Boron diffusion method of solar cell and manufacturing method of solar cell

A solar cell and diffusion method technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problems of poor uniformity of diffusion resistance and product performance consistency affecting the conversion efficiency of solar cells, etc. Achieve good diffusion uniformity, improve diffusion uniformity, and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand and illustrate the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

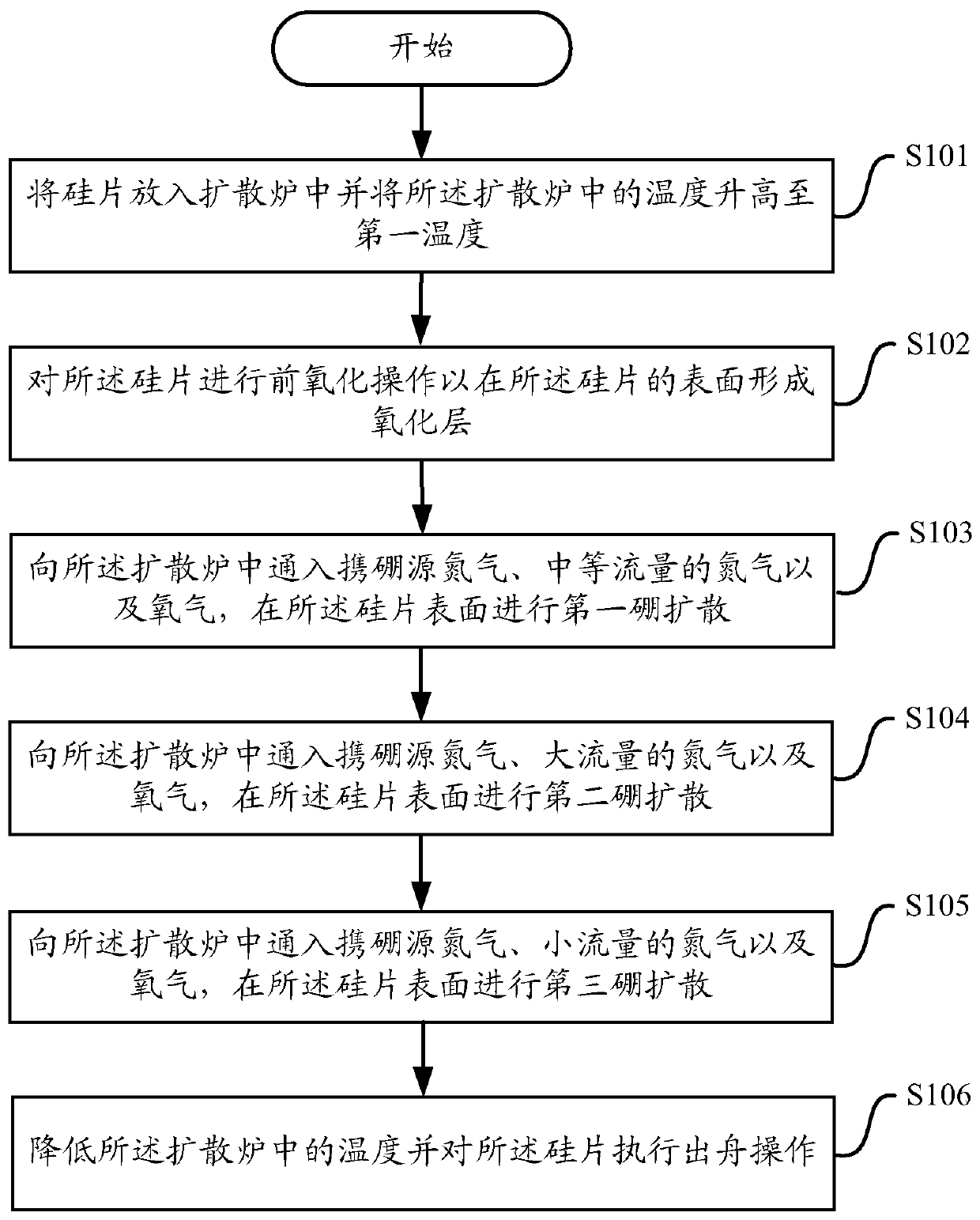

[0030] The invention provides a method for boron diffusion of solar cells. Please refer to figure 1 , figure 1 It is a flowchart of a boron diffusion method for a solar cell according to a specific embodiment of the present invention. As shown, this diffusion method includes:

[0031] In step S101, placing the silicon wafer into a diffusion furnace and raising the temperature in the diffusion furnace to a first temperature;

[0032] In step S102, performing a pre-oxidation operation on the silicon wafer to form an oxide layer on the surface of the silicon wafer;

[0033] In step S103, introducing boron-carrying source nitrogen gas, medium-flow nitrogen gas and oxygen gas into the diffusion furnace, and performing the first boron diffusion on the surface of the silicon wafer;

[0034] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com