A method for preparing amorphous coatings by ultrasonic shock-assisted ultra-high-speed laser cladding

A technology of ultrasonic impact and laser cladding, which is applied in coating and metal material coating process, etc., can solve the problems of difficult large-area preparation of amorphous coating, low preparation efficiency, low coating density, etc., and achieve the elimination of penetration permanent crack defects, improved corrosion resistance, and reduced material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and specific implementation cases.

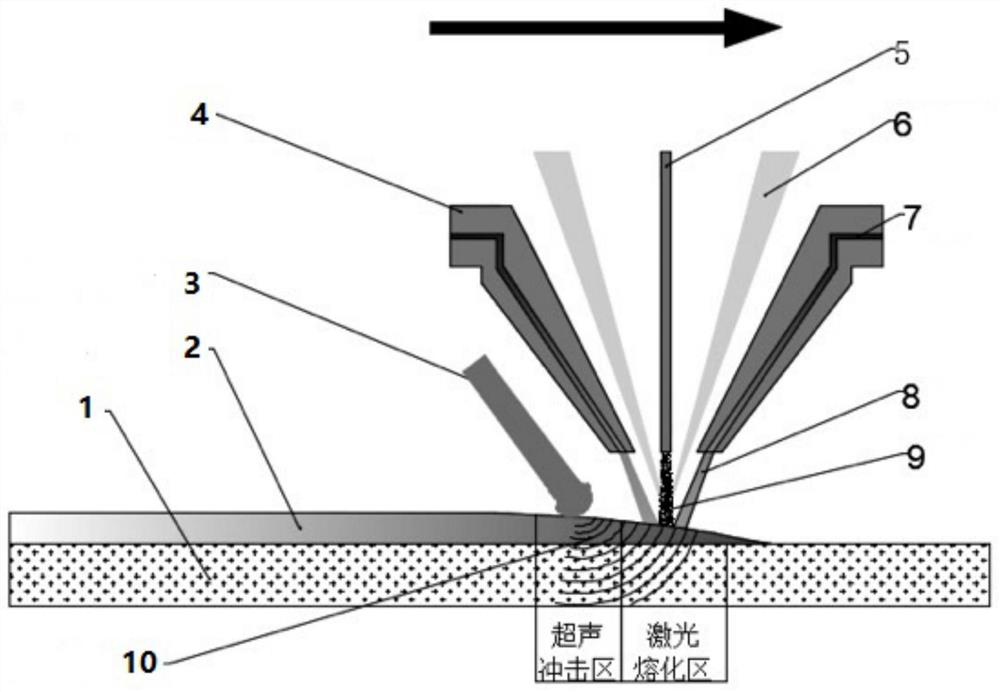

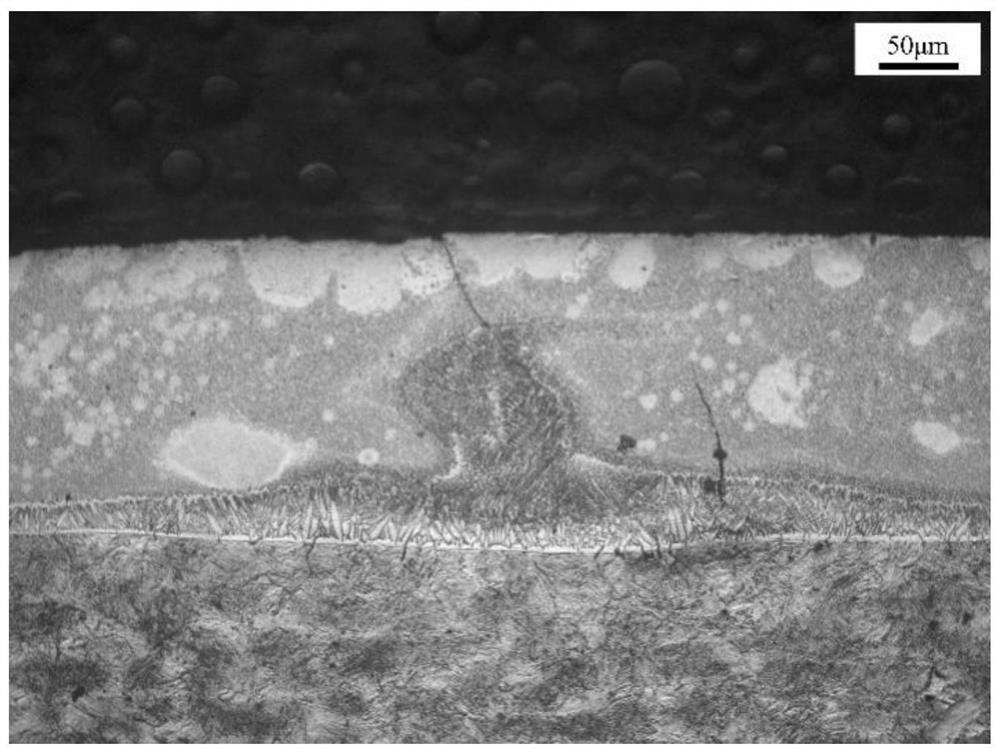

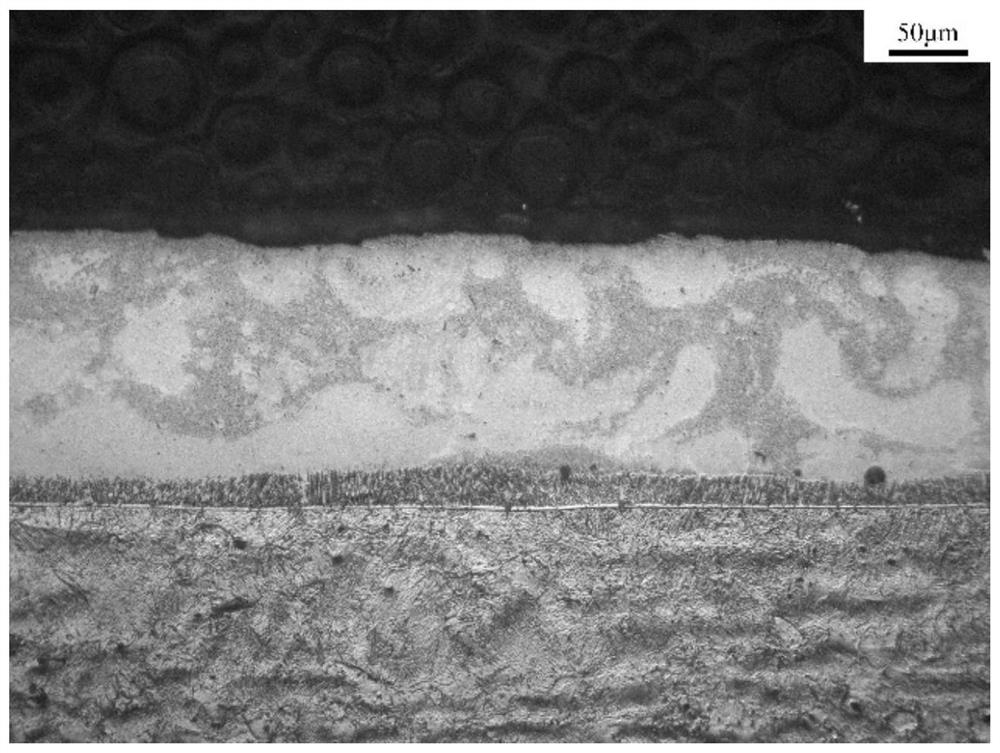

[0024] The invention provides a method for preparing amorphous coating by ultrasonic impact-assisted ultra-high-speed laser cladding, which integrates ultra-high-speed laser cladding technology and ultrasonic impact micro-forging technology and uses them in combination; this innovative design makes full use of ultra-high-speed laser cladding technology. The principles of "rapid solidification" of laser cladding technology and "controlled solidification", "stress relief" and "microscopic defect elimination" of ultrasonic impact micro-forging technology realize high-efficiency and high-quality manufacturing of amorphous coatings.

[0025] The ultra-high-speed laser cladding technology is characterized in that the additive material and the surface of the high-speed moving base material are simultaneously melted and rapidly solidified and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com