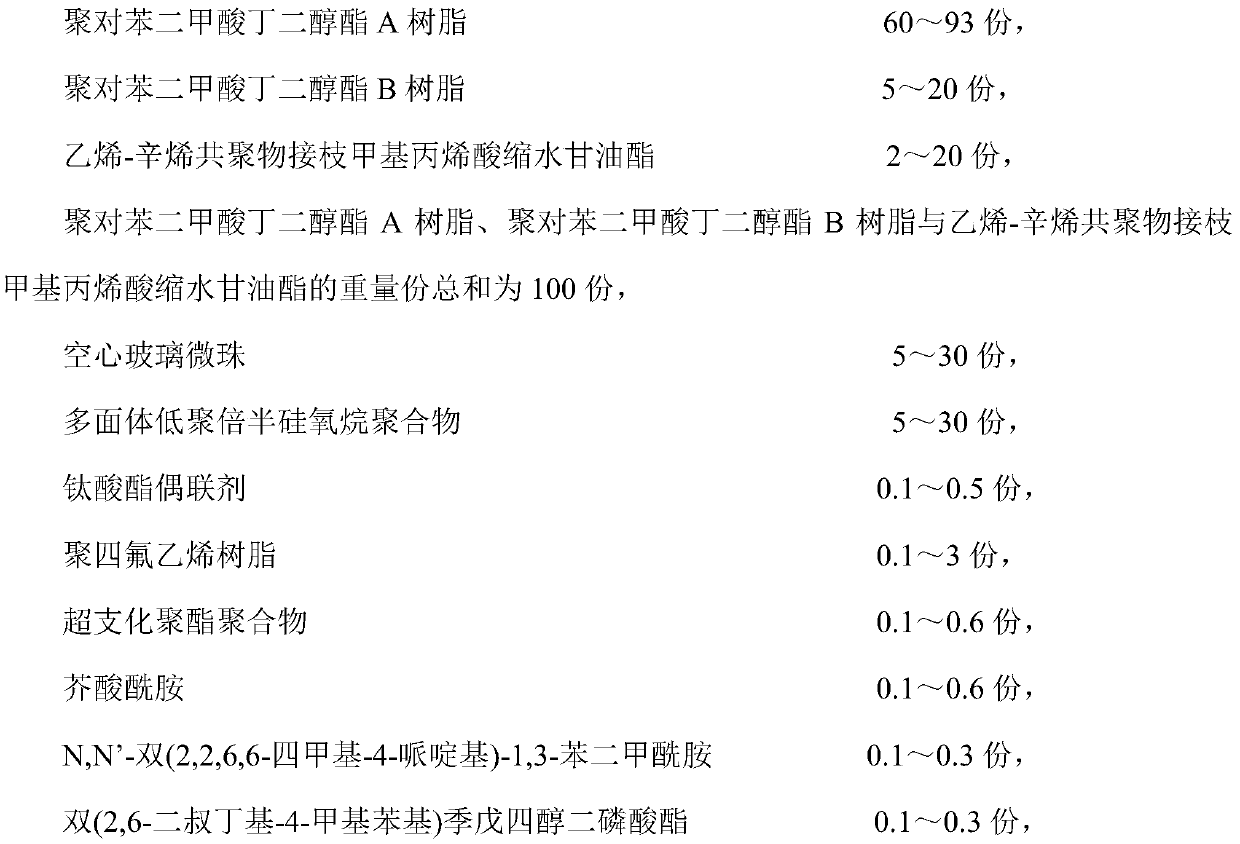

[0086] A polybutylene terephthalate composition of the present embodiment is prepared from the following raw materials in parts by weight:

[0087] 60 parts of polybutylene terephthalate A resin,

[0088] 20 parts of polybutylene terephthalate B resin,

[0089] 20 parts of ethylene-octene copolymer grafted glycidyl methacrylate,

[0090] The sum of the parts by weight of polybutylene terephthalate A resin, polybutylene terephthalate B resin and ethylene-octene copolymer grafted glycidyl methacrylate is 100 parts,

[0091]

[0092] The preparation method of above-mentioned polybutylene terephthalate composition, comprises the following steps:

[0093] (1) After placing the polybutylene terephthalate A resin and the polybutylene terephthalate B resin at a temperature of 90° C. for 8 hours, and then cooling, the cooled polybutylene terephthalate Butylene dicarboxylate A resin and polybutylene terephthalate B resin and the ethylene-octene copolymer grafted with glycidyl meth...

Embodiment 2

[0098] A polybutylene terephthalate composition of the present embodiment is prepared from the following raw materials in parts by weight:

[0099] 93 parts of polybutylene terephthalate A resin,

[0100] 5 parts of polybutylene terephthalate B resin,

[0101] 2 parts of ethylene-octene copolymer grafted glycidyl methacrylate,

[0102] The sum of the parts by weight of polybutylene terephthalate A resin, polybutylene terephthalate B resin and ethylene-octene copolymer grafted glycidyl methacrylate is 100 parts,

[0103]

[0104] The preparation method of above-mentioned polybutylene terephthalate composition, comprises the following steps:

[0105] (1) After placing the polybutylene terephthalate A resin and the polybutylene terephthalate B resin at a temperature of 120° C. for 4 hours, and then cooling, the cooled polybutylene terephthalate Butylene dicarboxylate A resin and polybutylene terephthalate B resin and the ethylene-octene copolymer grafted with glycidyl metha...

Embodiment 3

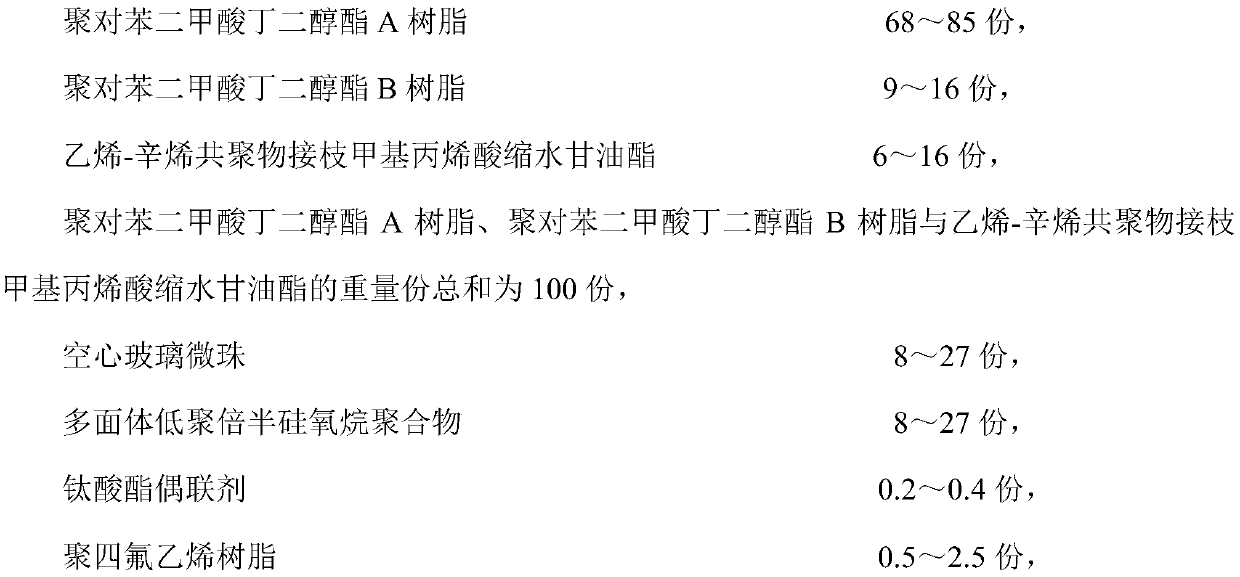

[0110] A polybutylene terephthalate composition of the present embodiment is prepared from the following raw materials in parts by weight:

[0111] 68 parts of polybutylene terephthalate A resin,

[0112] 16 parts of polybutylene terephthalate B resin,

[0113] Ethylene-octene copolymer grafted glycidyl methacrylate 16 parts,

[0114] The sum of the parts by weight of polybutylene terephthalate A resin, polybutylene terephthalate B resin and ethylene-octene copolymer grafted glycidyl methacrylate is 100 parts,

[0115]

[0116]

[0117] The preparation method of above-mentioned polybutylene terephthalate composition, comprises the following steps:

[0118] (1) After placing the polybutylene terephthalate A resin and the polybutylene terephthalate B resin at a temperature of 100° C. for 6 hours, then cooling, the cooled polybutylene terephthalate Butylene dicarboxylate A resin and polybutylene terephthalate B resin and the ethylene-octene copolymer grafted with glycidy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com